RFH 3W10W UV laser engraves transparent plastic inside to solve the problem of surface explosion

Website: http://www.rfhtech.com

Whatsapp(Wechat): 18928466502

Email: export06@rfhlasertech.com

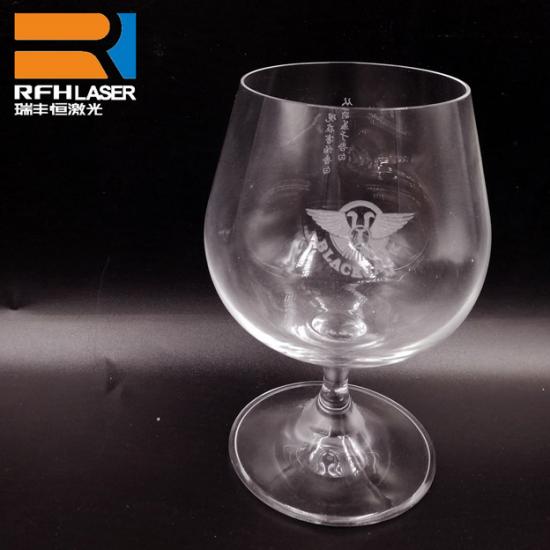

When it comes to internal carving, many people will definitely think of materials like glass and crystal. It must be admitted that the most common in-carving craftsmanship in real life is made of materials such as glass or crystal, and most of them are made into beautiful crafts.

However, internal carving is not exclusive to glass.

The RFH solid-state UV laser conquered the problem of plastic inner carving explosion points with its superb technology

In many industrial products, internal engraving technology is needed, and one of the more difficult to solve is the plastic material. Both glass and crystal are very stable. RFH laser has already broken through the crystal engraving process, but the plastic is different.

Plastic is unstable, and the power requirements of the laser are extremely high. If there is a slight difference, the problem of surface explosion will occur. Now, the RFH laser has broken through the internal engraving of plastic and solved all the problems.

RFH Douyin-Plastic Inner Carving Demonstration

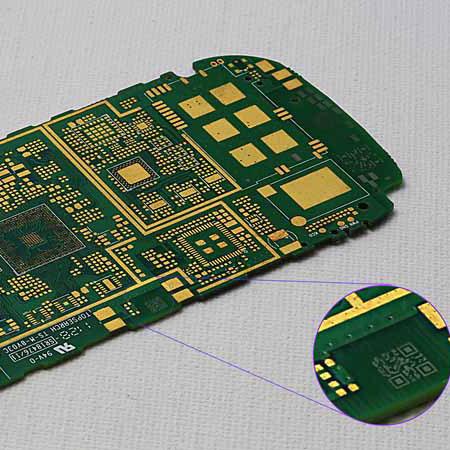

In industrial products, many plastic parts need to use the in-carving process. According to the previous process, plastic parts will definitely have a parting line. This not only affects the beauty of the parts, but also affects the quality in more serious cases. The introduction of laser technology can solve this problem.

If you want to achieve sharp characters and clear images, a single RFH S9 ultraviolet laser can solve the problem.

RFH S9 UV laser

The introduction of the RFH S9 series of ultraviolet lasers has solved the three major difficulties of plastic internal engraving:

01

Power Control:

To achieve perfect plastic inner engraving, laser power control is the most important thing. In addition to accuracy, precise control is also required. The RFH S9 series of ultraviolet lasers use numerical control technology, all of which are adjusted by precise numbers, which can more accurately control the laser power and various parameters.

In the face of unstable materials such as plastics, the laser internal engraving process can be very smooth through the unified control of the computer.

02

Laser quality:

Engraving facing the plastic material requires very high beam quality of the laser. The RFH S9 series ultraviolet laser has a laser wavelength of 354.7nm, a wide range of repetition frequency (single pulse to 200khz), and the processing precision is concentrated to the micron level, which can accurately control the accuracy.

With such a high laser quality, even processing some precision plastic parts is no problem.

03

Processing cost:

No matter how fine the processing is, it is difficult to put it into mass production if the cost is too high.

The RFH S9 series has a very small volume, a very high degree of integration of the fuselage, no need to make a large optical path, a small footprint, and a lower cost. And RFH has a very good technical team to support, quality is also guaranteed, especially for power control related technologies, RFH leads the industry.

Power supply stability is the basis of laser stability. RFH S9 series UV lasers have excellent power supply design, stable operation and longer life.

Breakthrough time after time, RFH only presents you with higher quality UV lasers

Breakthroughs, attempts, and again, the RFH laser has conquered the plastic inner engraving process. The inner engraved characters and patterns are clear and sharp, making the industrial products show the most perfect performance. At the same time of good quality, it can achieve extremely strong scalability and lower use cost. This is the confidence guarantee that RFH gives users.

uv laser | green laser | Ultraviolet lasers | uv dpss laser | nanosecond laser | UV laser source | Solid State Lasers