355nm UV laser for IC chip cleaning

Unlocking the Power of 355nm UV Laser: Revolutionizing IC Chip Cleaning for Enhanced Performance

Integrated circuit (IC) chips, the heart and soul of modern electronics, have become increasingly complex and powerful over the years. As these chips continue to shrink in size and pack more functionality, the need for precision cleaning becomes paramount. Enter the 355nm ultraviolet (UV) laser, a groundbreaking technology that is transforming the way IC chips are cleaned, ensuring optimal performance, and prolonging their lifespan.

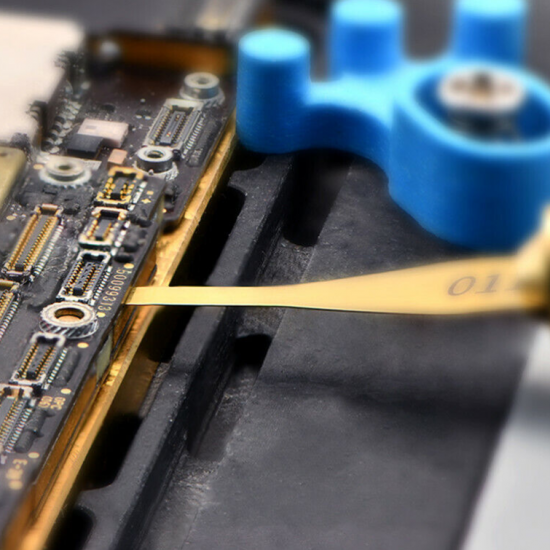

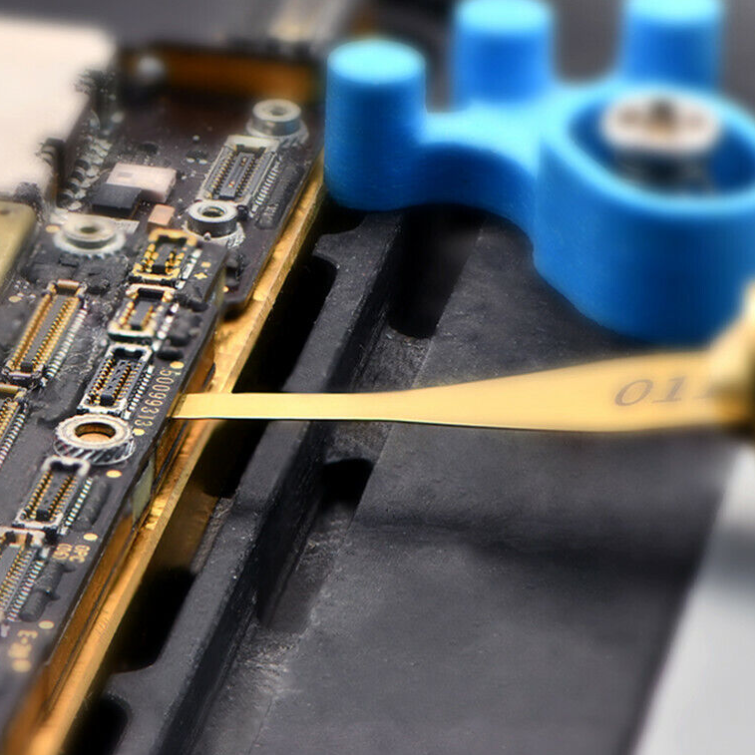

The 355nm UV laser is a game-changer in IC chip cleaning, offering a level of precision and efficiency that traditional methods simply cannot match. With its ultra-short pulse duration and pinpoint accuracy, this laser has the ability to remove microscopic contaminants, residues, and even oxides from delicate IC chip surfaces without causing damage or compromising the integrity of the chip itself.

One of the key advantages of the 355nm UV laser lies in its ability to selectively target and remove specific contaminants. Whether it's organic residues, metal impurities, or oxides, the laser's ultraviolet wavelength enables it to interact with these substances, breaking their molecular bonds and effectively vaporizing them. This targeted approach ensures thorough cleaning without affecting the surrounding chip components, avoiding potential damage or degradation.

Moreover, the 355nm UV laser operates at a wavelength that is highly absorbed by many common contaminants found on IC chips. This characteristic allows for efficient and effective cleaning, as the laser energy is efficiently converted into thermal energy upon absorption, resulting in the rapid removal of contaminants. This not only saves time but also enhances the overall cleaning quality, leaving behind pristine chip surfaces ready for further processing.

In addition to its exceptional cleaning capabilities, the 355nm UV laser offers unparalleled precision. The laser beam can be selectively focused on specific areas, enabling technicians to clean even the tiniest features and intricate parts of the IC chip. Whether it's removing residues from narrow channels, cleaning in-between closely spaced circuitry, or clearing debris from microstructures, the laser's high-resolution cleaning ensures the chip's functionality remains unaffected while reducing the risk of shorts or malfunctions.

Furthermore, the 355nm UV laser ensures minimal thermal impact during the cleaning process. While traditional cleaning methods such as chemical solutions or abrasive techniques can generate heat, potentially leading to thermal stress and degradation of the chip, the laser's non-contact nature prevents any heat transfer to the chip surface. This non-thermal cleaning approach minimizes the risk of thermal damage and contributes to the overall longevity of the IC chip.

The benefits of the 355nm UV laser extend beyond cleaning efficiency and precision. This technology also offers environmental advantages, as it eliminates the need for chemical solvents or harsh cleaning agents that can be harmful to both human health and the environment. By utilizing the power of ultraviolet light, the laser provides a safe and eco-friendly cleaning solution, reducing waste generation and promoting sustainable practices within the electronics industry.

As the demand for smaller, faster, and more reliable electronic devices continues to grow, the importance of IC chip cleanliness cannot be overstated. Even the tiniest particle or trace of contaminants can hinder performance, affect signal integrity, and compromise the overall functionality of the chip. The 355nm UV laser emerges as the ideal solution, effectively addressing the challenges associated with maintaining clean IC chip surfaces.

In summary, the 355nm UV laser is revolutionizing IC chip cleaning, offering unparalleled precision, efficiency, and environmental sustainability. Its ability to selectively target contaminants, high-resolution cleaning, minimal thermal impact, and eco-friendly approach make it an indispensable tool for electronics manufacturers, semiconductor companies, and research laboratories.

As technology advances and IC chips become even more intricate, the power of the 355nm UV laser will continue to play a significant role in ensuring optimal chip performance and reliability. By embracing this cutting-edge technology, the electronics industry can unlock the full potential of IC chips, ultimately driving innovation, powering the connected world, and transforming the way we live, work, and communicate.