Website: http://www.rfhtech.com

Whatsapp(Wechat): 18928466502

Email: export06@rfhlasertech.com

355nm short wavelength high-power UV pulsed solid-state laser engraving acrylic crystal lamp

Everyone should be familiar with laser engraving. In modern industrial products, laser engraving can be seen everywhere. Permanent marks are marked on the surface of items through laser beams. Whether it is for personalization or other needs, laser engraving is the most convenient one. Processing methods.

Since the vast majority of laser engravings are "thermal processing", a beam with extremely high energy density is required to irradiate the object to be processed, resulting in melting, ablation or evaporation. In thermal processing, CO2 lasers are the most common type, leaving traces on the surface of objects with a laser wavelength of 10.64um.

However, as a gas laser, CO2 laser is mainly used on non-metallic materials, and because of its low price, it has a high penetration rate, but the disadvantage of low precision is also an unavoidable problem.

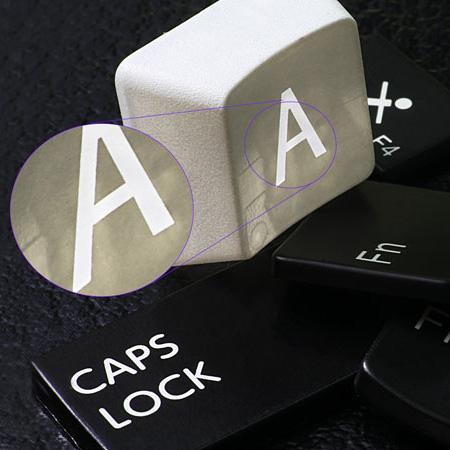

Different from the more destructive method of "thermal processing", "cold processing" can be achieved by using a high-energy UV laser, which has less thermal impact and can achieve more accurate laser engraving processing.

The principle of ultraviolet laser is different from the former. It breaks the chemical bonds in the material (especially organic materials) or the surrounding medium through ultraviolet light molecules, so that the material is destroyed by a non-thermal process, which belongs to the cold peeling of chemical bonds. The layer and surrounding areas do not experience heating or thermal deformation.

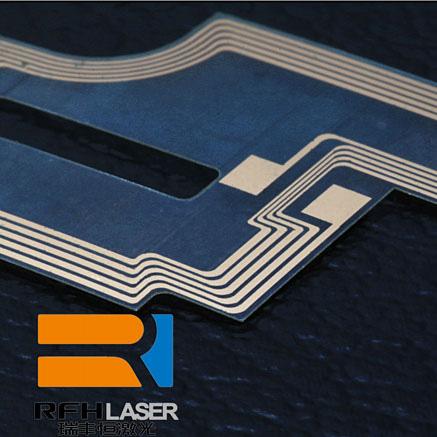

RFH realizes the precision processing of acrylic lamp post art laser engraving through 15W ultraviolet laser, the processing spot is extremely small, so the heat affected area can be almost ignored. When processed by high-power ultraviolet laser, not only ultra-fine marking can be achieved, but also special materials can be marked, which is also the preferred benchmark for high-demand processing.

There are generally two wavelengths of UV solid-state lasers: 355 nm and 266 nm. The RFH Expert III 355 high-power UV pulsed solid-state laser is a high-power UV laser with a wavelength of 355 nm.

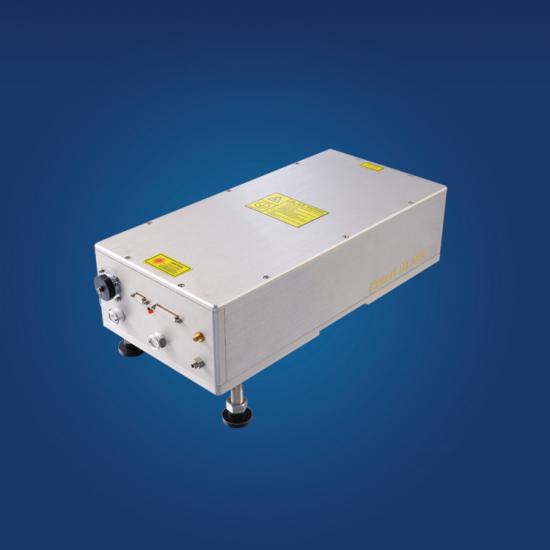

RFH Expert III 355 High Power UV Pulsed Solid State Laser:

The laser wavelength of RFH Expert III 355 is 354.7nm, wide repetition rate coverage (single pulse to 200kHz), excellent beam quality (M2<1.2), strictly guaranteed in all frequency ranges; pulse width <25ns@50k, The heat-affected area is very small during processing, and it has a high precision of ±0.02mm, which is the first choice for precision machining.

In terms of power supply technology, RFH Expert III 355 uses a unique Q-switching control technology, which is suitable for various laser application control needs, and adds an internal cavity self-purification system to make the laser long life and stable operation.

In addition, the all-digital intelligent power control technology is easy to operate, easy to monitor, and easier to use in the face of precision machining

With such powerful performance, the RFH Expert III 355 has an unparalleled compact size. Thanks to the integrated design, it is easy to integrate with other equipment, and it does not need to enlarge the optical path, reducing costs for enterprises and improving the degree of freedom of use.

In the era of digital processing, RFH Expert III 355 not only supports full digital power control, but also supports communication with a computer. It can externally control the laser through RS232 to accurately complete various command requirements.

Under the general trend of Industry 4.0, intelligent processing and digital processing are basic requirements. With the advancement of the torrent of the times, RFH laser has continuously improved its technology, released the pace of innovation, and solved various problems of laser processing to obtain the best user experience. High-power ultraviolet lasers are widely popularized, and new product iterations provide users with the best choice to help the transformation of Industry 4.0.