Research on UV Laser Glass Marking Technology

Aug 17 , 2022Research on UV Laser Glass Marking Technology

This article will guide you to understand and master the processing technology of UV laser marking on glass surface.

one. Glass marking difficulty

When a beam of light hits the glass, some of the light is reflected off the surface, and most of the rest is passed directly through. The same is true for UV lasers. When UV lasers are used to etch the glass surface, extremely high energy density is required. However, if the energy density is too high, cracks or even chipping may occur. If the energy density is too low, the punched points will sink or cannot be directly The surface is etched, so the processing is difficult.

two. Influencing factors

1. flat glass

UV laser marking on flat glass is directly related to the peak power of the laser, the size of the final focused spot, and the speed of the galvanometer.

We have found that sometimes the light from high power lasers does not etch the glass surface, but passes directly through. This is because the peak power of the laser is not enough, or the energy density is not concentrated enough. The peak power is affected by the laser crystal, pulse width and frequency. The narrower the pulse width and the lower the frequency, the higher the peak power of the laser. The energy density is affected by the spot size and the beam quality M2 of the laser beam (the standard for measuring the laser beam, which refers to the value of the laser beam close to the Gaussian beam, Gaussian beam M2=1). The spot size can be changed by using a high magnification beam expander. M2 can only be determined by the beam quality of the laser itself. The smaller the M2, the greater the beam expander magnification, the more concentrated the energy density.

Although some can be etched on the surface of the glass, it still produces the phenomenon of leakage, and some points formed by the pulse will sink into the glass to form an internal engraving. This situation can be improved by using a high peak power laser and a high magnification beam expander. processing effect.

In addition, the time that the laser beam contacts the glass surface also affects the etching effect of the glass surface. Too long contact time may cause the glass surface to be hit too deep, and too short a contact time may cause leakage. We only need to change the scanning speed of the galvanometer to an appropriate value to get a better processing effect. However, it should be noted that the scanning speed is also affected by the frequency of the laser itself, and if the frequency is too low, it will also lead to leakage.

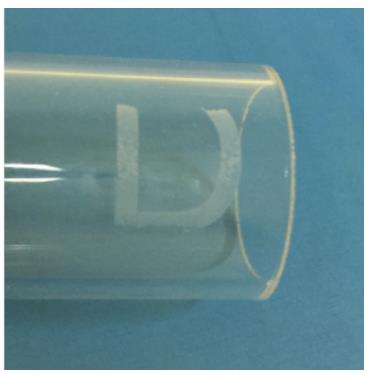

Research on UV Laser Glass Marking Technology

(RFH LASERLP106-5w processed flat glass)

2. Curved glass

Due to the influence of the bending force, the focal depth of the final focused spot and the scanning method of the galvanometer are particularly important to the processing effect, that is, the peak power of the laser, the final focused spot, the scanning speed of the galvanometer, the scanning method of the galvanometer, the focal depth of the spot and the field scope of the mirror, etc. When the energy density reaches the standard, we will find that the effect on the glass surface is worse as it goes to the edge, and it cannot even be processed on the surface. The reason is that the depth of focus is too shallow. The focal depth is affected by the M2 factor of the laser beam, the spot size of the beam expander, and the range of the field lens. The magnification of the beam expander and the range of the field lens both affect the focal length. The shorter the focal length, the more concentrated the energy density and the shallower the depth of focus. Let's take a look at the effects of different depths of focus. As shown in the figure below, when RFH LASER5w laser, SCAN-LAB high-speed scanning galvanometer, F=160 field lens, X10 times beam expansion, X8 times beam expansion, X5 times beam expansion, the effect of etching on the surface of quartz glass :

Research on UV Laser Glass Marking Technology

(X10 times beam expander)

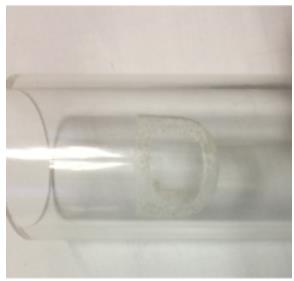

Research on UV Laser Glass Marking Technology

(X8 times beam expander)

Research on UV Laser Glass Marking Technology

(X6 times beam expansion front)

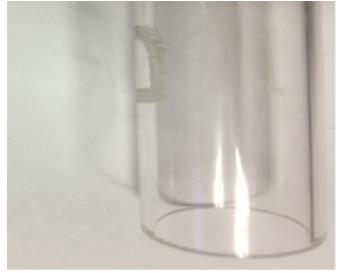

Research on UV Laser Glass Marking Technology

(X6 times beam expander side)

As shown in the above pictures, we can clearly observe that under the 10x beam expansion, the energy density is relatively concentrated and the surface is very delicate, but due to the shallow depth of focus, the lasers on both sides do not work on the surface. Under the 8x beam expansion, for the current curved product, the focal depth and energy are more suitable, and the marking effect is better. However, the 6-fold beam expansion focal depth increases and also reduces the energy density, so there are many leaks and the effect is poor.

Therefore, we conclude that for such glass materials with large curved surfaces and high hardness, a laser with better beam quality and narrower pulse width should be selected, and a suitable beam expander or a 3D variable focus galvanometer should be used to process the glass. products are more suitable.

RFH LASER launched a new 5w~7w (LP106, SP355) water-cooled UV laser for this type of glass marking. The M2 factor of this laser is less than 1.3, which is close to the value of the Gaussian beam (M2=1), which ensures the beam quality; The pulse width can reach 10ns at the frequency of 30KHZ, which ensures the peak power; the cooling method of water cooling ensures the stability of the continuous operation of the laser cavity. It can be seen that this laser provides a stable UV light source for glass processing and marking.