355nm UV Nanosecond Laser Source Marking Cosmetic Labels

Aug 15 , 2022355nm UV Nanosecond Laser Marking Cosmetic Labels

On May 1, 2022, the "Administrative Measures for Cosmetics Labeling" was officially implemented, which means that cosmetics applying for registration or filing must comply with the provisions and requirements of the "Measures". Among them, Article 5 of the "Measures" stipulates that the minimum sales unit of cosmetics should have a label, and the cosmetic label should be clear, durable, easy to identify and read, and there should be no phenomenon such as falling off or not sticking firmly. At the same time, Article 7 also stipulates that the Chinese label of cosmetics should at least include the name, registration number, implementation standard number, registrant's address, company name and address, full ingredients, net content, use period, method of use, warning and safety use and other information. .

It can be seen that for cosmetics, the significance of labels is not unimportant, and the requirements for cosmetic labels are refined. In addition to further ensuring that consumers can obtain information about the safe use of cosmetics in an objective, clear and accurate manner, it can also be used to combat falsehoods. Expand publicity and other illegal activities.

In the past, the conventional methods of marking the production date, serial number, ingredients, etc. of cosmetics mainly include ink jet printers, labeling, etc., but these traditional markings tend to become blurred and fall off over time, and are very easy to be tampered with, resulting in Consumer rights are harmed.

The laser marking process can well meet the label requirements of the "Cosmetic Label Management Measures" by virtue of the advantages of permanent, clear, non-shedding, and non-tampering.

For different materials of cosmetic packaging, when the 355nm ultraviolet nanosecond laser of Nafei Optoelectronics is used for laser marking, it does not choose the material material. This is due to the high single-photon energy of 355nm ultraviolet light and the high absorption rate of materials, especially the commonly used cosmetic packaging. Plastics, films and other heat-sensitive materials, the cold processing properties of 355nm ultraviolet light, and the pulse width of the laser about 25ns, the thermal effect is low, and the carbonization, scorching, melting, etc. caused by high-energy density laser beams are well avoided. The content is not limited to the text, symbols, numbers, patterns and other signs of product basic information, attribute characteristics and safety warnings.

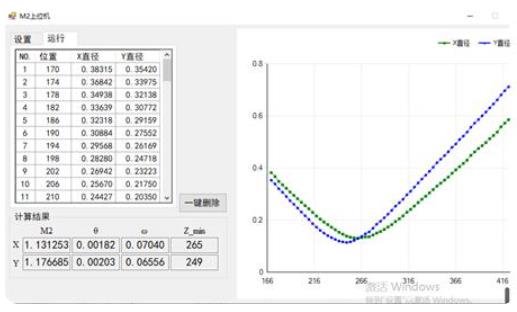

Moreover, the beam quality of the 355nm UV nanosecond laser is excellent (M2<1.2), and the 355nm UV light is easy to focus. When marking on cosmetic packaging, the beam is particularly fine, at the micron level, which enables high-contrast, high-resolution lasers The size of the mark and the marked graphic information can be large or small, simple or complex. By integrating in the production line, one product can be one code, effectively eliminating counterfeit and shoddy products, and protecting the economic and brand interests of cosmetic manufacturers.