UV Nanosecond Laser Engraving Bar Code of Production Date of Food Packaging Bag

Apr 02 , 2021355nm nanosecond UV laser for high-speed coding coffee packaging bags

Each package of espresso will have a UV-marked date and bar code, which is convenient for plastic source and anti-counterfeiting.

The thermal influence of the ultraviolet laser on the processed object is negligible. When the heat-affected area is small, there will be no thermal effect, and there will be no deformation or scorching of the packaging bag due to the high energy of the laser beam. It happened.

Therefore, it is mostly used in food packaging bag printing logo, trademark, text, pattern, production date, shelf life, certificate of conformity, serial number, code, barcode, two-dimensional code, anti-counterfeiting code, characters and other identification information coding problems, with Fast marking speed, high efficiency, long continuous use time, high engraving accuracy, stable performance, good marking effect, long service life, maintenance-free, zero consumables, simple operation, etc.

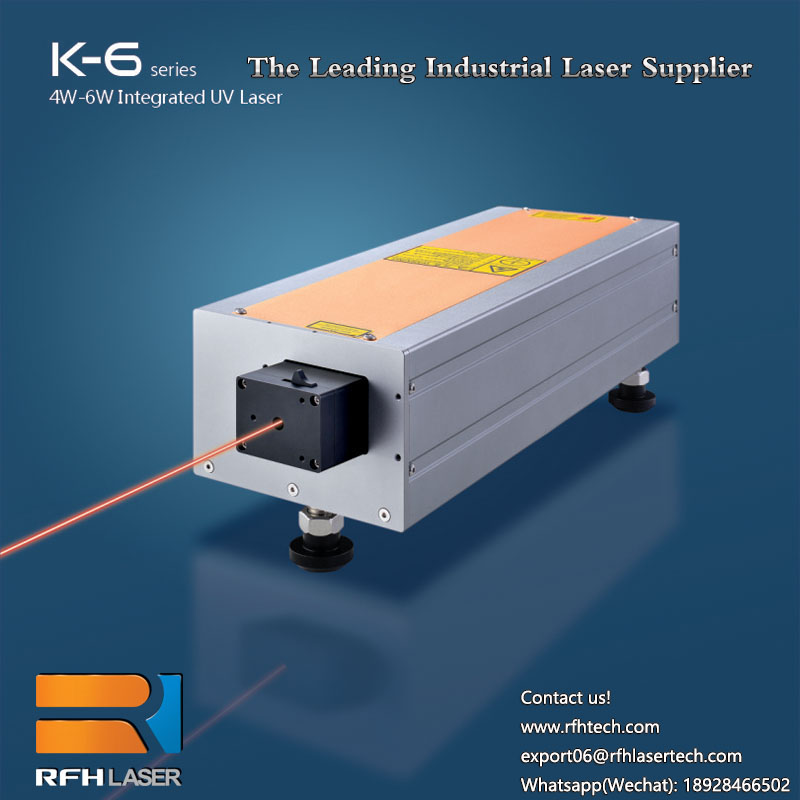

In the 13 years of Seiko, the RFH Expert Ⅱ 355nm UV laser has fully penetrated into the field of food packaging marking, such as the marking date of kitchen soy sauce plastic bottle caps, seasoning packaging bags, and mineral water bottle marking dates, etc., we can see everywhere in our lives.

RFH Expert Ⅱ 355nm UV laser has a wide range of repetition frequency (single pulse to 200kHz), can be absorbed by the material, and is less destructive to the material, sterile 0 pollution, the identification code does not fall off, the handwriting is clear and easy to identify, which is very suitable Mark high-density packaging.

At the same time, it has superior beam quality (M2<1.2), which is strictly guaranteed in all frequency ranges; pulse width <20ns@30k, the heat-affected area during processing is small, and it supports digital intelligent power control, simple operation, and low hands-on cost , To meet the rapid mass production needs of enterprises.

In terms of production, RFH has a rigorous quality management system mechanism, from purchasing-pre-production quality inspection control-rigorous assembly process-finished product testing-warehousing quality inspection-pre-delivery inspection-after-sales service, all levels of control to ensure stable quality And the equipment parameters are consistent with the actual operating parameters. This is the reason why the service life of RFH brand lasers is better than that of peers.

In addition, RFH has the advantages of independent research and development of laser power technology, which can update the power control system functional modules in time, and improve the functional modules according to laser requirements.

At present, RFH Laser has a global industrial laser research and development team composed of professors, experts, and doctors at home and abroad. At the same time, it has established an application process research and development department, a laser research and development department, and an electrical research and development department. This laser product can maintain consistent stable quality, constant beam quality, high-efficiency power consumption characteristics under extreme industrial and scientific research conditions, and win the trust of users from all walks of life with superior cost performance and high reliability.