355nm UV laser is continuously praised by customers for laser paint stripping

Keyboard marking processing, using 355nm ultraviolet laser to become the mainstream

Ultraviolet laser used for peeling paint on keyboard keys

With advanced technology and excellent product quality, RFH UV laser has an increasing market share of laser peeling paint

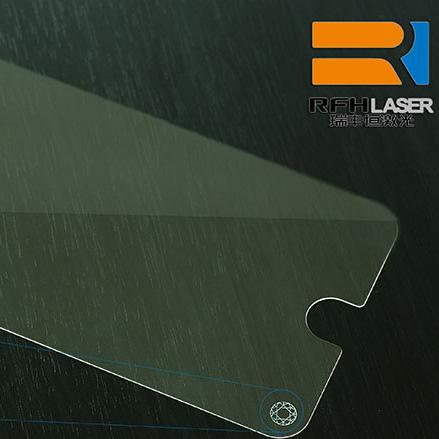

The plastic products we use in our daily work, such as computers, mobile phones, electrical appliances, packaging boxes and other plastic items have text or patterns on them. If you want to print the text patterns on these plastic items coated with paint, you must use them Laser peeling paint process.

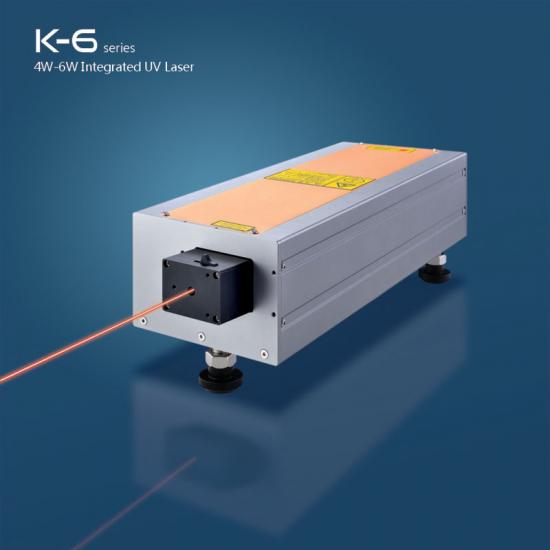

The main equipment in the laser peeling process equipment is the laser, and the stability of the laser determines the peeling effect. Since the RFH 355nm UV laser was put into the market, it has been continuously receiving praise from customers, especially in the laser paint stripping industry. With advanced technology and excellent product quality, the market share is getting higher and higher.

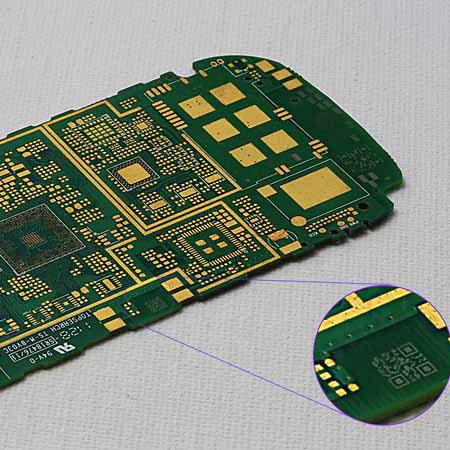

Recently, a keyboard key marking machine manufacturer purchased an RFH 355nm ultraviolet laser for keyboard marking processing. The mark marked with UV laser will not fade and fall off easily, and can be maintained for a long time. Ultraviolet laser replaces the traditional manual printing, voltage, pressure dye printing and inkjet water printing, computer engraving, corrosion (etching) and other processes in the past; the craftsmanship is excellent, the marking is clear and eye-catching, the wear resistance is strong, and the logo is retained, so the ultraviolet laser The keyboard logo has become the mainstream.

For keyboard marking processing, RFH recommends that you choose to use RFH high-quality ultraviolet laser-355nm ultraviolet laser. The help it brings to manufacturers is multi-layered.

The marking effect is more refined

The RFH 355nm ultraviolet laser has a short pulse width (<20ns@30k), a small heat-affected area during processing, and superior beam quality (M2<1.2). It is strictly guaranteed in all frequency ranges and has perfect spot characteristics (spot ellipticity>90 %), therefore, it is so simple to complete high-precision marking tasks.

Marking is faster and more efficient

In just 1 second, the RFH laser can process and mark several production dates and production batch numbers, with fast speed and high stability, and the assembly line can achieve high-speed and efficient processing and production.

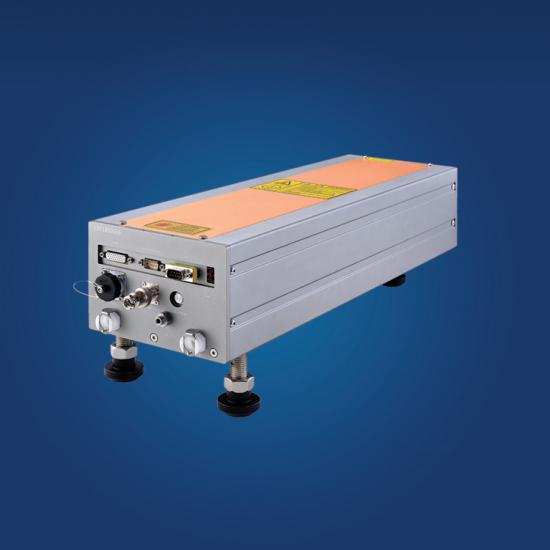

reduce manufacturing cost

The RFH laser contains an internal cavity self-purification system, so the laser has a long life and durability. In addition, it also has unique Q-switching control technology, which can be suitable for various laser application control needs. One machine is multi-purpose and simple to operate. It can meet the manufacturers' multiple production application needs. In the long run, it can reduce the construction cost of a large number of new production lines for manufacturers. Really save worry and effort.

RFH has been based in the nanosecond laser industry for 13 years. In the 13 years of hard work, it has accumulated strong technical strength, enabling laser products to maintain consistent stable quality, constant beam quality and under extreme industrial and scientific research conditions. The characteristics of high efficiency and durability have won the high recognition and good reputation of domestic and foreign industry users.