Latest Blog

High-repetition frequency, nanosecond green laser enables high-quality, rapid glass processing

Oct 13 , 2023

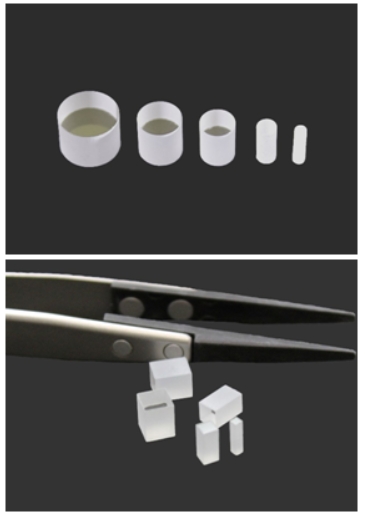

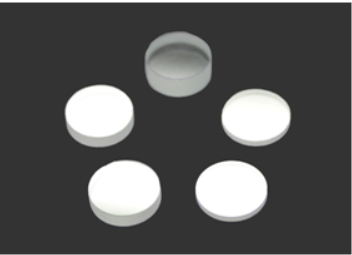

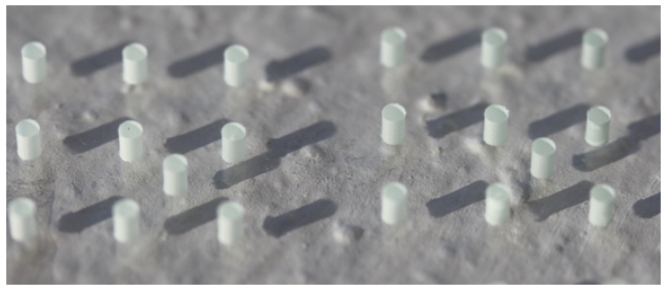

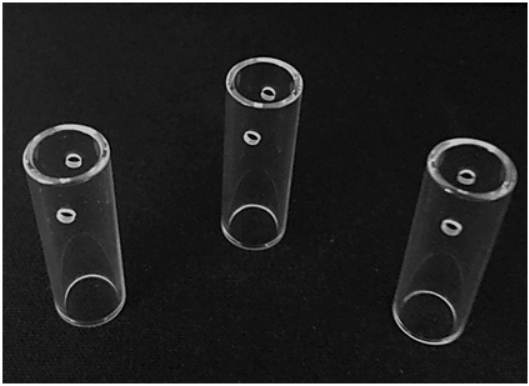

The glass laser drilling equipment uses a high repetition frequency 532 nm nanosecond green laser, combined with laser back processing (that is, the beam focus moves from bottom to top) process, which can perform various types of thin glass and tubular glass of various materials. Fast finishing. For example, drilling holes along the end face or side wall, cutting special-sized glass sheets, removing the transparent conductive film on the glass substrate, local texturing and scoring of the glass surface, marking on the surface or inside, etc. Depending on the pulse width and pulse repetition frequency, the maximum average laser output power can reach 50 W. As far as glass drilling is concerned, the hole diameter can usually be as small as 0.15 mm and as large as 50 mm or more, which can produce nearly zero-taper through holes, blind holes, oblique holes, step holes, square holes or other special hole shapes. . Tucson Laser uses high repetition frequency nanosecond green fiber laser to process soda-lime glass, borosilicate glass, quartz glass, etc. It has many successful cases in the field of glass deep processing. The applicable glass thickness range is usually 0.1 mm - 10 mm. between. Switching to 0.5 mm thick soda-lime glass, the maximum wire cutting speed can reach more than 22 mm/s. Figures 1 to 3 respectively give some representative pictures of glass processing results.

5.8 mm thick soda-lime glass

Borosilicate glass of different thicknesses

0.17 mm thick soda-lime glass

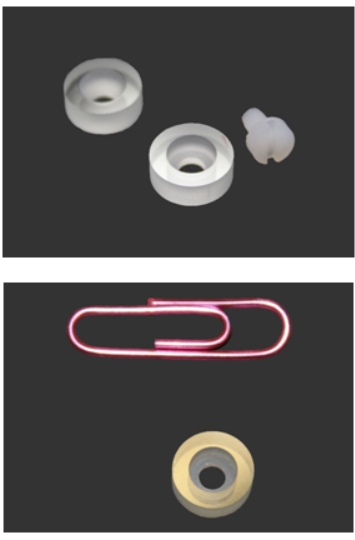

figure 1. Some glass samples cut by Tucson Laser using a high repetition frequency nanosecond green laser.

figure 2. Tucson Laser uses a high repetition frequency nanosecond green laser to drill a 1 mm diameter hole in a float glass plate with a thickness of 3 mm. (The time it takes to drill each hole is less than 1 second, and the edge chipping is less than 130 um).

image 3. Tucson Laser uses a high repetition frequency nanosecond green fiber laser to drill a 2.0 mm diameter hole on the side wall of a glass tube with a wall thickness of 1.0 mm.

