Exquisite ceramic engraving and drilling can not be separated from UV laser

Website: http://www.rfhtech.com

Whatsapp(Wechat): 18928466502

Email: export06@rfhlasertech.com

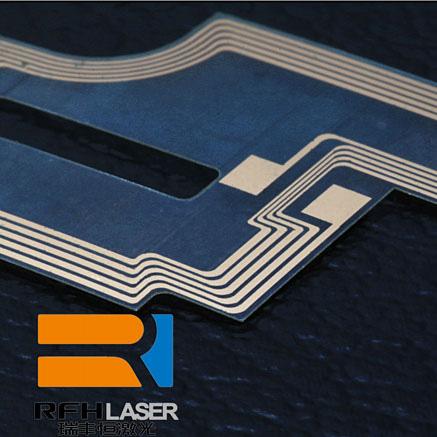

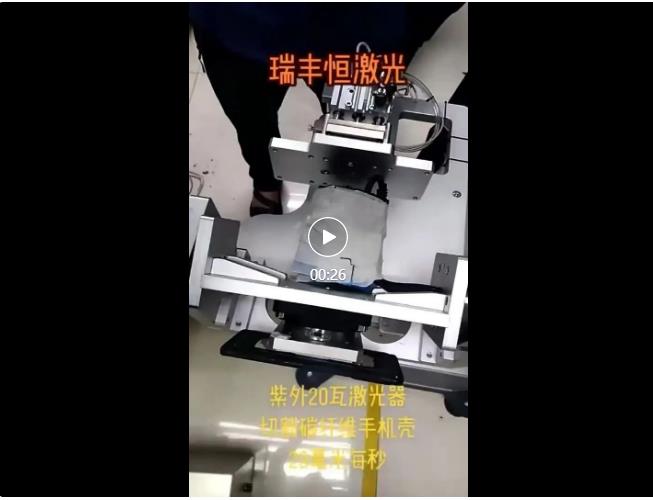

20w high power UV laser cutting carbon fiber without carbonization

When it comes to carbon fiber, I believe many friends are very familiar with it. Although it is not a new material, in many fields such as medical, aerospace, automobile, and military, the excellent performance of carbon fiber is still irreplaceable. Special existence.

The main reasons why carbon fiber has been called the "king of materials" for a long time are:

High strength and light weight

The biggest advantage of carbon fiber is that its strength is higher than that of steel, but its weight is only 1/5 of the latter. Because of this, carbon fiber materials are widely used in automotive, aerospace, military and other fields, and cannot be replaced temporarily.

Strong toughness

Compared with steel, carbon fiber is extremely tough and can be easily crimped, which is a particularly great advantage for basic materials, providing convenience in terms of transportation or processing.

good stability

After using carbon fiber to assemble the finished product, it is not as easy to be corroded by acid and alkali as common metal materials.

Excellent shock resistance

The last huge advantage is the seismic performance. The parts processed by carbon fiber have excellent elastic modulus, whether it is creep resistance, tensile resistance or shock resistance, the performance is much higher than that of steel.

It is precisely because carbon fiber has such high performance advantages that with the development of science and technology, this material has also been devolved from high-end fields such as military industry to the civilian level.

As long as you make good use of the characteristics of light weight, high strength and excellent shock resistance, there are many mobile phone cases made of carbon fiber materials on the market.

However, the processing of such consumer-grade electronic accessories requires very high precision. Although carbon fiber has the above advantages, in the field of processing, the brittleness of carbon fiber is infinitely magnified.

Especially when precise cutting is performed at the end of processing, traditional tools obviously cannot meet the requirements of precise cutting. At this time, it is necessary to use a "contactless processing" method such as laser.

Through the 20W high-power ultraviolet laser, Ruifengheng can not only cut accurately, but also have a processing speed of 20mm/s, quickly and efficiently complete the processing of consumer-grade electronic parts, minimize the cost of carbon fiber processing, reduce man-hours for processing enterprises, and improve efficiency.

