Latest Blog

why we need set parameters of UV laser marking machine on/off/end/corner delay

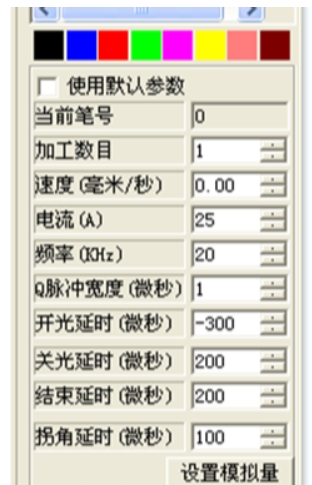

Oct 13 , 2023This is because the light output speed of the laser is inconsistent with the swing speed of the galvanometer motor. The laser light output speed is generally faster, while the galvanometer motor is mechanically slower than the laser. If we want the marking effect to be good, we must set these delay parameters. That is to say, when the laser marking machine is working, it first needs to wait for the oscillating galvanometer of the galvanometer to control the light to reach the starting point of the marking, and then emit light. It is better to start writing at this time. A single graphic, at the end of marking, is also the graphic after the galvanometer is finished, and the light is turned off after the graphic is sealed.

The delay time of laser turning on when marking starts. Setting the appropriate switch-on delay parameter can remove the “match head” that appears at the beginning of marking, but if the switch-on delay parameter is set too large, it will lead to the phenomenon of missing pens at the beginning. It can be a negative value, and the negative value marks the laser to emit light in advance. Generally, the switching delay of fiber lasers is set to a negative value, while other lasers, such as end-pumped lasers, are set to a positive value.

The delay time for the laser to turn off at the end of marking. Setting an appropriate light-off delay parameter can eliminate the non-closing phenomenon when marking is completed, but if the light-off delay is set too large, it will cause a "match head" at the end. Cannot be negative.

The time to wait for the laser to turn off completely. The laser needs a period of response time from the time the light-off command is issued until the laser is completely turned off. Setting an appropriate end delay parameter is to give the laser sufficient light-off response time, so as to achieve the purpose of turning off the laser completely and then marking the next time. Appropriate end delay parameters can eliminate the "ghosting" phenomenon during marking, but if the end delay is too large, it will affect the processing speed. Cannot be negative.

The delay time between each segment when marking. Setting appropriate corner delay parameters can remove the rounded corner phenomenon when marking right angles, but if the corner delay setting is too large, the marking time will increase, and there will be key phenomena at the corners. Cannot be negative.