With the development of flexible circuit board from single-sided to double-sided, multilayer, electronic engineers require flexible printed circuit board (PCB) and rigid-flex PCB with high precision, high density and high reliability. How to process flexible PCB outline? A typical router in FR4 PCB profiling won’t work on flexible printed circuit (FPC) because the spindle won’t cut the polyimide or polyester material correctly.

There are several different methods for processing outline of individual and panel flexible PCB and coverlay, including hand trim, steel rule die, punching die, and laser cutting. As a professional flexible circuit manufacturer, generally we use Punching Die and Laser Cutting to make FPC outline upon different production quantity requirements. Low volume and flexible PCB prototypes are outlined by laser cutting, and mass production is outlined by Punching Die.

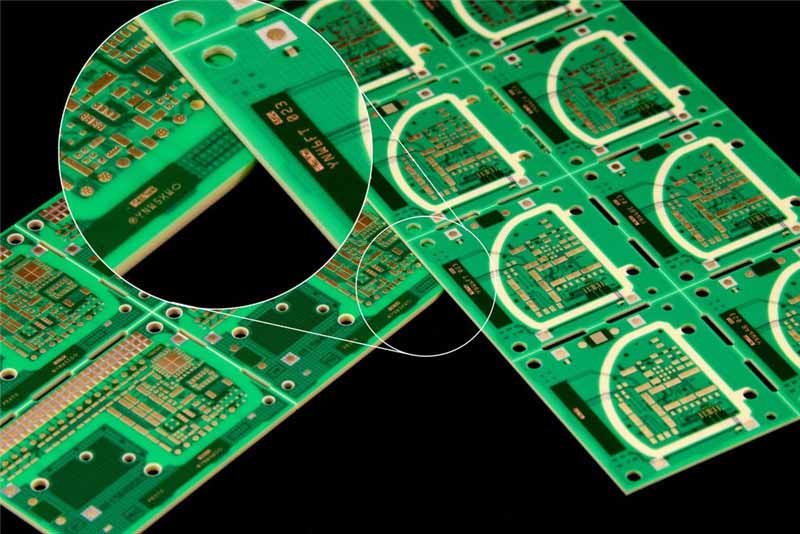

View more to check our Flexible & Rigid-flex PCB Capabilities

Flex PCB Outline Processing by Laser Cutting

Laser Cutting

35w green laser cutting pcb: https://www.rfhtech.com/expert-iii-532-green-laser-35w_p16.html

We use laser cutting machine for processing outline of the flex PCB prototype production. The laser machine can also be used to cut coverlay, PI Stiffener, FR-4 Stiffener, ZIF fingers (copper contacts), and thin rigid-flex PCB. The FPC outlining precision of laser cutting is much higher than that of steel rule die and punching die. For prototype flexible PCB production, the camera in the laser machine header can capture the fiducial marks on the flexible circuits to realize recognition and ensure accurate outline precision.

FPC Outline by Punching Die

.png)

FPC Outline Processing

Another FPC outline processing method is punching with punching die and PCB punching machine, which is mainly used in the mass production of flex circuits and rigid-flex board. Compared to laser cutting, the cost of punching is lower but with higher work efficiency. We have 6 sets PCB punching machine and a punching die warehouse in a special storage environment. To be the leading flexible PCB manufacturer, we are able to produce high volume flex PCB and rigid-flex PCB with a few designs at the same time.

The technicians who handle the punching machine to processing flexible circuits outline are highly trained and skilled, and they conduct each process carefully under the strict flexible PCB manufacturing standards to ensure high yield.