Latest Blog

The differences between laser marking, laser engraving & laser etching

Nov 01 , 2022What are the differences between laser marking, laser engraving and laser etching? We simply explain how each of these methods work, the differences, which materials are suitable and what are the typical applications.

The laser beam is a universal tool that can work such different materials like wood, glass, stone, paper, plastics and more. Tools like laser marking, laser engraving, and laser etching have become widely spread over the last decade or so due to governmental regulations calling for clearly readable product and part identification. However, the capabilities of laser marking, laser engraving and laser etching have also found their way into the toolbox of the make community, making customizations possible that would take an artisan with traditional methods.

But what are the differences between laser marking, laser engraving and, laser etching? Do you need different machines to process your parts with these methods, or are there machines that are capable to them all?

What materials are suitable to which process? How can I start laser marking, laser engraving, and laser etching at home?

Read to learn the answers to these questions concerning laser marking, laser engraving, and laser etching will be answered.

Laser Marking

Image of Laser Marking , Laser Engraving & Laser Etching – The Differences: Laser Marking

How does Laser Marking work?

This process works by sending out a low-powered beam onto the surface of the workpiece causing the material under the surface to oxidize. In other words, the laser beam turns the material black. The result is a high-contrast image that is both permanent and very resistant. For this reason, this method is sometimes also known under other terms like “laser coloration” or “laser dark marking”.

What are the Differences to Laser Engraving & Laser Etching?

Unlike laser engraving and laser etching, this method does not disrupt surface. Meaning no material is removed from the part and the surface retains its texture.

Both laser marking and laser etching can be used to add logos and text to parts. The difference is that the oxidized material of laser marking turns black, while laser etching alters the reflectivity and the contrast with the surrounding material. Hence, laser etching is the preferred method for objects made from precious metals.

This variety of laser technology is the least common featured in this article. It is mostly used by medical and automotive companies. Therefore, not every service will offer laser marking.

Can I do Laser Marking at home?

Yes, you can! Laser marking is supported by most commercially available laser machines. The deciding factor that determines the operating mode is the intensity of the laser beam.

If you don’t want to spend money on a desktop laser marker, or just have one project to undertake, you can utilize an online laser processing service. There is a wide range of manufacturing services that offer laser marking, laser engraving, and laser etching. The most poular among these are probably Ponoko and Sculpteo.

What are typical applications of Laser Marking?

Laser marking can be applied to a large variety of materials. You can use it not only on flat parts, but also on surfaces that are curved or even round.

Companies in the medical device industry or automotive fields are used this technology as a means to trace bespoke parts in their processing facilities. To this end, they laser mark serial numbers or model codes onto their products’ surfaces.

However, laser marking is less commonly used by hobbyists who often prefer laser etching.

How does Laser Marking compare to traditional techniques?

Laser marked parts may look like they have been printed on, but this technology is superior to tradition printing or writing. Because the logo, barcode or text is not merely ink printed onto the parts surface, it cannot be washed off and is not susceptible to abrasion. Instead it is permanently burned into the material itself making it very resistant to wear.

Lasers mark your designs with the highest precision onto the parts and can achieve an extremely high degree of detail. Moreover, since every design is saved as a file you can reproduce them at the same level of quality.

About laser marking by uv laser: https://www.rfhtech.com/s9-series-3w-5w-10w-uv-laser_p9.html

