355nm UV laser high-precision laser engraving car keys

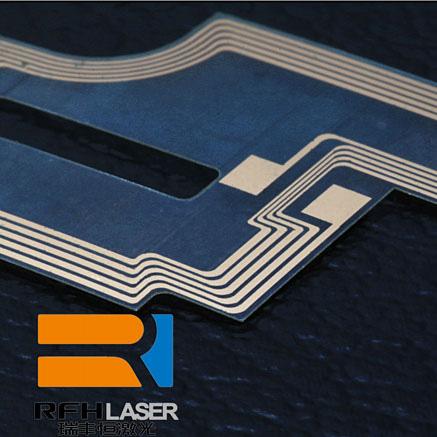

The rapid development of the automobile industry has made automobile parts have higher requirements in terms of design and aesthetics. For example, in the laser engraving of automobile buttons, RFH's ultraviolet laser provides a very valuable technology.

Application technology of nanosecond ultraviolet laser in laser engraving of automobile buttons

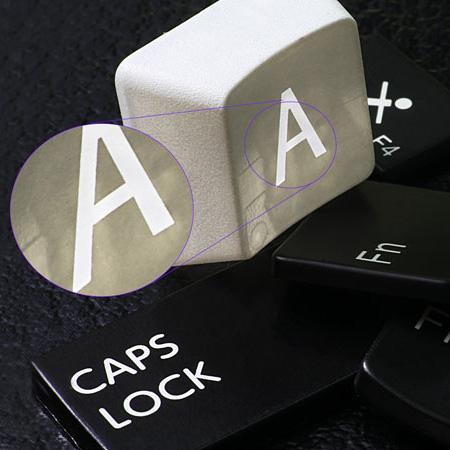

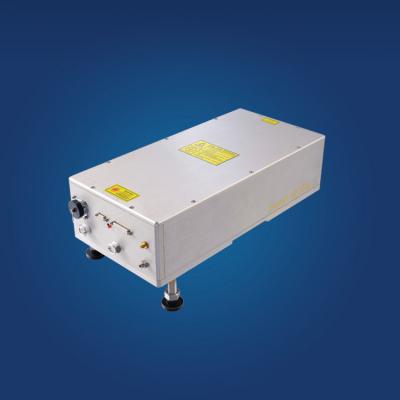

At a recent auto parts production exposition, RFH's exhibition area was crowded with people, and everyone was waiting to see how the UV laser, a laser device with such a small footprint, works. I saw that the RFH ultraviolet laser emitted a very small spot, which quickly swept across the surface of the material, leaving white marking marks. The entire laser engraving process of the button only took more than one minute.

It turns out that the car button indicator is made with an RFH ultraviolet laser.

The finished button product was uploaded and read by the onlookers. Everyone was surprised to find that the product marked by the UV laser could not be erased with fingers, even if it was dug with a nail button, it would not wear out. It has an absolute advantage in durability. . Secondly, the buttons produced by UV laser marking do not require consumables, and the marking can be turned on just by plugging in the electricity, which does not cause any harm to the environment and the health of the production personnel. In addition, the UV laser can run continuously for 24 hours, with high processing efficiency, low operating cost and no special maintenance.

RFH UV laser

Whether in terms of quality, speed, stability or energy conservation and environmental protection, UV lasers are currently the leader in the laser marking market. As a company aiming to become a domestic high-end laser technology company, RFH exhibited more than just The product is determination and perseverance not to forget the original intention.