years of RFH laser

About Us

The leading solid state laser manufacturer

About Us

The leading solid state laser manufacturer

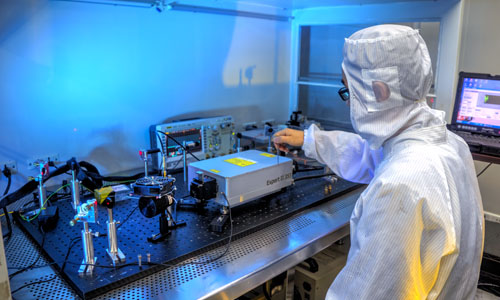

As the leading industrial solid-state laser manufacturer, RFH laser company offer 355nm ultraviolet laser, 532nm green laser and customized laser for a broad range of commercial, industrial, and scientific applications. After 13 years of development, RFH now has an industrial laser oriented R&D team made up of top professionals and experts from both home and abroad. Its R&D departments cover engineering, laser and electric. In addition, RFH has obtained 10 national patent certificates and 14 software copyright certificates and is certified as “High Tech Enterprise”, “Shenzhen High Tech Enterprise” and “Software Enterprise” as well as the council member of Guangdong 3D Printing Industry Innovation League and Guangdong Laser Industry Association. Orienting to serve laser end users and system integrators, RHF’s products cover from green laser to deep UV laser whose pulse power, average power and pulse repetition rate are applicable in various laser applications, including consumer electronics, electronics circuit, packaging & printing, solar power, lithium battery, semiconductor microelectronics, panel display, jewelry, biomedicine, automobile and aerospace. RFH lasers are widely used in SLA 3D printing, high precision marking & drilling & cutting, laser welding, laser plastic & metal welding, laser medicine, surface removal, wire stripping and laser inner engraving. RFH has a complete product line and rigorous quality control system. Production is performed in dust-free workshop. Rigorous control by QC department in incoming materials, production, product check & acceptance and delivery guarantees the performance and quality of the product. Rigorous quality control system A.Purchasing Work with top brand suppliers of home and abroad to ensure quality of each component B. Pre-production quality check Perform quality check on each component and only 100% qualified one can be made into production plan C. Production in dust-free plant Clean production environment, Ensure dust free and pollution free production D . Rigorous assembling steps Arranging assembly line -> testing sealing property -> commissioning, each step helps guarantee the product quality E.Finished product testing All the finished lasers must pass the aging test; parameters like power, beam quality, beam circularity and beam-pointing drift must 100% reach the standard F.Warehouse-in inspection Follow the “product warehouse-in inspection standard” and only 100% qualified laser can be put into the warehouse G.Delivery Before delivery, turn on the laser to test again its power, beam circularity and beam-pointing drift and only when those parameters are 100% accurate can the laser be delivered, which guarantees the consistency of laser operation in different conditions H.After-sales service Provide 18 months of warranty and 24 hours after-sales respond service. Set up branch offices in Wuhan and Suzhou RFH - The leading industrial solid-state laser manufacturer For over 17 years with excellent long term stability and exceptional good beam quality Production in dust-free plant & rigorous quality control system From purchasing, pre-production quality check, assembling, finished product testing, warehouse-in inspection, pre-delivery testing to after-sales service, each step is under control to make sure product quality and consistency in both machine parameters and actual running parameters. This is what makes RFH laser lasts longer than its peers. Top professional team, independent R&D in laser oriented power supply control system There is a one-to-one correspondence between power supply and laser. The stability of power supply control system determines if the laser can maximize its performance during operation. RFH Laser has independent R&D in power supply technique which enables timely update and improvement of power supply control system module based on the laser’s need. 12-year experience in R&D and a top professional team make RFH laser a reliable and stable laser system. Core components of oversea brands with guaranteed quality Pumping, Q-switching and other core components adopt oversea brands. Work with top brand component suppliers of home and abroad. Each component is guaranteed with its quality from the beginning of materials purchasing. This is why users can trust RFH laser. Power supply+laser head+cooling system sold in a group Being client-oriented, RFH offers proposal of selling the whole laser system in a group so that the laser system can maximize its performance while maintaining its stability. Full-digital display, supporting communication with computer, capable of laser’s remote control Each laser developed and produced by RFH can always remain high quality in industrial and extreme conditions of scientific research. With stable beam quality, high efficiency, best cost performance and high reliability, RFH has earned good reputation in different industries at home and abroad. After 17-year development, RFH has become a reputed brand in nanosecond laser industry.

The UV laser series products have stable power and high integration. Small size, long life, excellent beam quality, high stability, and can be customized according to user needs.

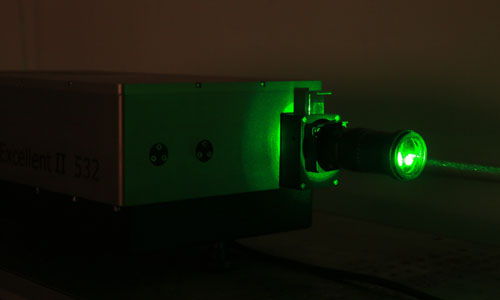

Green laser is perfect for glass marking, thin film etching and surface treatment for most of the metals and non-metal materials, such as removing the oxide layer from the metal surface.

The UV laser and green laser series products have stable power and high integration. Small size, long life, excellent beam quality, high stability, and can be customized according to user needs.