Laser has changed the era of crafts. Don't you know these laser engravings

Aug 10 , 2021Laser has changed the era of crafts. Don't you know these laser engravings?

In recent years, the increase of per capita income brought by the rapid economic development has greatly improved people's consumption level. In the field of industrial products consumption, people pursue exquisite and high-quality products, the social demand is gradually increasing, and the inner carving came into being.

In the traditional internal carving process, people often need to chisel the product, carve it inside, and finally use professional traceless glue for bonding. Despite the superb skills, it still caused damage to the handicrafts and seriously affected the beauty. In addition, the production efficiency was low, and the traditional inner carving gradually disappeared from people's vision

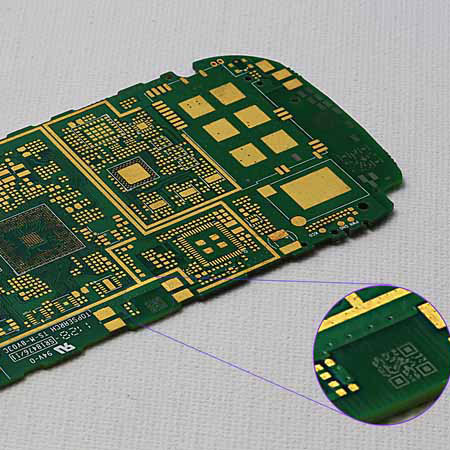

However, the laser inner carving has a pair of "perspective eyes", which can penetrate into the interior of the handicraft to find out. If you carefully observe the outside of the laser carved products, you will find that there is no trace of "carving knife" in and out.

In addition, traditional internal carving tests the skills of craftsmen, so it is easy to have different product quality. Furthermore, under the impetuous social atmosphere, it is difficult for the new generation of young people to calm down and learn a skill. The technical inheritance of traditional internal carving is facing difficulties, while the handicrafts produced by laser internal carving are easy to operate and consistent. Laser engraving: the crystallization of science and technology

In fact, it is also very simple. When the energy density of the laser is greater than a certain critical value (or threshold) to destroy the glass, the laser can penetrate the glass and enter the interior.

The energy density of a laser at a certain point is related to the size of its spot at that point. For the same laser, the smaller the spot, the greater the energy density. In this way, through proper focusing, the energy density of the laser can be lower than the damage threshold of the glass before entering the glass and reaching the processing area. The laser generates pulses in a very short time, and its energy can instantly heat and crack the crystal, so as to produce tiny white spots and carve a predetermined shape inside the glass, The rest of the glass or crystal remains intact.

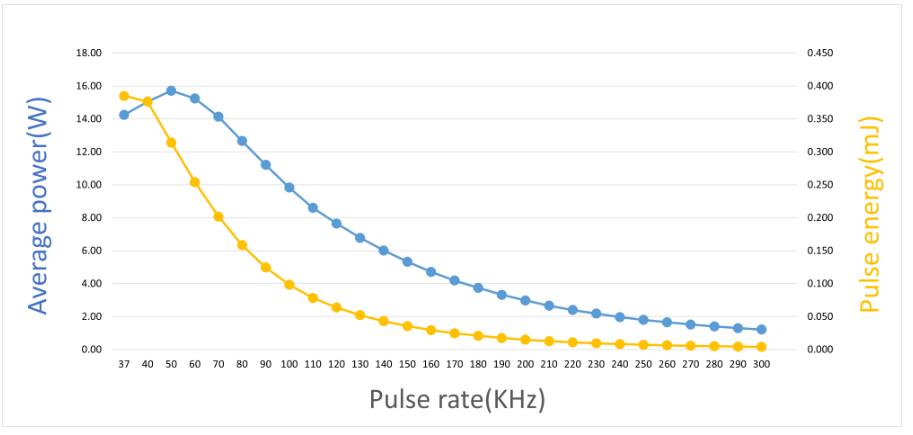

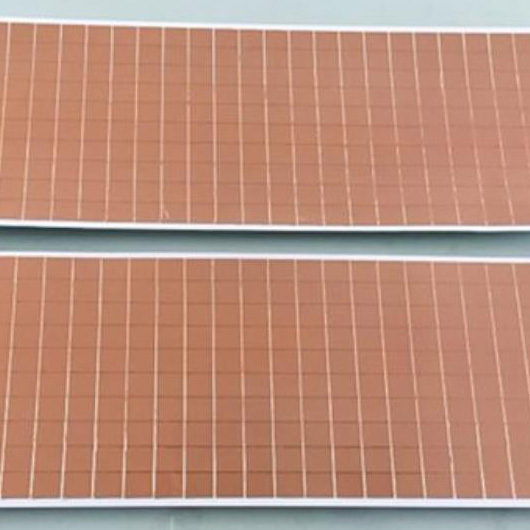

S9 UV laser This machine has a laser wavelength of 354.7nm and a wide coverage of repetition frequency (single pulse to 200kHz). When the laser beam is used for curve engraving in the product, it has no dust, volatile substances, emissions and consumables, does not pollute the external environment, and is easy to be absorbed, The characteristics of the short ultraviolet wavelength of this machine have advantages over the mechanical microprocessing of nonmetals and polymers. It can be focused on points of submicron order, so it can also be widely used in the processing of fine parts.

In addition, laser engraving is based on accurate numerical control technology. Even internal materials will melt and gasify instantly under the irradiation of laser, and carve exquisite three-dimensional or plane patterns customized by users. RFH S9 series UV solid-state lasers can also control the quality of each product through preset in advance, so you can give full play to it, Create your own graphic