Singapore customers purchase RFH UV nanosecond laser marking bulbs for traceability and anti-counterfeiting

Website: http://www.rfhtech.com

Whatsapp(Wechat): 18928466502

Email: export06@rfhlasertech.com

Ultraviolet laser is a non-contact marking technology. Compared with the past technology, it has a great improvement. It completely avoids the defects of the past technology in principle and use, and reaches a very good level.

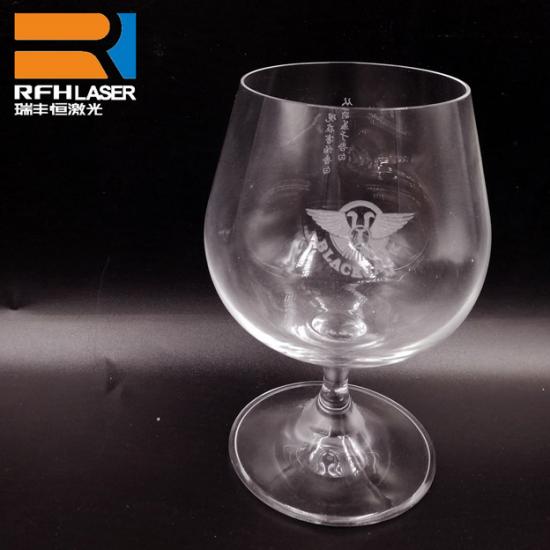

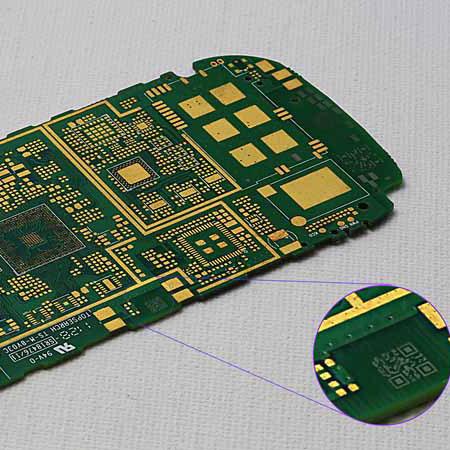

A customer from Singapore recently ordered an ultraviolet laser at RFH to mark the bulbs produced. The difference between the RFH UV laser and the traditional inkjet printer is that it uses a light spot for non-contact marking. The combination of low temperature and cold light source enables the part of the material surface that needs to be marked to be imprinted and never worn out.

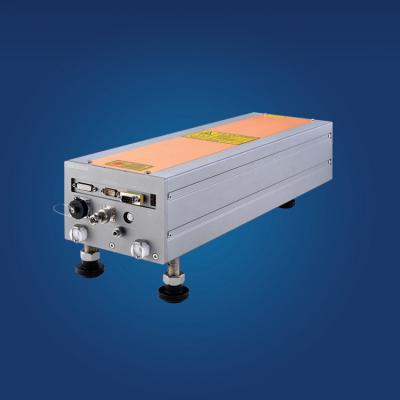

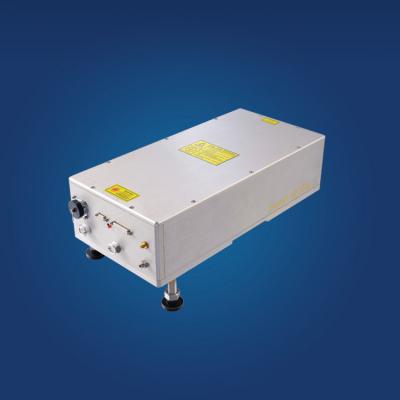

RFH 3W5W10W UV laser laser cold processing technology allows Singapore to place orders quickly

The RFH UV laser can be operated only by plugging in, and there is no need to add extra materials such as ink during use, and it can be operated continuously for 24 hours without being supervised by a dedicated person. It is a very convenient technology to use.

In addition, the UV laser will not produce pollution and dust during the use process. It is a truly environmentally friendly technology. The marking effect is very good. It can accurately reflect the content on the surface of the material, and it will not dissipate after repeated friction. Marking the traceability information of the bulbs has played an important anti-counterfeiting effect on the assembly line of Singapore customers.

Small body is great! RFH UV laser 0 add marking bulb plastic parts

It is worth mentioning that RFH has the advantages of independent research and development of power supply technology, which can update the function modules of the power control system in time, and improve the function modules according to the needs of the laser.

RFH 355nm uv laser

Singaporean customers are very satisfied with the RFH ultraviolet laser and are full of expectations for this new technology. RFH has opened up the international market through more than ten years of hard work and will deliver the independently developed technology to all parts of the world in the future.

uv laser | green laser | Ultraviolet lasers | uv dpss laser | nanosecond laser | UV laser source | Solid State Lasers