Latest Blog

How To Choose SLA, DLP, LCD Three Kinds Of UV laser Light Curing Resin 3d Printer?

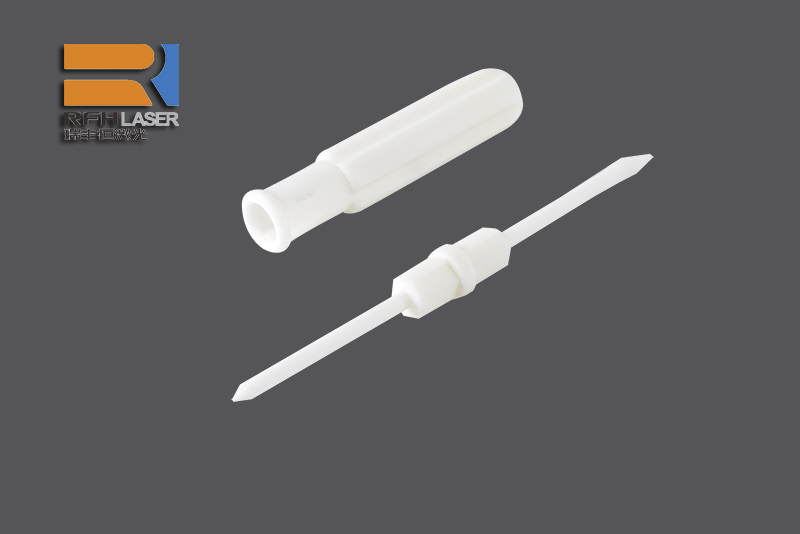

Dec 02 , 2022UV Laser curing SLA 3D SAMPLE

With the mature development of 3D printing technology, various types of 3D printers have penetrated into the production life of people. Among them, light-curing resin 3D printers have become a popular choice for most people who want to make high-precision models for a variety of uses, such as for companies, factories, creators, home use, etc.

1. SLA / DLP / LCD all belong to the category of light curing, using photosensitive resin for printing, but there are advantages and disadvantages between the technologies. SLA uses a laser to cure the resin and is the most traditional and widely used 3D printing technology, with few restrictions on print size, but print speed, accuracy and detail are generally not as good as DLP / LCD 3D printers. SLA 3D printers are usually larger and more suitable for printing large prototypes or mass production scenarios.

2. DLP 3D printing technology first appeared in 2000, DLP 3D printing technology mainly uses UV laser projectors to project product cross-sectional graphics onto the surface of liquid photosensitive resin, so that the irradiated resin is photocured layer by layer. Unlike SLA 3D printing technology with single point exposure, DLP 3D printing technology uses surface exposure, which can greatly improve the printing speed, and DLP 3D printing technology is generally better than SLA 3D printers in terms of accuracy and surface quality.

Most DLP 3D printers use a down-illuminated technology solution, where the light source is below the resin tank. The advantage of this solution is that very little resin is required to start printing, but the size of the print is also constrained due to the limitations of off-shape. dLP 3D printers are usually smaller in model size and can be easily deployed in office environments and are more widely used in dentistry, product development validation, research and education.

3. LCD (mSLA) is similar to DLP 3D printing technology, but instead of using a projector to produce an image, it produces a specific image through the deflection of the LCD liquid crystal. Thanks to the mature upstream chain of LCD 3D printing technology, LCD 3D printers can usually achieve higher resolution and smaller pixel dot size than DLP 3D printers. However, due to technical limitations, the optical power of LCD 3D printers is generally lower than that of DLP 3D printers, resulting in slower printing speeds. However, LCD 3D printers are more affordable than DLP 3D printers, which makes them very popular in the market.

l Print size (a device with a large print size that enables rapid iteration of design prototypes as well as rapid production of small batches.)

l Print accuracy (the higher the resolution and smaller the pixel dot size, the clearer the surface details and textures of the printed object; the more advanced the optical design, the higher the accuracy of the printed object and the ability to accurately render the design prototype.)

l Print speed (when evaluating print speed, we generally need to limit the material and layer thickness. Even on the same machine, different layer thicknesses and different materials can lead to huge differences in print speed)

l Material openness (Some 3D printers only allow users to use dedicated resin materials, which is a very big limitation, while 3D printers with open systems are compatible to use more third-party materials.)

l Nesting/slicing software (Nesting and slicing is the first step in 3D printing, and a good software can make pre-processing fast and easy. (Most 3D printer companies offer free software trials that users can simply try before purchasing.)

l Post-processing (Resin 3D printed samples need to be cleaned and post-cured. Post-cured samples are stronger and less deformed. (Therefore, equipped with a complete cleaning machine and curing box can effectively improve efficiency and reduce labor costs.)