Different from CO2 laser glass surface scribing and heating lobes and ultra-short pulse laser glass internal filament lobes, the use of high repetition frequency nanosecond green fiber laser to achieve glass cutting is mainly based on the point-by-point ablation of the workpiece by a single laser pulse and the laser focus. A rapid scanning movement through space following a predetermined design path. Therefore, it is more flexible and can perform highly controllable material removal point by point, line by line and layer by layer on various glass materials, so it can be regarded as an efficient "digital" with high precision. Laser glass cutting processing technology. This technology makes it possible to use lasers to cut different three-dimensional shapes or three-dimensional topography on various glass materials. This point-by-point cutting laser glass processing technology usually has a certain cutting line width and irregular chipping at the cutting edge. Depending on the thickness of the glass, the specific processing dimensions, and the cutting speed requirements, the cutting line width in actual applications is usually between 0.1 mm and 0.45 mm, and the maximum edge chipping can often be controlled within 100 um and 150 um. Under special circumstances, such as ultra-thin glass and relatively small processing size, the maximum edge chipping can be controlled between 50 um and 80 um. Figure 4 shows the tapered holes and step holes processed using high repetition frequency, nanosecond fiber green light laser, and Figure 5 shows the scribing and grooves on the surface of soda-lime glass. The scribing width is about 5 um, and the scribing speed is 3000 mm/s; the depth of the rectangular groove can be from a few microns to hundreds of microns, or even millimeters, and the depth control is not only accurate but also simple and convenient.

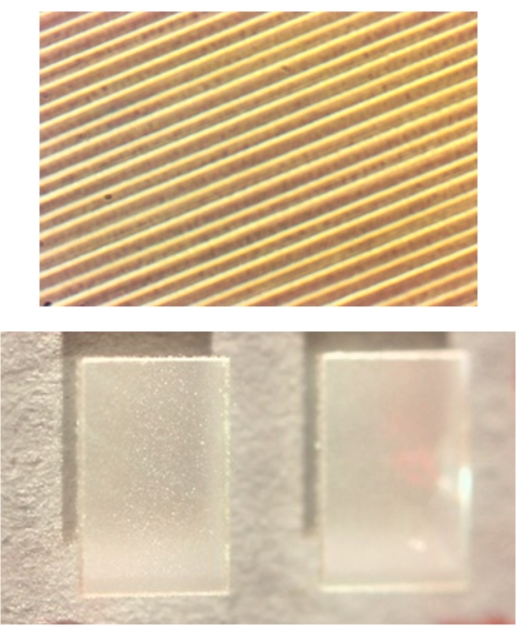

Figure 4. Tucson Laser uses high repetition frequency nanosecond green fiber laser to process tapered holes and step holes.

Figure 5. Tucson Laser uses a high repetition frequency nanosecond green fiber laser to produce scribing lines on the glass surface (left picture) (line width is about 5 um, scribing speed 3000 mm/s); 4.5 mm X 3 mm rectangular groove ( Right picture), the groove depth is 20 um to 200 um.

It is worth pointing out that the ablation mechanism of high repetition frequency, nanosecond green laser pulses on glass materials is not the conventional thermal melting of the material and then being discharged or vaporized by the auxiliary gas, but mainly stems from the local thermal stress gradient induced by the laser pulse. The resulting material collapse within a limited space. According to estimates, under typical circumstances, the average amount of glass material removed by one laser pulse in such processing is only about tens of nanograms or less, and the corresponding glass particles are about 20 to 30 microns to several microns in size. This unique method of material ablation and removal has significantly higher cutting efficiency than corresponding material thermal melting and gasification. Taking ordinary soda-lime glass as an example, its material removal per unit light pulse energy can reach 150 um3/uJ. The roughness of the cut wall is typically on the order of a few microns. When using high repetition frequency nanosecond green light fiber laser to ablate glass, in addition to promptly inhaling the dust generated during cutting into a vacuum cleaner, other auxiliary means such as air blowing or pressure are generally not required.