Latest Blog

Why UV laser marking machine is very suitable for marking wire and cable

Nov 17 , 2022Why UV laser marking machine is very suitable for marking wire and cable

The packaging of common products in daily life has information such as the date of production, the expiration date of the product, the place of production, the ingredients contained in the food, and the storage conditions. In the past, most of these information were printed with inkjet printers, which were easily changed and erased, and could not play a very good anti-counterfeiting role. For example, cable and pipe products, the production technology threshold of this kind of products is low, the product quality varies, and counterfeit and shoddy products occur from time to time and are difficult to control. It is often difficult for consumers to judge whether the products are genuine. Thousands of households use electricity safely. In addition, many cables and pipes are exposed or buried underground for a long time, and the surface marks are easily washed away by rain or touched by hands, causing troubles for users in later use. Some pipes used in the food and pharmaceutical industries have higher requirements, and the materials and printing materials are required to be non-toxic, harmless, and not easy to volatilize and fade. Therefore, inkjet coding marks are often worn off and cannot be traced back, and it is difficult to continue to function. At the same time, with the continuous increase in the production cost of wire and cable manufacturers, inkjet printer consumables for marking have become invisible costs that cannot be compressed by manufacturers. The homogeneity of products in the wire and cable industry and excessive competition among enterprises have become increasingly prominent. Cable manufacturers face dual pressures from both external and internal environments. The country attaches great importance to the standardized development of the cable industry. In order to standardize the use of unified standards, the country has issued a number of standards, such as GB/T5310, GB/T8163, GB3087, etc. Regardless of whether it is a flexible cable or a hard pipe, it is stipulated that the manufacturer must indicate the origin, specification, manufacturer and product information on the product packaging or outer box. At this time, there is an urgent need for a permanent marking information, no Poisoned processing tools appear.

The application of laser technology has been widely used in various industries, and its excellent performance advantages have brought new vitality to modern industrial technology. As an advanced marking equipment, laser marking machine has become an irresistible trend in the application of wire and cable. Because of its many advantages, it is replacing traditional coding equipment. The emergence of equipment makes the application advantages of laser marking in the field of wire and cable more obvious, and it has become the latest choice of wire and cable manufacturers. With the advantages of zero consumables, high stability, maintenance-free, beautiful marks and no falling off, the laser marking machine "shows its strengths" in the wire and cable industry! For wire and cable users, clear and accurate identification is a way to identify the brand. The corresponding date, batch number, brand, serial number, QR code and other information are marked on it, which can effectively resist counterfeiting by some unscrupulous merchants. , Shoddy and cross-selling, effectively standardize the current wire and cable market, and also play a very important role in improving the quality of wire and cable. At the same time, the entire processing process of laser marking is controlled by computer software, which not only has high processing flexibility, but also is accurate, and can effectively reduce the defective rate of wire and cable product processing.

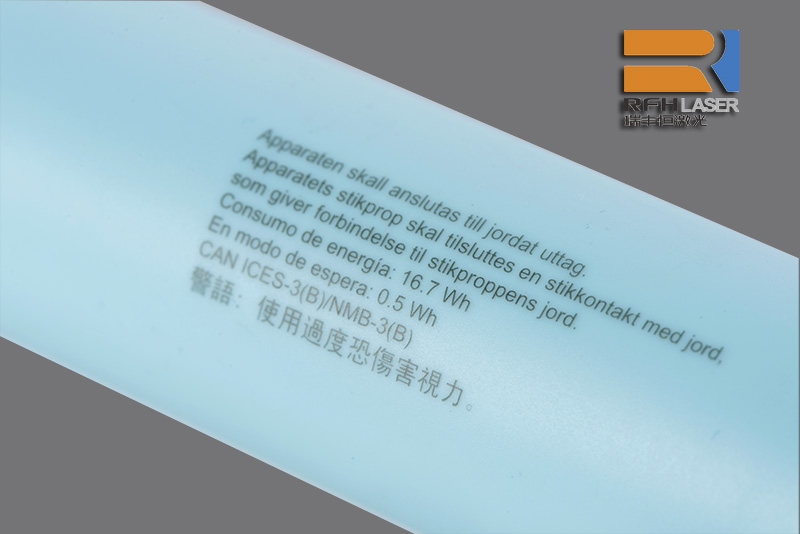

At present, the lasers used for cable coding are mainly divided into: carbon dioxide laser marking machine, fiber laser marking machine and ultraviolet laser marking machine. Among them, carbon dioxide laser marking machine and fiber laser marking machine are discolored by burning the surface of the cable, which will Damage to the surface of the cable and smoke. The principle of UV laser marking machine processing is realized by photochemical ablation, that is, relying on laser energy to break the bonding between atoms or molecules, so that the material is destroyed by a non-thermal process to achieve a color change reaction. This kind of cold processing has special significance in laser marking processing, because it is not thermal ablation, but a cold peeling that does not produce "thermal damage" side effects and breaks chemical bonds, so it is not harmful to the inner layer and nearby areas of the processed surface. Produce heating or thermal deformation and other effects. , so it can be used for ultra-fine marking and special material marking. It is the first choice for customers who have higher requirements for marking effects. The laser marking is exquisite and will never fall off and fade, which perfectly solves the disadvantages caused by the traditional coding method. At present, in non-transparent plastic products, soft film packaging, cable pipes and other industries, ultraviolet light has good application due to its good absorption and small thermal damage. In the future, more and more cables will use ultraviolet laser marking machines to print codes.

Advantages of wire and cable laser marking machine

The dedicated marking software can provide consistent and real-time marking information without affecting the continuous operation of the entire production process.

The logo after laser marking is permanent, will not wear and fade, and the printed characters can be as small as 0.8 mm, which can meet the printing requirements of tiny information, and can print various complex graphics or factory logos and standard certifications, such as TUV, UL, CE, etc.

It can meet the general marking requirements, and at the same time, the stable running quality and high-definition laser marking meet the clear, durable and easily identifiable marking requirements of wire and cable products.

Marking at different angles at any time, 360-degree marking angle, circular, curved, strip, etc., or print factory logo, specification, date and other product information on the bottom, side, top, etc. conform to the standards and specials of the wire and cable industry application requirements.

Suitable for high-speed production line marking (7000mm/s).

The laser directly reacts with the surface of the material, presenting a marking effect, without consumables.

Zhongdiao Laser provides customers with a complete set of system solutions for laser marking, laser welding, and laser anti-trafficking. Free proofing, product selection, technical guidance, installation training and other full-life cycle and full-process services, whether it is a high-end customer with high requirements for processing quality or a small and medium-sized customer with ordinary needs, you can find a suitable solution in Zhongdiao Laser laser marking machine. Zhongdiao Laser kindly reminds you: before purchasing a laser marking machine, you must first check the material, material, type, type of the product to be marked, and whether it needs to meet the production method of the assembly line. Through these points, we can judge which kind of marking machine the enterprise needs, so that the analysis and selection can reduce unnecessary costs and improve the efficiency of production work.