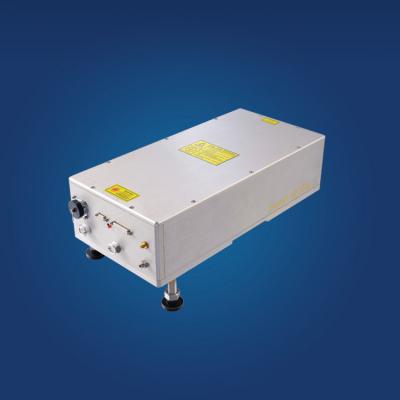

P-ir-1064 series picosecond infrared solid-state laser, with a power of 30w, compact structure, ingen design, good beam quality (M2<1.3), and stable power. This series of lasers is mainly used for high-precision marking and cutting of glass, drilling cutting of sapphire, marking/drilling micro holes/cutting of ceramics, and cutting of LCD/OLED display panels.

New P-ir-1064 infrared laser product features:

1. Laser wavelength 1064nm, the repetition frequency coverage range wide (300kHz to 1500kHz); the power range is 30w

2. Superior beam quality (M²<1.), strictly guaranteed in all frequency ranges; pulse width <10ps, small thermal affected area during machining

3. Unique Q-switch control technology, suitable various laser application control requirements; longer laser life, more stable operation.

4. Full digital intelligent power control technology, simple operation, convenient monitoring

5. Support communication with computer can be externally controlled by RS232; integrated design, convenient for equipment integration