SLA light-curing 3D printer manufacturer buys RFH 355 ultraviolet laser

Diode pumped solid-state laser, wavelength 355nm, used for 3D SLA light curing

355nm UV laser used in SLA 3D printer

Today, we received an inquiries from SLA light-curing industrial-grade 3D printer manufacturers. Laser type requirements: diode-pumped solid-state laser, wavelength 355nm.

We recommend the RFH Expert Ⅱ 355nm UV laser to our customers. This model has excellent spot quality M²<1.2; export spot ellipticity>95%; fast cutting and marking speed; high precision, high power stability; internal cavity The self-purification system, the laser is long-lived and durable; the unique Q-switching control technology is suitable for various laser application control needs, and it also supports communication with the computer, which can maintain consistent and stable quality under extreme industrial and scientific research conditions.

The superior quality of this UV laser is due to RFH Laser’s R&D technology and rigorous production management system:

With a doctoral-level R&D team as a solid technical backing, with self-developed all-digital intelligent power control technology, it can update the power control system functional modules in time, and improve the functional modules according to laser requirements to ensure stable performance; unique Q-adjustment control The technology makes it suitable for various laser application control needs, and the internal cavity self-purification system makes it long and durable.

In production, every detail is strictly controlled. From purchasing, pre-production quality inspection, to assembly process, finished product testing, to warehouse quality inspection and pre-delivery inspection, each level is checked to ensure stable quality and consistency of equipment parameters with actual operating parameters. This is one of the reasons why the service life of RFH brand lasers is better than that of peers.

SLA light-curing industrial-grade 3D printer manufacturers placed an order to buy the RFH 355 ultraviolet laser without saying a word.

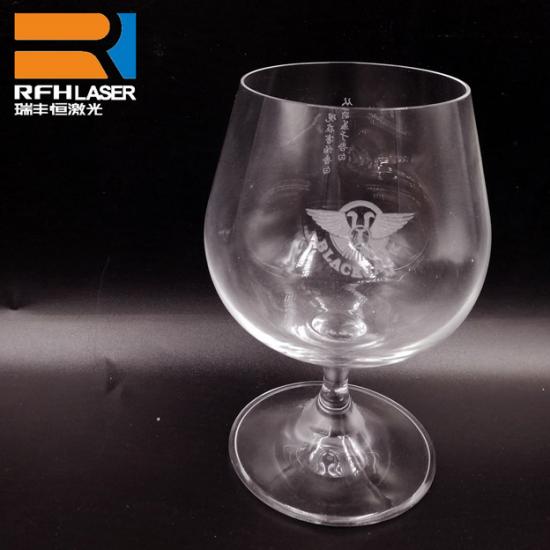

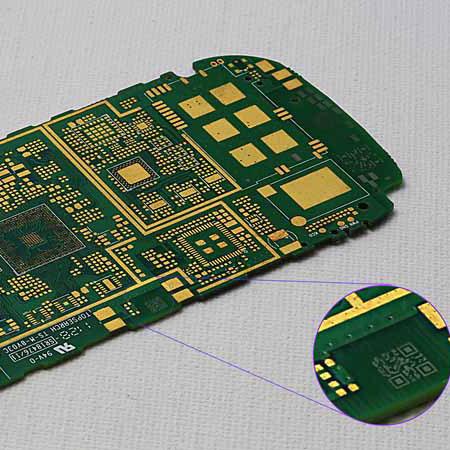

RFH products are geared towards laser end users and system integrators, covering a range of lasers ranging from green to deep ultraviolet. The range of laser pulse energy, average power and repetition frequency can be applied to diversified laser fields, such as consumer electronics, electronic circuits, and packaging. Printing, solar energy, lithium batteries, semiconductor microelectronics, panel displays, jewelry, biomedicine, automotive industry, aerospace and other industries. Lasers are widely used in 3D printing rapid prototyping, precision marking, precision drilling, precision cutting, laser welding, plastic laser welding, metal laser welding, laser medical treatment, surface removal, wire stripping, internal carving and other laser applications.

The RFH laser product line is complete, with a rigorous quality management system, and the whole process of production in a dust-free workshop. The quality control department strictly controls the incoming materials, production, machine acceptance, and shipment links to ensure product performance and quality.

Rigorous quality management system process:

a. Procurement

Cooperate with domestic and foreign first-line brand suppliers to ensure the stable quality of each component

b. Quality control before production

Test each part to ensure that the parts are 100% qualified before entering the production material reserve

c. Production in the whole dust-free workshop

d. Rigorous assembly process

Early-stage wiring-testing and sealing-debugging, layer by layer check, quality assurance

e. Finished product testing

All products have passed strict aging tests, and product parameters such as power, beam quality, spot ellipticity, and beam pointing stability must be 100% up to standard

f. Inbound quality inspection

Strictly follow the "Product Storage Inspection Standards", and the machine parameters and accessories conform to 100% before the storage is allowed

g. Shipment

Before delivery, turn on the equipment again to check the power, spot ellipticity, beam direction, and other parameters, and the accuracy rate reaches 100% before delivery is allowed to ensure the consistency of equipment operation under different environments.

h. After-sales

18-month warranty period, 24 hours a day after-sales response service, Wuhan, Suzhou set up offices;