Latest Blog

The difference between 355nm ultraviolet laser and 1064 nm infrared laser

Dec 16 , 2022The difference between 355nm ultraviolet laser and 1064 nm infrared laser

Infrared lasers and ultraviolet lasers are the two most widely used lasers, so what is the difference in the processing of these two lasers? How to choose laser marking with higher requirements?

Infrared YAG laser with a wavelength of 1.06 μm is the most widely used laser source in material processing. However, many plastics and some special polymers (such as polyimide) that are widely used as substrate materials for flexible circuit boards cannot be finely processed by infrared treatment or "thermal" treatment.

Because "heat" deforms the plastic, damage in the form of carbonization occurs on the edge of the cut or drilled hole, which may lead to structural weakening and parasitic conductive pathways, and some post-processing steps have to be added to improve the processing quality. Therefore, infrared lasers are not suitable for processing some flexible circuits. In addition, even at high energy densities, the wavelength of infrared lasers cannot be absorbed by copper, which further severely limits its application range.

The output wavelength of ultraviolet lasers is below 0.4 μm, which is the main advantage of processing polymer materials. Unlike IR processing, UV microprocessing is not thermal in nature, and most materials absorb UV light more readily than IR light. High-energy ultraviolet photons directly destroy molecular bonds on the surface of many non-metallic materials, and parts processed by this "cold" photoetching process have smooth edges and minimal carbonization.

Moreover, the characteristics of the short wavelength of ultraviolet light are superior to the mechanical micro-processing of metals and polymers. It can be focused to sub-micron points, so it can process fine parts, even at low pulse energy levels, it can also get high energy density, and effectively process materials. Micro-holes are in the industry. The application in has been quite extensive, and there are two main ways of formation:

One is to use an infrared laser: to remove the material by heating and vaporizing (evaporating) the substance on the surface of the material, this method is usually called thermal processing. Mainly adopt YAG laser (wavelength is 1.06μm).

The second is to use ultraviolet laser: high-energy ultraviolet photons directly destroy the molecular bonds on the surface of many non-metallic materials, so that the molecules are separated from the object. This method does not generate high heat, so it is called cold processing, mainly using ultraviolet laser (wavelength is 355nm).

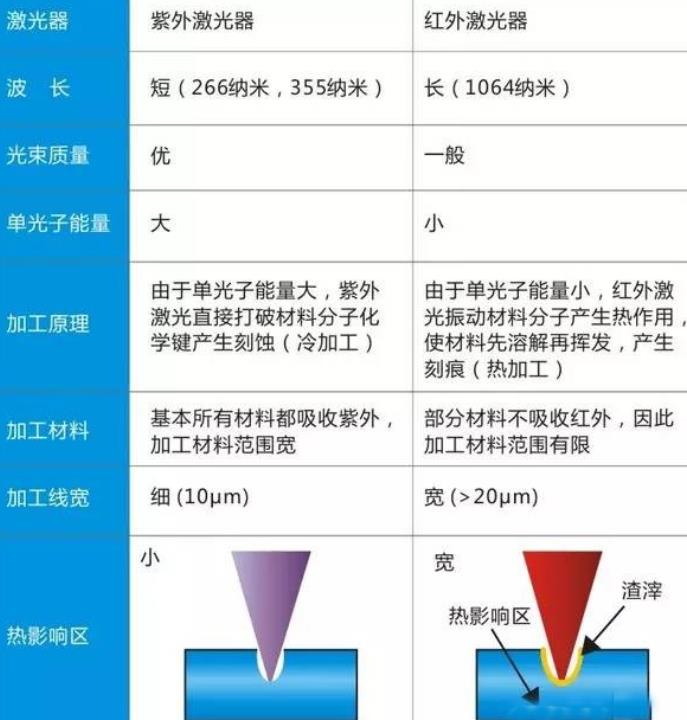

The comparison between ultraviolet laser and ordinary infrared laser is as follows:

Ultraviolet lasers and infrared lasers (the difference between ultraviolet lasers and infrared lasers)

Through the above table, it is not difficult to find that the ultraviolet laser has an absolute advantage in ultra-fine marking and special material marking due to its extremely small focus spot and minimal processing heat-affected zone.