Latest Blog

Laser processing of ceramics (laser cutting, laser drilling, laser marking)

Aug 21 , 2022Laser processing of ceramics (laser cutting, laser drilling, laser marking)

Ceramic is a functional material with high melting point, high hardness, wear resistance and oxidation resistance. It is also a good insulator in the fields of military industry, aerospace, high-end PCB and so on. With special mechanical, light, sound, electricity, magnetism, heat and other characteristics, it is mainly used for ceramics in military, aerospace, 3C and other industries. Due to the functional characteristics and performance characteristics of ceramic materials, the breakthrough of laser technology meets the needs of ceramic processing, making it high precision, good processing effect and fast speed in the processing process, thus increasing the processing difficulty. The traditional processing method mainly adopts CNC machining, which is slow and low in precision. This method is increasingly inappropriate as it requires higher precision. Under this premise, the continuous breakthrough of laser technology has gradually gained a voice in ceramic cutting and marking.

Advantages of laser cutting and marking: The advantage of laser cutting is that the laser spot is small, which means that the cutting precision is very high. Laser cutting is a non-contact processing method that does not create stress. The contact between the traditional processing method and the material will inevitably affect the precision and efficiency of the processing, so the laser cutting efficiency is high.

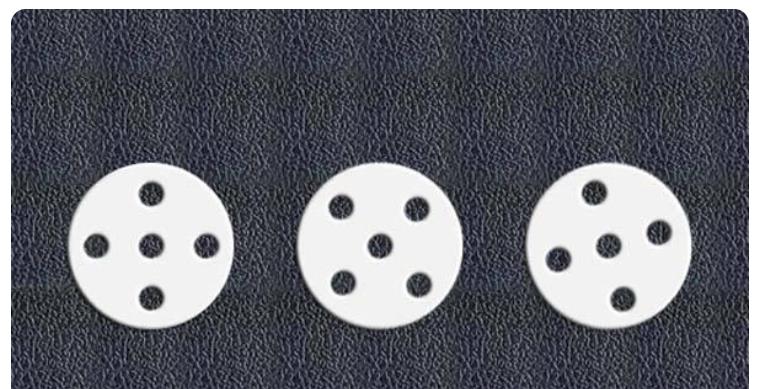

In terms of ceramic labels, the ultraviolet laser has a small focusing point, and the label accuracy can reach 0.2mm. The label has good visual effect, long label effect, wear-resistant, non-fading, clear and layered. Especially on the basis of precision labels, it has stability and advantages, which cannot be achieved by other lasers. In mechanical, chemical, electronic, aerospace and other technical fields, the application of ceramics has expanded from daily life and industrial production to broad market prospects. As a ceramic processing tool, the importance of laser is self-evident. Infrared picosecond laser, narrow pulse width, high peak power, small focus, small thermal influence of cutting ceramics, no burr, high cutting precision. In terms of marking, the marking accuracy is high and the marking effect is clear.