3W5W10W UV laser cutting glass lamination cutting edge is not black

Website: http://www.rfhtech.com

Whatsapp(Wechat): 18928466502

Email: export06@rfhlasertech.com

The status of glass in modern industry is unquestionable, and the glass processing technology is also becoming more and more sophisticated. Some coating technologies can provide glass with more functions, such as anti-blue light, anti-ultraviolet, or anti-peeping.

The most common coated glass in life is mobile phone screen and car glass. These coated glass have characteristics that traditional glass does not have.

The New Favorite of Glass Laminate Cutting: RFH 355nm UV Nanosecond Laser

Human research and innovation on glass has never stopped, and it is precisely because of the heavy dependence of modern industry on glass, and even "glass science" has appeared in the field of applied science, which is enough to see how great the changes that glass coating has brought to the industry.

What is glass coating?

Glass coating is so important, then we need to know how to coat glass.

As a very important process in glass production, glass lamination is to cover some adhesive films with specific functions on the glass surface. At this time, a "glass lamination machine" is needed.

▼Glass Laminating Machine

Although the glass film in industrial production is not much different in essence from the film on the mobile phone, the precision of the film produced in industrial production is much higher than that of the daily film.

More importantly, the process of glass lamination requires a process of cutting glass lamination. The traditional glass lamination cutting is done by pulling film cutting equipment. This cutting technology is very inefficient, and the efficiency of laser cutting lamination is far more efficient. Higher than the film cutting technology.

RFH laser perfectly cuts glass laminates:

The use of laser to cut glass film is not only efficient, but also cost-saving, with dual advantages, and has now become the new darling of industrial production.

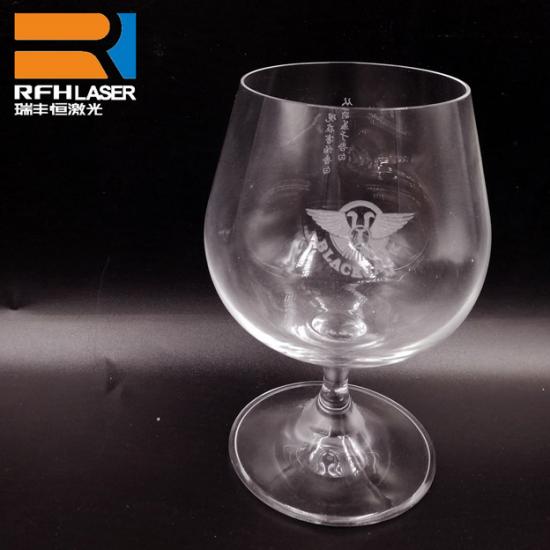

▼RFH laser cutting glass coating

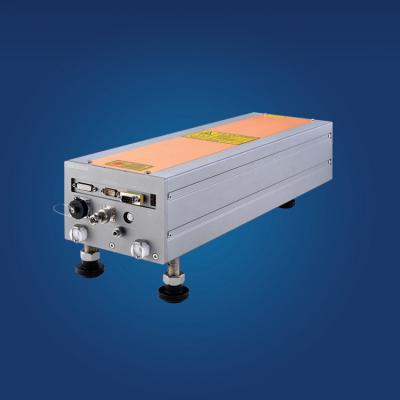

RFH S9 series lasers have precise power consumption control and extremely high precision, and can achieve one-time, precise and fast cutting when cutting glass laminations.

One cut:

When using traditional film-drawing cutting equipment, the glass film can only be cut horizontally, which results in at least two cuts for each film processing, which can no longer meet the high-efficiency requirements of modern industrial production.

The RFH S9 series laser is used to process the lamination in one step. Through complete digital control and remote computer parameter adjustment, it can meet the one-time cutting of pattern and size.

Precise cut:

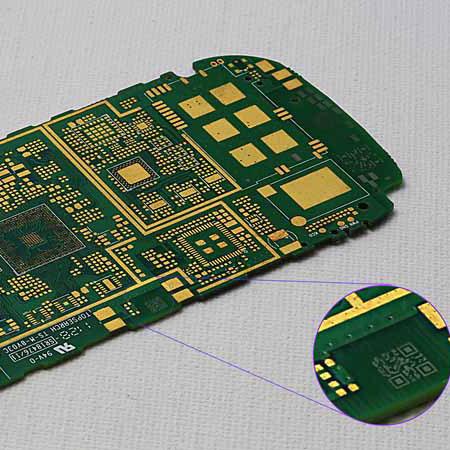

RFH S9 series lasers have ultra-high cutting accuracy of ±0.02mm, and it is no longer a problem to deal with meticulous processing requirements. More importantly, the precise control of power consumption by RFH S9 series lasers can make the cutting edge not black when cutting glass coating, which is impossible with traditional processing technology.

Quick cut:

While satisfying higher-precision cutting, RFH S9 series lasers can complete the cutting work faster. The non-contact processing method of laser can be used properly, which can leave a large amount of expenses for enterprises.

In addition to the above features, the small size and highly integrated industrial design of RFH S9 series lasers are also huge advantages. The compact size saves space and saves the processing cost in disguise.

One-time cutting and forming, RFH 10w UV laser has no doubts in glass cutting

Because of the high degree of integration, the installation is very simple, saving space and time, and it can be used immediately without making a large optical path, which is also a huge advantage.

Because of RFH's continuous breakthroughs in the laser field and 15 years of unremitting research and development, today's laser technology is very mature. RFH, supported by a number of patents, has a strong technical team support and has a leading position in the industry.

Years of hard work and constantly upgraded technology have not become RFH's love for the industry, and have taken a step within its capabilities for the popularization of laser technology, steadily and steadily, to provide enterprises with efficient solutions.

uv laser | green laser | Ultraviolet lasers | uv dpss laser | nanosecond laser | UV laser source | Solid State Lasers