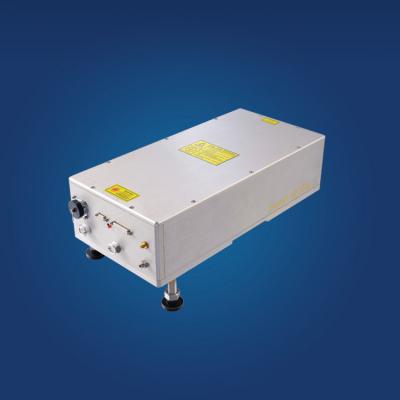

RFH UV laser peels paint on PET material, translucent and no lines

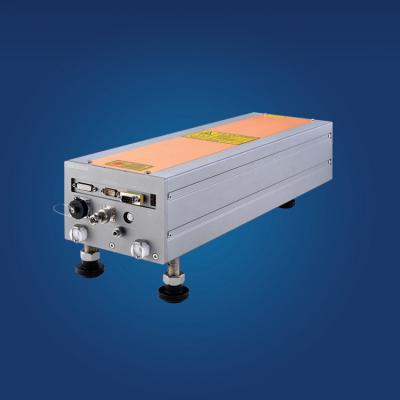

The problem of peeling PET plastic paint is the 355nm UV laser

PET materials are used in many fields such as wine bottle bases, water cup handles, glasses, plastic films, etc. It can be said that the ways of use are quite wide, and when using different PET substrates means changes in paint, how to make PET plastic spray paint Is the lacquer problem solved? After years of trying, RFH handed in a good answer.

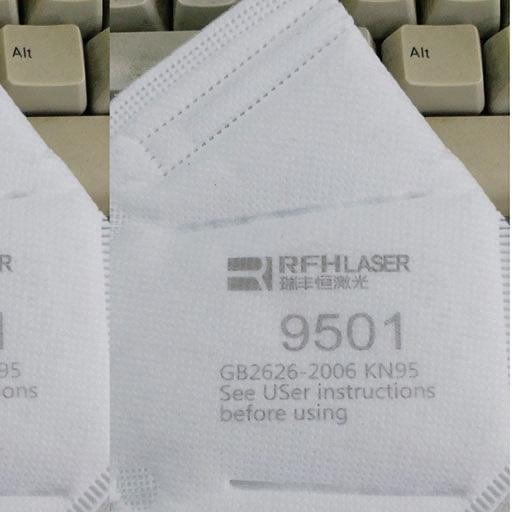

RFH UV laser can peel paint on PET plastic surface

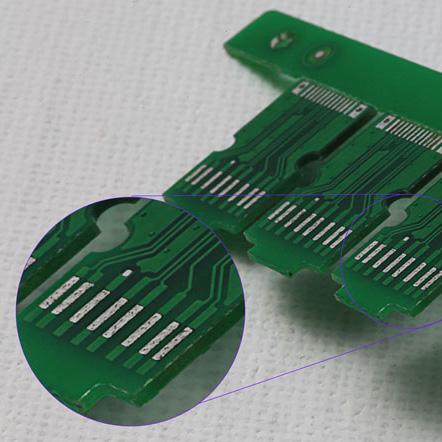

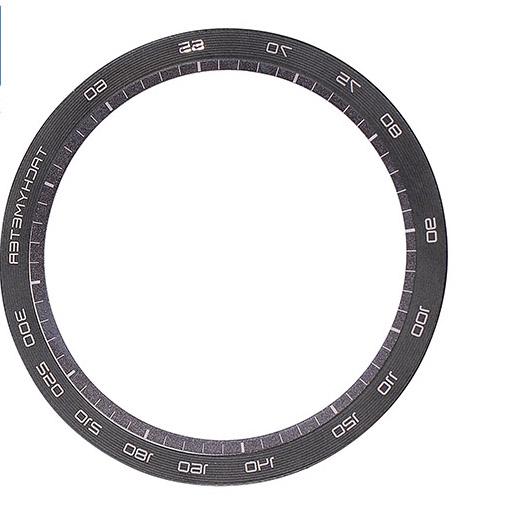

RFH UV laser can peel paint on the surface of PET plastic. During operation, RFH can peel paint accurately after PET is properly treated. As a plastic material, PET is susceptible to deformation due to high temperature. Therefore, RFH uses a very small UV spot to strip the paint, which does not produce thermal effects, has a small heat-affected area, and can easily solve the problem of material loss.

RFH provides customers with free lifetime technical support

In addition, the paint peeling problem that most manufacturers worry about in production no longer exists. The work and strength of RFH's very small spot on the surface of the material can ensure the exquisite peeling process and avoid the peeling process. It can be said to have the best of both worlds. Ultra-fast, low-carbon and energy-saving UV lasers are suitable for assembly lines, which are quite suitable for small PET products. Moreover, RFH also provides customers with free lifetime technical support, without the need to invest more in professionals What about the cost?

RFH's persistent spirit keeps UV lasers on the road of PET peeling

RFH has been committed to solving the problems of marking and peeling paint of various materials for many years, and always accepts all the suggestions and opinions put forward to customers. It is good at finding reasons from technology, research and development, and testing. It is such a persistent spirit that has made the RFH that continues to advance today.