The power adapter uses UV laser for coding, has little thermal influence

Apr 12 , 2021The power adapter uses UV laser for coding, has little thermal influence

The mobile phone needs to be charged, it must be connected to the charger. The quality of the charger will directly affect the personal safety of the user, so UV laser marking instead of ink jet coding machine marking is already very popular. UV marking does not fall off for a long time, preventing the appearance of fake and inferior products, and plays a good anti-counterfeiting effect. The mobile phone charger laser marking adopts "non-contact" processing, which will not cause any damage or deformation to the workpiece.

Seiko 13 years, deep cultivation of ingenuity

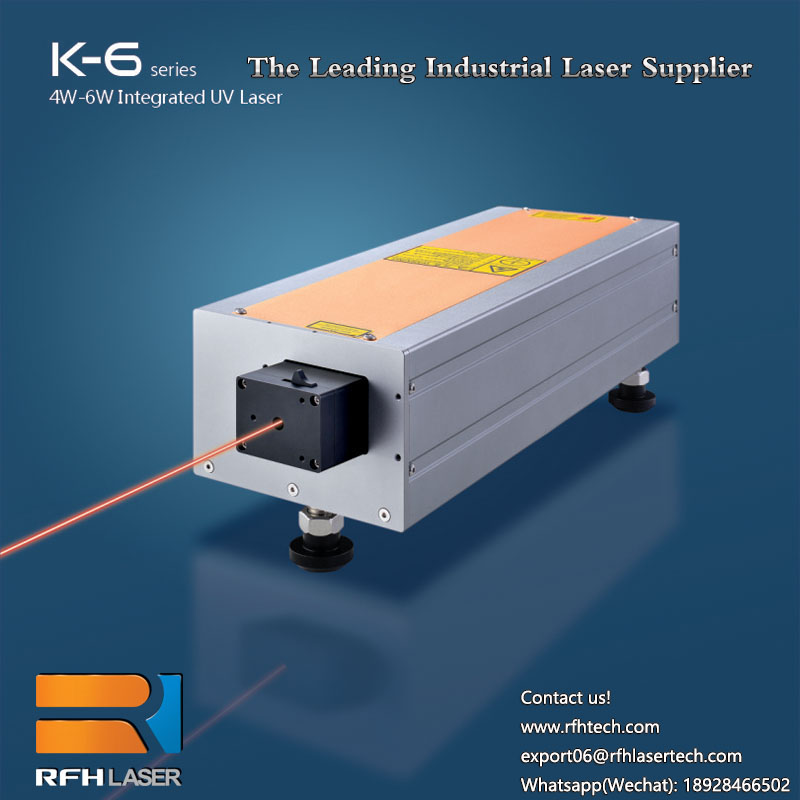

The global industrial-grade solid-state laser developed and produced by RFH completely solves the problem of fading and falling off of the date or batch number of the mobile phone charger through a non-contact and lossless marking method.

RFH UV laser has low thermal influence and fast marking speed

RFH research and development, each UV laser produced has superior beam quality (M2<1.2), perfect spot characteristics, and strict guarantees in all frequency ranges; and pulse width <12ns@30k, which can make the heat affected area during processing It is small, not easy to scorch, not deformed, and the marking effect is finer. In addition, the solid-state laser also has unique Q-switching control technology, which can be suitable for various laser application control needs; coupled with the internal cavity self-purification system function, the laser has a long life and stable operation. It adopts full digital display, supports communication with computer, and can remotely monitor lasers. The integrated compact design facilitates equipment integration. Such excellent technical advantages enable the product to maintain consistent stable quality, constant beam quality, and high-efficiency power consumption characteristics under extreme industrial and scientific research conditions.

The UV laser is produced in a dust-free workshop throughout the entire process, from procurement-pre-production quality inspection control-rigorous assembly process-finished product testing-warehousing quality inspection-pre-delivery inspection-after-sales service to ensure quality stability and equipment parameters. Consistency of actual operating parameters. This is the reason why the service life of RFH brand lasers is better than that of peers.

In addition, there is a one-to-one correspondence between the power supply and the laser, and the stability of the power supply control system determines whether the laser can maximize its performance during operation. RFH has the advantages of independent research and development of power supply technology, which can update the function modules of the power control system in time, and improve the function modules according to the needs of the laser. 13 years of R&D technology accumulation, domestic and foreign professors, doctoral level R&D team.

This is a solid backing for the stable operation of RFH's entire laser system.

What’s more worth mentioning is that from the user’s point of view, RFH has launched a complete laser system sales plan (power supply + laser head + cooling system) to ensure the stability of the entire laser system and achieve good performance. Users no longer need to worry about whether the cooling system selection matches. problem.