355nm ultraviolet nanosecond laser has mastered the technology of engraving ceramic vases

Website: http://www.rfhtech.com

Whatsapp(Wechat): 18928466502

Email: export06@rfhlasertech.com

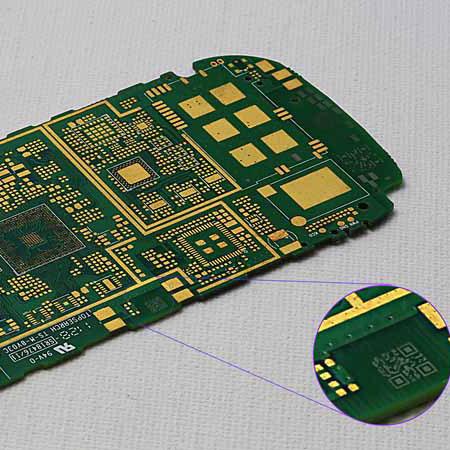

At present, the laser technology on the market has developed to a very advanced level. It can not only cut iron like mud - cutting all kinds of metal plates without any effort, but also can complete drilling, carving and other fine work in various fragile material suppliers. Only professional manufacturers who have mastered the laser technology can make the best use of the laser technology.

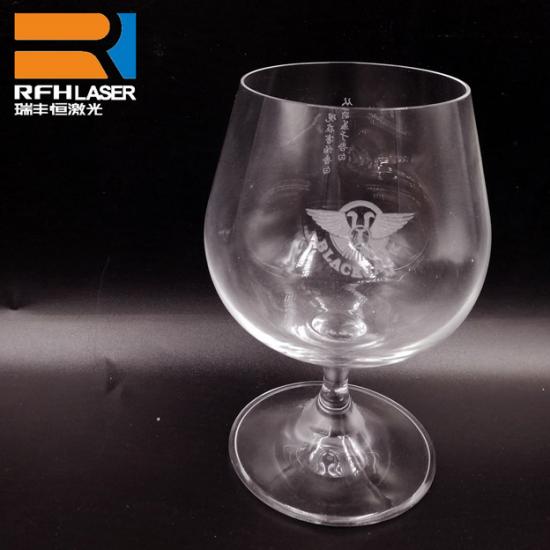

3W5W10W laser cold light source instead of traditional hand-carved ceramic vase technology

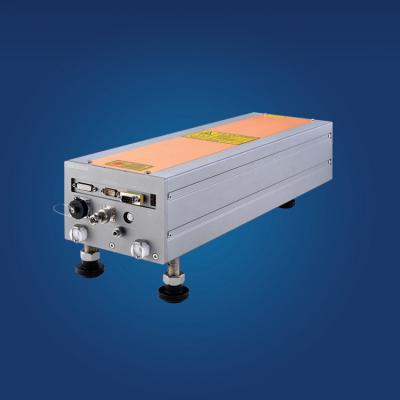

RFH has a high-power UV laser that can lightly mark fragile materials such as ceramics and glass. This high-power UV laser has excellent beam quality, and its accuracy and safety are strictly guaranteed in all frequency ranges. The pulse width is less than 20ns@30k, and the heat-affected area is small during processing, which can protect the product to the greatest extent. loss, and can easily complete the marking process.

RFH has a large number of cooperative customers in Jingdezhen. These customers choose RFH's high-power UV laser to mark their ceramic products. The ceramic production and processing factory where Mr. Gong is sitting is one of them.

RFH high power UV laser marking ceramic vases is very popular

Mr. Gong said that RFH's laser products are very popular among local ceramic manufacturers, and they all come to RFH to seek cooperation. RFH's ultraviolet laser adopts all-digital intelligent power control technology, which is easy to operate, easy to monitor, and supports communication with a computer. Any information that you want to mark on ceramic products can be easily displayed by entering the computer.

RFH Nanosecond UV Laser

After 15 years of development and precipitation, RFH Laser currently has an industrial-grade laser R&D team composed of professors, experts and doctors at home and abroad. It has established an application process R&D department, a laser R&D department, and an electrical R&D department. 10 national patent certificates, 14 items Computer software copyright certificate, won the "Guangdong Specialized New Enterprise", "High-tech Enterprise", "Shenzhen High-tech Enterprise", "Software Enterprise Certification" and other certificates, and was awarded by the Guangdong 3D Printing Industry Innovation Alliance and Guangdong The Provincial Laser Industry Association was appointed as the governing unit.

RFH laser development history:

In 2007, Shenzhen RFH Laser Technology Co., Ltd. was established;

In 2009, the RFH brand was recognized and familiar with the laser market in the 3D printing rapid prototyping industry, laying a solid foundation in the industry;

In 2014, the scale of the company was expanded, and the laser marking industry in the Pearl River Delta market, the Yangtze River Delta and other regions had a super high market share;

In 2015, it was awarded "High-tech Enterprise" and established offices in Wuhan and Suzhou;

In 2018, the domestic sales of RFH brand nanosecond lasers were leading, and the company entered a comprehensive systematic and modern enterprise management mode.

2020 New arrivals! S9 series UV laser, smaller size and stronger expansibility

In 2021, it won the title of "Guangdong Province Specialized New Enterprise" and "Guangdong Ultrafast Solid State Laser Engineering Technology Research Center". RFH will once again expand the plant area and production capacity, attract high-tech talents, and improve the after-sales service mechanism.

uv laser | green laser | Ultraviolet lasers | uv dpss laser | nanosecond laser | UV laser source | Solid State Lasers