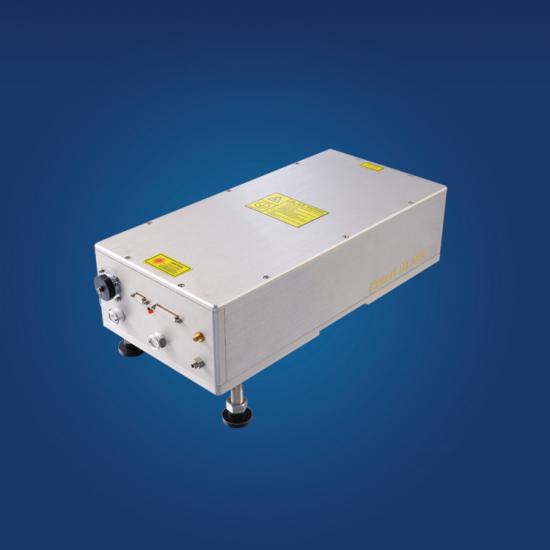

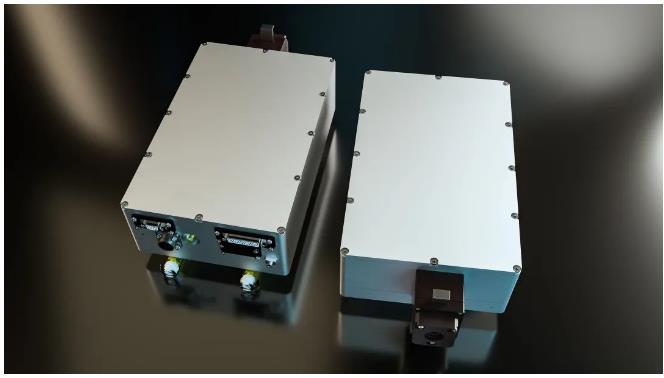

Ruifengheng Expert III 355 High Power Ultraviolet Pulsed Solid State Laser

As Ruifengheng's latest high-power UV laser, Expert III 355 has superior beam quality (M2<1.2), strictly guaranteed in all frequency ranges, and pulse width <25ns@100k, with very small heat-affected area during processing .

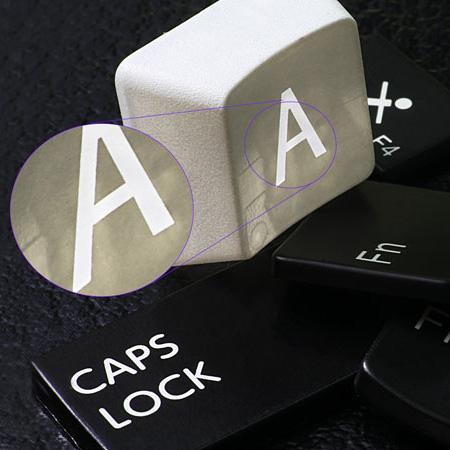

For the processing of carbon fiber, the heat-affected area is small, and the high precision of ±0.02mm means that the cutting edge is smooth without burrs, deformation and other problems, and it is easy to achieve high yield.

In addition, Ruifengheng Expert III 355 adopts unique Q-switching control technology, which is suitable for various laser application control requirements. The compact size can be integrated with various equipment, and at the same time, there is no need to enlarge the optical path, which reduces the processing threshold and cost.

Ruifengheng has strong technical strength in power supply. Through self-developed power supply technology and internal cavity self-purification system, the laser has a long life and stable operation.

In terms of control and maintenance, Ruifengheng Expert III 355 adopts all-digital intelligent power control technology, which is easy to operate, easy to monitor, and supports communication with a computer. The laser can be controlled externally through RS232.

In the era of digital processing, using Ruifengheng laser products, you can enjoy the latest technological dividends, easily handle new material processing, save worry and money for manufacturers, benefit the majority of users, and set an industry model.