Latest Blog

RFH UV laser cuts earphone film to improve music quality

Jun 18 , 2021RFH UV laser cuts earphone film to improve music quality

With the development of the social age, our perception of headphones has undergone different changes. At first, I was afraid of disturbing others by wearing headphones, but now I am afraid of disturbing others. More and more young people choose to wear headphones and enjoy them in public. This phenomenon has led to the rapid expansion of the headset market today, and has become an important "power point" for the mobile phone industry to expand new categories. According to the latest data, global headset shipments will increase by 78% in 2020, and it is expected that shipments will reach 310 million units in 2021, an increase of more than 33%, and demand is strong.

As people have higher and higher requirements for auditory effects, the requirements for their carrier-earphones have also increased. Sound quality has become an important criterion for people to choose headphones. The main factor that affects the sound quality of headphones is the quality of the speaker unit, and the diaphragm is one of the key components. The diaphragm is actually a component that is very sensitive to changes in the magnetic field. When an electrical signal passes through the coil, the magnetic field changes, causing the diaphragm to be deformed by force. Due to the rapid change of the electrical signal, the diaphragm vibrates at a high speed, and then is transmitted to the air through the vibration of the diaphragm, thereby generating sound waves, which is the sound we hear. In this process, the quality of the diaphragm determines the overall headset Quality.

02

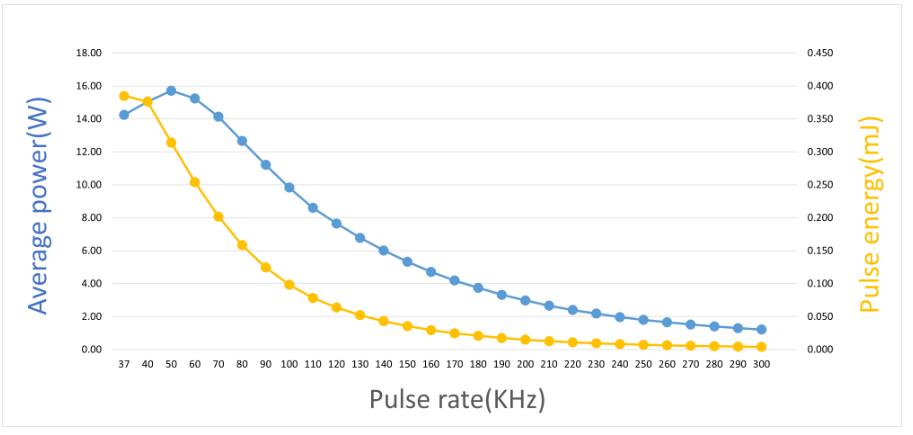

The diaphragm is a very fragile thing. The traditional processing method uses a blade to scrape. The efficiency of manual scraping is very low, and it is easy to scratch the product, and the yield is low. According to market development needs, RFH Laser's newly launched S9 series pulsed ultraviolet solid-state lasers. Compared with products of the same type, the S9 series has a smaller volume, a more refined design, and a more stable light output.

The cutting function of S9 series ultraviolet laser plays an important role in the production of earphone diaphragm. This equipment perfectly shows the speed of the laser. Through the coaxial CCD + servo platform, the laser uses sub-regional photography to cut at one time. It is equivalent to the time that it takes one hour to finish the job manually before, so the laser can finish the job in tens of seconds. It is not only efficient and fast, lower cost, but also not easy to damage the product, and the yield rate is high. It can realize the fast and accurate cutting of various earphone diaphragm products.

When cutting non-metallic materials, the original S9 series UV laser uses 354.7nm laser wavelength to make it easily absorbed. The poor thermal conductivity and low evaporation temperature make the absorbed beam almost transmitted into the material and irradiate the spot. It vaporizes instantly to form initial holes and enters the virtuous cycle of the cutting process. Under the correct control process, the edge seam of the cut earphone film is smooth and flat, without burrs and bubbles.

At the same time, RFH S9 series ultraviolet lasers also have obvious advantages in other applications of laser cutting:

Smooth cutting and high efficiency;

Non-contact processing, no damage to the material;

Clean, safe and pollution-free;

Wide range of processing materials, advanced processing technology and strong flexibility;

Intelligent interconnection, unique Q-adjusting control technology, full digital intelligent power control, simple operation.

High cost performance, mature technology, perfect after-sales service