S9 UV laser marks crystal complex patterns and characters, with smooth edges and no burrs

Website: http://www.rfhtech.com

Whatsapp(Wechat): 18928466502

Email: export06@rfhlasertech.com

Everyone likes crystals that are crystal clear, and there are many objects in life that need to use crystal material, but the hardness of the crystal is 7 and it is relatively brittle. If you don't pay attention to it, you may damage the entire material when carving.

Although crystal processing is very difficult, the "crystal color filling" process is also indispensable. In the past, a very strong process was required to complete the exquisite color filling process.

The traditional crystal coloring process is definitely a kung fu job

The traditional crystal coloring process is definitely a work, and it is difficult to keep the color depth consistent without a few years of training. In traditional processing, the processing master polishes a certain depth by hand. The crystal products processed in this way are very exquisite, but the processing is also very difficult.

In view of the high hardness of the crystal, it is very important to master the strength when processing crystal products, otherwise the depth of the coloring will be destroyed, and the finished product will be presented in different depths. Moreover, a little carelessness with high crystal brittleness will destroy the entire material, which will eventually lead to a decline in the yield rate.

What are the advantages of traditional processing methods?

"

The biggest advantage of the traditional crystal coloring process is personalization.

What to engrave on the crystal material, how to choose the font, all can be customized, which is a gap with pure crafts using molds. Life does need a lot of unique information to be presented. At this time, personalization is particularly important.

What are the disadvantages of traditional processing methods?

"

The biggest disadvantage of using manual crystal coloring is undoubtedly low efficiency and low processing accuracy.

In the processing of many products, the traditional handicraft color filling obviously can not keep up with the demand, and the yield rate is not high, the processing accuracy is very low, and it is a bit weak in the face of precision processing.

How to engrave patterns in the beloved glass crystal, see RFH ultraviolet laser

When the crystal coloring process takes into account individuality, efficiency and precision, the laser can take the crystal coloring process to a higher level, which is a non-contact processing method.

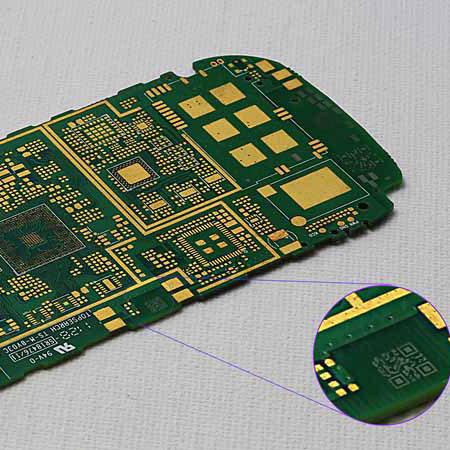

The picture below is the effect of RFH laser using crystal color filling process. Precise control can make the color filling process very precise.

Using laser coloring, the color depth can be easily kept consistent, and the desired pattern can be personalized according to the needs, and the accuracy is very high. (The Rolex LOGO in the picture below is only 0.8mm in size)

How does RFH achieve such a sophisticated coloring process?

In the face of industrialization today, RFH takes advantage of the high single-pulse energy characteristics of UV lasers to instantly form explosive points (vaporization) in the glass performance. Through precise power control, the depth of filling is kept highly consistent, and the final product is exquisite.

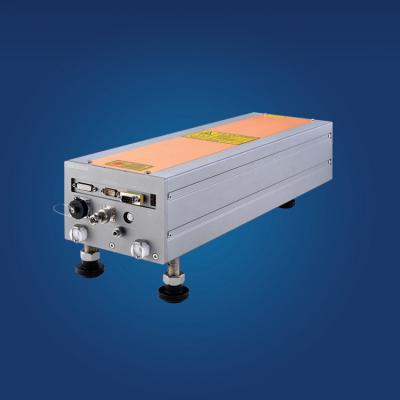

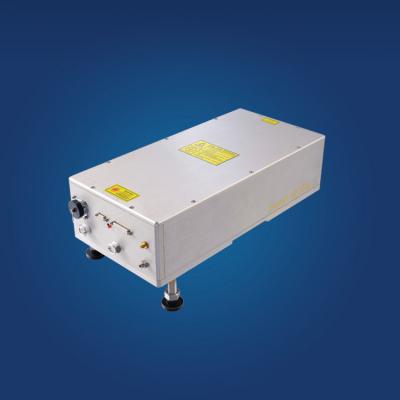

RFH uses the latest S9 series of ultraviolet lasers to deal with complex patterns and texts, with sharp edges without burrs and consistent depth.

The RFH S9 series of UV lasers are very compact, saving space, avoiding large optical paths, reducing costs, and ensuring good product rates.

Of course, to ensure the yield rate, an excellent technical team is indispensable. RFH uses industry-leading power supply design to ensure the stable power and quality of the laser, and strives to build the S9 series of ultraviolet lasers.

RFH UV laser has accumulated a very good reputation in the glass marking industry

With the efforts of the RFH technical team, the RFH S9 series of UV lasers can achieve full digital control. Each parameter can be adjusted through a computer, which is not only intuitive, but also can be customized to meet the needs of crystal coloring to meet the needs of different scenarios.

RFH has accumulated a very good reputation in the industry through 15 years of R&D and technology accumulation, and has continuously overcome the difficulties of traditional industries through new laser technology, reducing costs while improving yield and product technology. All the difficulties of traditional craftsmanship are avoided, and it has never been easier to fill crystals. RFH laser solves it in one step.

uv laser | green laser | Ultraviolet lasers | uv dpss laser | nanosecond laser | UV laser source | Solid State Lasers