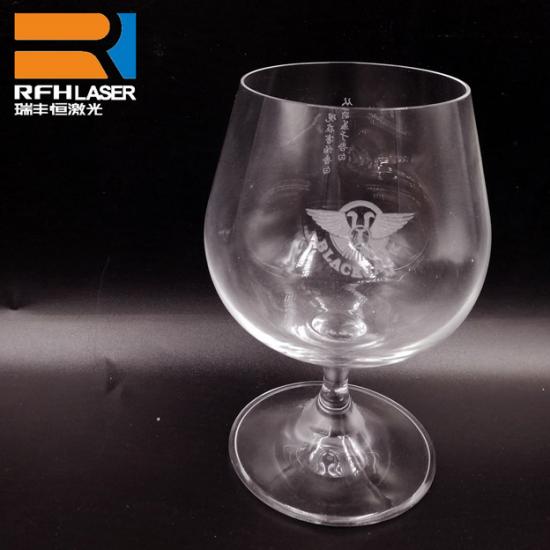

355nm UV laser frosted glass breaks traditional constraints and brings new technology impact

Website: http://www.rfhtech.com

Whatsapp(Wechat): 18928466502

Email: export06@rfhlasertech.com

I don't know if you have considered such a question, how is the frosted glass you see in daily life made?

The so-called frosted glass is also called "frosted glass" in many places, because the surface is very rough, so it will show a hazy translucent effect.

This kind of frosted glass is actually processed from ordinary glass. It is generally used in more private environments such as conference rooms and bathrooms. In addition to protecting privacy visually, it can also be further processed to play a sound insulation effect (soundproof glass). Mostly made of frosted glass).

The traditional way of processing frosted glass

Having said that, you can answer the first question, what is the traditional process of making frosted glass?

First of all, it needs to be clear that frosted glass is to make the flat surface of ordinary glass uneven, so that the light is scattered or diffused.

The most common way of traditionally processing frosted glass is to use "corundum" for grinding, which can be mechanically sprayed or hand-ground, and in this way, the entire glass can be processed.

Disadvantages of traditional processing methods

However, this processing method has many disadvantages. Here we can list the more common problems one by one:

1. The processing area is limited.

The area limitation mentioned here is not that it is not easy to process large areas, but on the contrary, it is that some delicate small-area processing cannot be done in traditional ways.

2. The processing fineness is not easy to control.

Since the processing of frosted glass is ground with "corundum", the processing skills of each master have a great influence on the final product. If the grinding is not uniform, the final product will not be uniform enough.

3. Cost of consumables and poor processing environment.

The most expensive consumables for processing frosted glass are emery and nozzles. These nozzles are made of ceramics, but they cannot withstand the ejection of emery. If large-scale processing requires frequent replacement of consumables. In addition, when processing frosted glass, the whole processing environment will be very harsh due to the corundum and dust in the sky, and workers need to take very strict protective measures.

The above points are only part of the drawbacks of traditional processing of frosted glass. It is precisely because of these shortcomings that people start to look for new ways to replace them. RFH laser is a more modern, environmentally friendly and efficient way.

To machine frosted glass with a laser:

Now that we know that to turn ordinary glass into frosted glass, the fundamental purpose is to roughen the surface of the glass, which can be easily done with a laser.

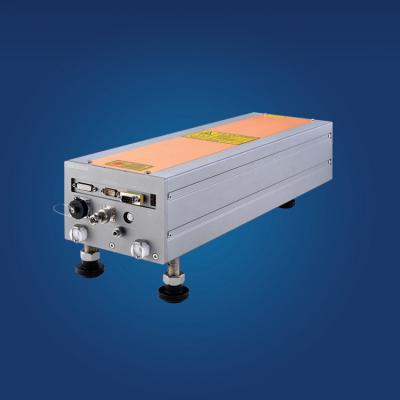

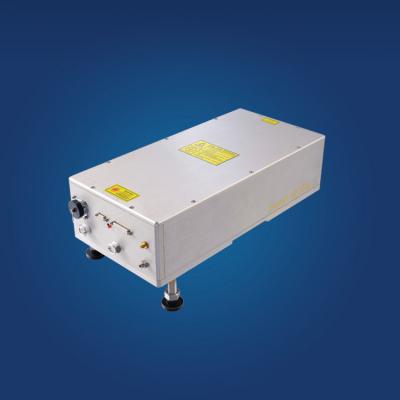

Frosted glass can be easily made with RFH's newest S9 series UV lasers, with great advantages.

1. Non-contact processing method, very environmentally friendly

Laser processing can minimize excess dust and purify the working environment, which is very environmentally friendly.

2. The machining accuracy is controllable

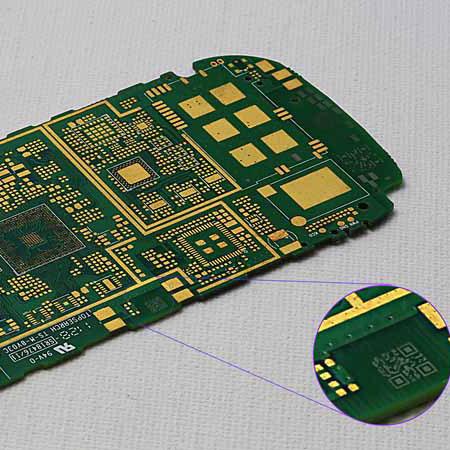

RFH S9 series UV lasers have very high beam quality (M²<1.2), and the heat affected area during processing is very small, making the processing fineness of glass truly controllable.

3. The advantages of processing fine products are obvious

When using the RFH S9 series UV laser for processing, the processing accuracy can be maintained at ±0.02mm, and even very fine items can be perfectly processed for frosted glass.

4. Small size and low maintenance cost

Since the RFH S9 series UV laser is the latest product, it is smaller in volume control than similar products, which also means that users do not need to make a large optical path, which can greatly reduce the cost, and the later maintenance is also very simple.

5. Fully digital display, can communicate with computer

In order to ensure the needs of modern processing, digitization is the general trend, RFH S9 series UV lasers have realized full digital display, and the parameters can be precisely adjusted through the computer, which meets the needs of modern processing.

The team of professors at home and abroad carefully crafted the S9 UV laser to easily make frosted glass

The above are some of the advantages of RFH laser processing. On this basis, RFH laser has a dedicated power control system independently developed, and a strong team of professors at home and abroad as technical support, with strong technical strength.

After years of technical accumulation, RFH laser has achieved today's achievements. The accumulation of independent technology and a strong technical team are the solid backing and the foundation for the stable operation of RFH laser.

uv laser | green laser | Ultraviolet lasers | uv dpss laser | nanosecond laser | UV laser source | Solid State Lasers