Mexico customer order high power 355 nm laser source for laser frosting of glass surfaces

Dec 10 , 2022Mexico customer order high power 355 nm laser source for laser frosting of glass surfaces

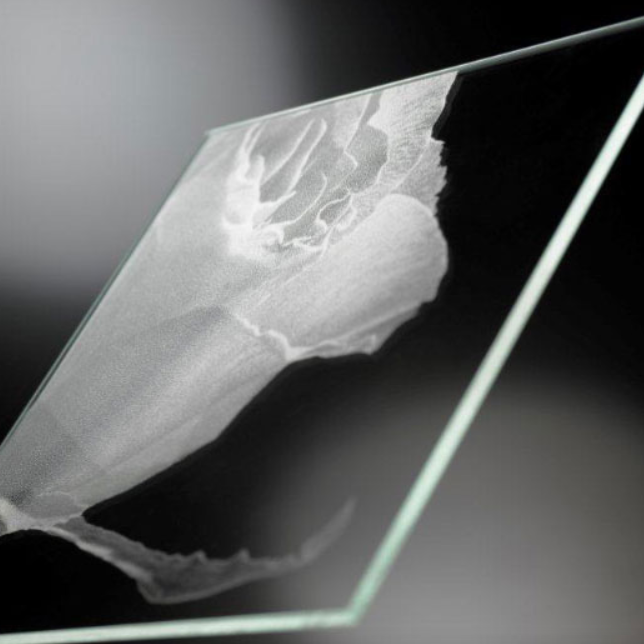

The laser frosting of glass surfaces is a real alternative to classic sandblasting, chemical techniques or even to printing technology. The laser created frosting has a lower dirt sensitivity compared to conventionally frosted surfaces.

The surface structure created by a laser has a different visual effect than sandblasted or etched surfaces. Therefore a pattern can be created with a laser on a glass surface, that was previously frosted by sand blasting or etching.

By using laser technology the finest graphic structures such as lines and dots can be created - whereas this type of structures can only be produced with conventional techniques at a very high cost.

The creation of grey shading and scale is absolutely no problem with a laser. Photographs and graphics can therefore be applied to glass without the loss of any quality.

Surface frosting can be created with the laser on all kinds of glass. Even safety or toughened glass can be processed using the laser process developed

This means that nothing stands in the way for the surface structuring of all-glass doors such as exterior elements, shower enclosures and more. Even coated glass can be processed with our laser process.

Glass coatings such as mirror, chrome, ceramic and organic coloured layers are easy to perforate or remove by laser while the sensitive glass surface beneath is frosted simultaneousely.

The laser is less suitable for the production of full-area frostings. Here, the classic matting processes have an advantage due to the shorter process times.

Large-area motifs with homogeneous scan fields with overlapping are also possible.

But wherever the application of decors, detailed graphics and photo motifs is required, the laser really shows its advantages. Thanks to cerilas laser technology, the otherwise costly and labor-intensive manual process steps are no longer necessary.

By using the laser technology , you transfer your design directly from the computer to the glass. Forget about refilling ink, cleaning screens, printing heads, or the disposal of blasting material. From now on, let work with light - a tool that never gets dull.