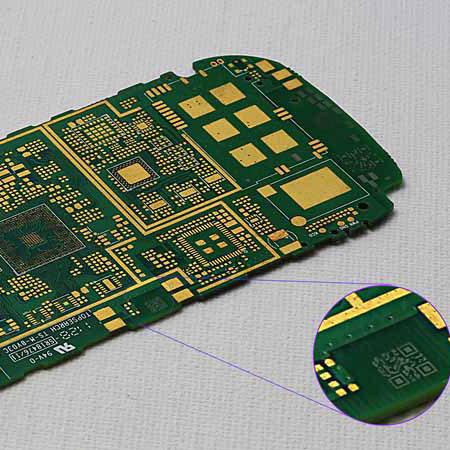

Nanosecond UV laser marking plastic QR code, clear bar code pattern, sharp font

Website: http://www.rfhtech.com

Whatsapp(Wechat): 18928466502

Email: export06@rfhlasertech.com

I believe that everyone is familiar with laser marking. 3C products and outer packaging will have many uses for laser marking.

In this era, the demand for 3C products is rising, and the product identification is becoming more and more clear. The use of laser marking is not only fast, but also processing without consumables, which greatly reduces the cost.

For such precise plastic marking on the fly, the RFH 355nm ultraviolet laser is not allowed

As the precision requirements of machined parts increase, precision marking as small as the charging head has also brought great challenges to the laser industry, but the precision processing can hardly fail RFH, which has been deeply cultivated in this industry for 15 years.

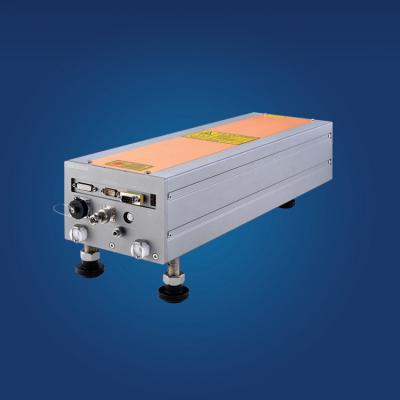

With the accumulation of powerful technology, the RFH S9 series lasers have reduced the spot diameter to the micron level, and no matter how precise the marking work is, it can be easily completed.

Two-dimensional codes, barcodes, and product logos can all achieve clear patterns and sharp fonts.

RFH has completely overcome the challenge of marking accuracy. Under the requirements of industrialization, it has always been mass production, and automatic marking has naturally become the general trend.

On the basis of high-precision marking, RFH has completed the automation of "plastic flying marking". Even small parts can be marked automatically in large quantities, which improves industrial production efficiency.

RFH Plastic Flying Marking Application Video

To achieve such a precise flying marking, the RFH S9 series does its part and solves three major problems:

Full CNC, precise control of marking accuracy

In the face of "plastic flying marking", precision control is the most important thing. If one parameter is not properly controlled, it will be easy to fly and be crooked. To achieve a completely consistent high-quality marking, full numerical control is the most important thing.

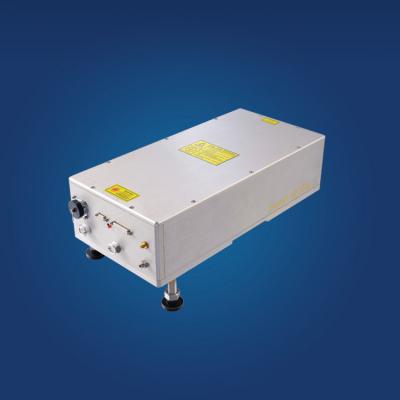

RFH adopts a fully digital operation panel, and communicates and controls precision through a computer, and each parameter can be adjusted in detail. This all-digital approach not only makes the accuracy easier to control, but also more intuitive, and the integration of the equipment is also higher.

Of course, to achieve a fully digital display operation panel, not only the support of high-precision hardware is required, but also a strong software research and development capability, which combines software and hardware. The RFH S9 series does it.

RFH S9 series laser full digital control interface

Small size, no need to make a large optical path, saving cost

RFH S9 series lasers not only achieve high precision, but also through highly integrated industrial design, the volume of the laser is very small, which not only saves space, but also does not need to make a large optical path, and the installation is naturally very fast.

Through the highly integrated industrial design, the volume can be reduced while the investment cost is reduced, and the cost-effective characteristics of laser marking can be maximized.

RFH S9 series laser

Excellent power supply design, stable power control

The last thing to talk about is the stability of laser marking. Plastic marking is mostly black plastic white or white plastic black. The depth of the color is controlled by the power and defocus, and the power is controlled by the power supply design.

There will be many uses for UV laser marking on 3C electronics and outer packaging.

The power stability of a laser largely depends on the power supply design. RFH S9 series lasers have a power supply design higher than the industry standard, featuring stable power and long service life.

Under a wide range of laser applications, the high quality and stability of the RFH S9 series will definitely shine. It will not only be widely used in the 3C industry, but also large-scale "flying marking" applications will be used in various outer packaging.

RFH has been researching and developing in the laser field for 15 years. It not only has mature technology, but also has a number of patents. A strong technical support team is also an industry benchmark, which can provide complete technical support and contribute to the popularization of lasers.

uv laser | green laser | Ultraviolet lasers | uv dpss laser | nanosecond laser | UV laser source | Solid State Lasers