Laser Engraving

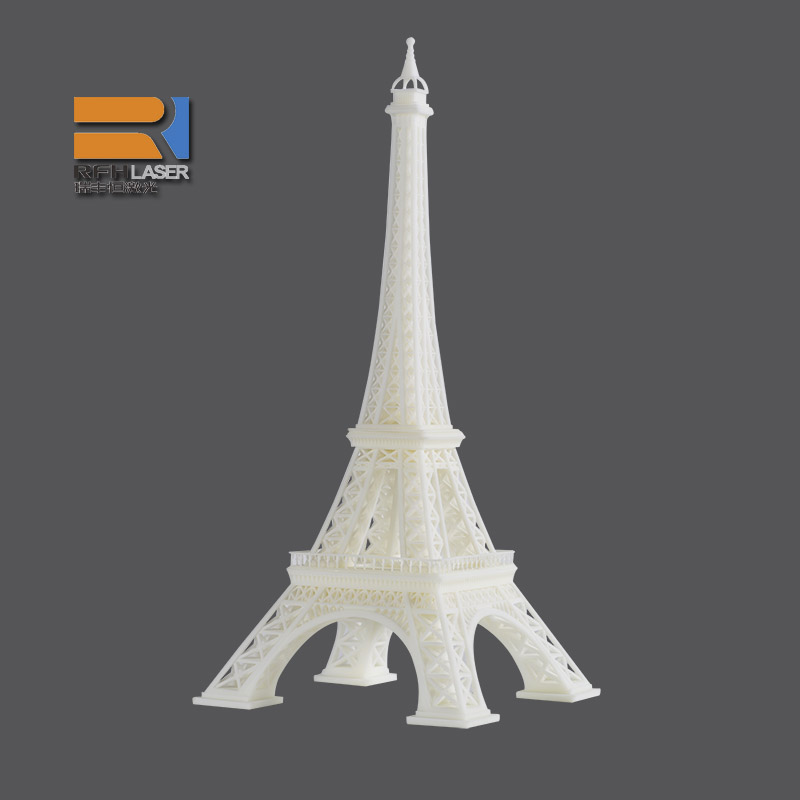

Image of Laser Marking , Laser Engraving & Laser Etching – The Differences: Laser Engraving

How does Laser Engraving work?

The high heat of the laser beam vaporizes the material thereby cutting into the part’s surface and physically removing material. This process leaves a cavity in the surfaces that is not only visible but also noticeable by touch. There are noteworthy differences in the depth of this cavity that varies between 0.02″ in metals to 0.125″ in harder materials.

What are the Differences to Laser Marking & Laser Etching?

Laser Engraving is the fastest of the technologies showcased here.?

Laser marking is not an abrasive process. Hence, it is the preferred method for applying bar codes, logos and the like on industrial parts.

Laser etching is also used to remove materials, but the depth of the cut is no more than 0.001″. Making this process ideal for objects made from precious metals.

Can I do Laser Engraving at home?

Yes, you can! Laser engraving is supported by most commercially available laser machines. The deciding factor that determines the operating mode is the intensity of the laser beam.

If you don’t want to spend money on a desktop laser marker, or just have one project to undertake, you can utilize an online laser processing service. There is a wide range of manufacturing services that offer laser marking, laser engraving, and laser etching. The most poular among these are probably Ponoko and Sculpteo.

What are typical applications of Laser Engraving?

This process has become very popular for customizing parts made off metal, plastics, wood, glass, and acrylic. In particular, it is a great tool to add numbers, logos, images and serial numbers to parts.

How does Laser Engraving compare to traditional techniques?

Laser engraving is a universal tool that can be applied to a wide range of materials. Meaning that you don’t need to buy dedicated tools for each of them. In short, one tool fits all.

When parts are engraved using mechanical tools it is necessary to fasten them with clamps. This adds to the work hours and may damage the parts. Since laser engraving is a contactless technology that does not require fastening parts, you save time and avoid the risk of damage the parts.

This also means that your tools like drills or cutters do not suffer from wear and need to be replaced saving you even more money.

Lasers engrave your designs with the highest precision onto the parts and can achieve an extremely high degree of detail. Moreover, since every design is saved as a file you can reproduce them at the same level of quality.

Traditional carpentry, wood-cutting and leather decorating are crafts that require long years of practical training to achieve mastery. Love it or hate it, but with laser engraving anyone can create items at a level of quality high enough to make a living! – Many people using laser engravings sell their goods on platforms like Etsy, Ponoko etc.

