RFH Green Laser Etching Conductive PET Film

Feb 10 , 2023RFH Green Laser Etching Conductive PET Film

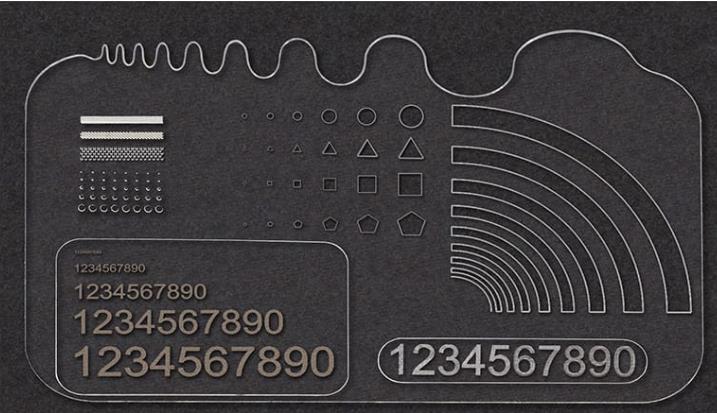

An example of RFH 10W 532nm green laser applied to fine laser etching of conductive materials on PET and other films. As we all know, laser etching is dry etching, and the processing process is simple, but this "simplicity" requires technical support, that is, the laser system with superior beam and its accessories. A superior laser, such as the solid-state laser forged by RFH for 12 years, is the basis for achieving a 99% yield rate for laser etching.

At present, ultraviolet lasers and green lasers are the main equipment used in the etching of conductive materials. Next, use a conductive thin film laser etching machine that uses RFH's 10W 532nm green laser to illustrate the importance of laser beam quality.

As we all know, laser etching is automatically controlled by the laser system. Therefore, as long as the quality of the laser beam remains stable, the processed products are consistent and meet the requirements. However, it is not only the laser that affects laser etching, but also factors such as power supplies, and the laser is one of the stable and controllable ones. For example, RFH's 532nm green laser has beam quality M2 <1.3 and pulse width <35ns@30k, which are strictly guaranteed in all frequency ranges, so its processing heat-affected zone is very small and guaranteed. The test data shows that the yield rate of this conductive thin film laser etching machine is 99%.

In addition to the stable quality of laser components, there is a one-to-one relationship between the power supply and the laser. The stability of the power supply control system determines whether the laser can maximize its performance during operation. RFH has the advantages of self-developed power supply technology, can update the functional modules of the power supply control system in time, and improve the functional modules according to the needs of lasers. 12 years of research and development technology accumulation, domestic and foreign professors, doctoral research and development teams, this is the solid backing for the stable operation of RFH's entire laser system. The compliance rate of RFH laser parameters is 100%. Finished product testing and pre-delivery re-inspection are part of RFH’s rigorous quality management system. Multiple tests ensure that the laser quality is stable and the equipment parameters are consistent with the actual operating parameters, ensuring the supply to customers. It is good quality. Because of this, we have won the trust of the vast market.

In addition, RFH's 355nm ultraviolet laser is also a standard laser for application and fine laser etching. About its application case, I will introduce it later.