UV laser is the best source for marking PVC plastic

Compared with traditional marking technology, the application of laser marking on plastic products has the characteristics of high temperature resistance, strong light resistance, corrosion resistance, water resistance, and scratch resistance. More importantly, laser marking can ensure that the material itself is not damaged or damaged to a large extent, and the operation is more convenient, and the process is more environmentally friendly.

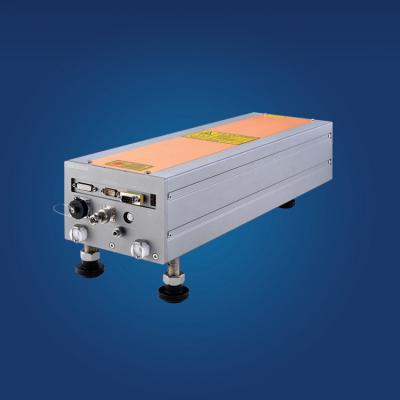

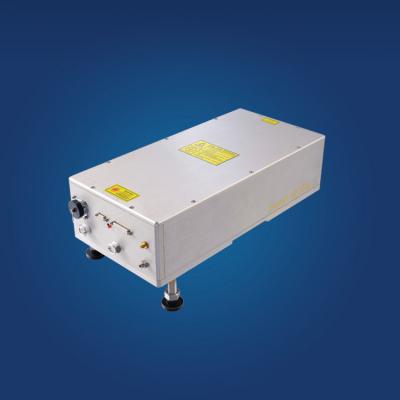

RFH Laser has done a lot of research and exploration on the marking of plastic products. The S9 series products of RFH Laser have excellent performance in plastic marking. The following is the marking application of RFH Laser on plastics.

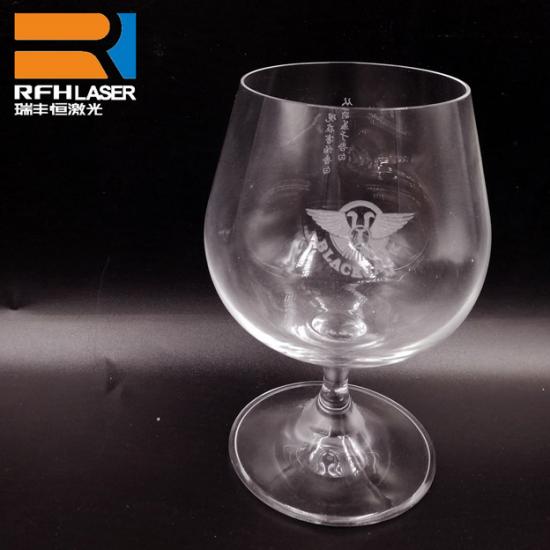

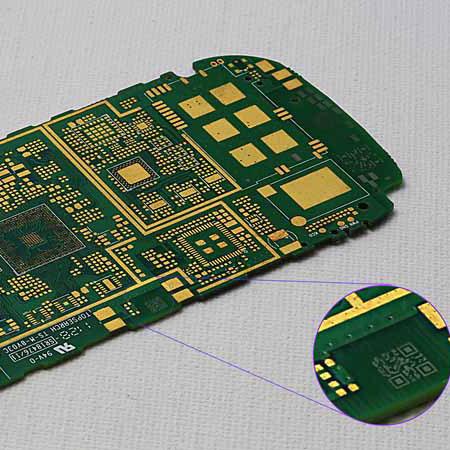

RFH S9 series ultraviolet laser can perfectly mark the serial number, product production date, product copy, LOGO, barcode, QR code and other elements on plastic products. Its marking effect has the characteristics of fast speed, high efficiency and clear imaging. , There will be no distortion, black fonts, and blurry patterns. At the same time, due to its excellent beam quality and higher pulse frequency, RFH S9 series lasers can make the laser marking of plastic products more stable, showing the marking effect of uniform lines, strong contrast and fine patterns.

uv laser | green laser | Ultraviolet lasers | uv dpss laser | nanosecond laser | UV laser source | Solid State Lasers