Laser Etching

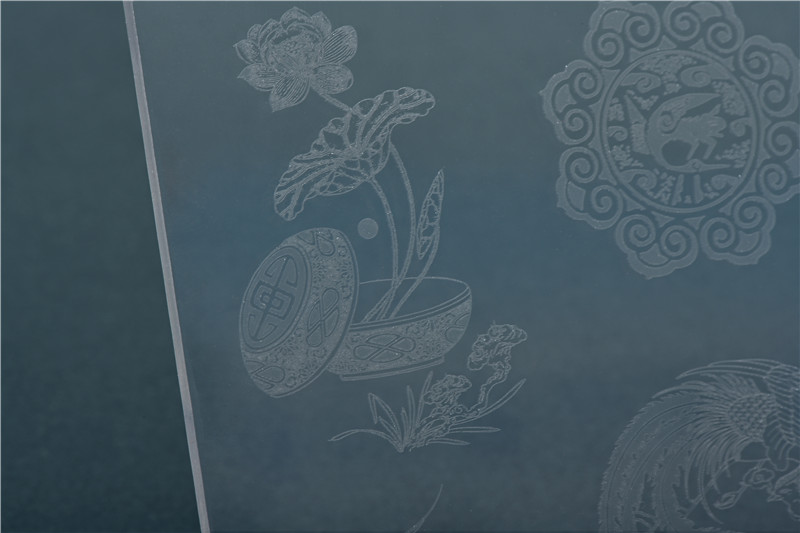

Image of Laser Marking , Laser Engraving & Laser Etching – The Differences: Laser Etching

How does Laser Etching work?

The laser beam heats up the material to the melting point. At this temperature, the material’s surface expands with a raised cavity. This process results in altered surface properties like reflectivity. In addition, it enhances the contrast of the work surface with the surrounding area.

What are the Differences to Laser Marking & Laser Engraving?

Laser etching is settled somewhere in between laser marking and laser engraving. Laser Engraving is the more radical process, as it can cut as deep as 0.125″, while laser marking only discolors the material’s surface leaving a high-contrast mark. Unlike the other two methods, laser etching leaves a raised outline on the surface.

Can I do Laser Etching at home?

Yes, you can! Laser etching is supported by most commercially available laser machines. The deciding factor that determines the operating mode is the intensity of the laser beam.

If you don’t want to spend money on a desktop laser marker, or just have one project to undertake, you can utilize an online laser processing service. There is a wide range of manufacturing services that offer laser marking, laser engraving, and laser etching. The most poular among these are probably Ponoko and Sculpteo.

What are typical applications of Laser Etching?

The depth of the laser etching cut is no more than 0.001″, making this process ideal for objects made from precious metals. Therefore, laser etching has become quite become for customizing jewelry.

How does Laser Etching compare to traditional techniques?

Laser etching is a universal tool that can be applied to a wide range of materials. Meaning that you don’t need to buy dedicated tools for each of them. In short, one tool fits all.

When parts are etched using mechanical tools it is necessary to fasten them with clamps. This adds to the work hours and may damage the parts. Since laser etching is a contactless technology that does not require fastening parts, you save time and avoid the risk of damage the parts.

This also means that your tools like drills or cutters do not suffer from wear and need to be replaced saving you even more money.

Lasers etch your designs with the highest precision onto the parts and can achieve an extremely high degree of detail. Moreover, since every design is saved as a file you can reproduce them at the same level of quality.

Traditional carpentry, wood-cutting and leather decorating are crafts that require long years of practical training to achieve mastery. Love it or hate it, but with laser etching anyone can create items at a level of quality high enough to make a living! – Many people using laser etching sell their goods on platforms like Etsy, Ponoko etc.

About laser etching by green laser: https://www.rfhtech.com/green-laser_c2