355nm UV nanosecond laser's cold marking technology attracts attention

Aug 03 , 2022355nm UV nanosecond laser's cold marking technology attracts attention

Laser processing technology has achieved rapid development in recent years, and its application fields cover automobile manufacturing, aerospace, integrated circuits, consumer electronics, display panels, medical and health care, power energy, and other emerging industries. With high processing efficiency, low energy consumption and high flexibility, laser processing is gradually replacing traditional processing techniques, whether it is macro processing or more subtle micro-processing fields.

In the field of laser fine micromachining, the 355nm ultraviolet nanosecond laser has the advantages of short wavelength, short pulse, high beam quality, small size, high efficiency, "cold" processing, etc. It is an ideal and reliable light source for laser processing such as drilling, cutting, and scribing, and in order to meet the increasingly stringent precision requirements of micro-processing, especially in the context of the critical period of transformation and upgrading of my country's manufacturing industry, 355nm ultraviolet nanosecond solid-state lasers have become attractive. One of the eye-catching lasers.

The "coldness" of 355nm UV nanosecond lasers

In material processing, visible and infrared lasers are mainly focused on the focus for localized heating, so that the material is melted or gasified for processing. This is a heat treatment process, and a wide heat-affected zone can easily affect the quality of laser processing, such as Melt, carbonization and other phenomena occur at the edge of cutting or drilling, so the overall accuracy is not high, the edge is not neat, and even requires secondary processing.

The single-photon energy of 355nm ultraviolet light is high, about 3.5eV, and the chemical bond energy of C-C bond and C-N bond is about 3.4eV and 3.17eV, respectively, so it may be directly interrupted on materials containing C-C bonds and C-N bonds. Molecular bonds are separated from the surface of the material. This way of working will not generate high heat, the degree of thermal influence is very low, the mechanical deformation of the material is greatly reduced, and the thermal influence of processing is small, avoiding the long-wavelength laser processing. Thermal defects and deficiencies, coupled with the generally high absorption rate of most materials to 355nm ultraviolet light, so the use of 355nm ultraviolet laser processing can also be called "cold processing", which is very sensitive to thermal effects, such as carbon polymer, ITO film , glass, sapphire, silicon wafer and other materials are of great significance for fine micro-processing.

The "hot" of 355nm UV nanosecond lasers

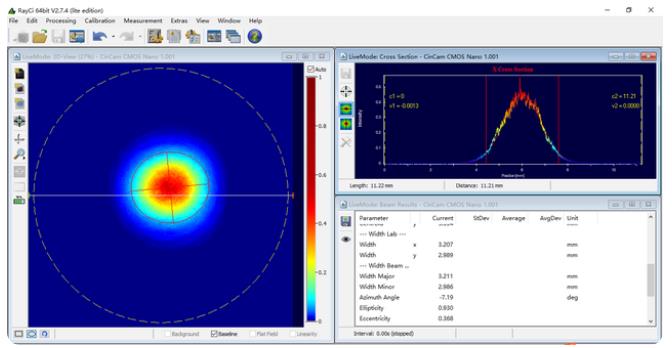

The characteristics of "cold" processing make 355nm UV nanosecond lasers very useful in the field of micromachining. In the application of laser marking, the beam quality of 355nm ultraviolet light is good, the focusing spot is extremely small, up to 10-20um, which can realize ultra-fine marking, clear and firm, better than ordinary ink coding and pollution-free, and can maintain excellent quality positioning accuracy. The marked graphic information has higher contrast, higher resolution and smoother edges.

With the continuous breakthrough of laser technology and the continuous improvement of laser processing efficiency and requirements for industrial applications on the market, the power of 355nm ultraviolet nanosecond lasers has been continuously increased, from 3W, 5W, to 10W, 15W, and then to 20W , 30 W continues to extend, higher power means higher processing efficiency, the use of 355nm ultraviolet nanosecond laser for high-precision cutting, drilling, etching applications is more and more widely, such as FPC flexible circuit board cutting, silicon wafer Chip micro-hole, blind hole processing, LCD liquid crystal glass cutting, glassware surface drilling, and solar panel etching, etc., is a veritable all-rounder. With the development of emerging industries such as 5G industry, solar cells, lithium batteries, and panel displays, the market demand for 355nm ultraviolet nanosecond lasers with higher power and higher repetition frequency will grow rapidly.

The positive market feedback continues, and the shipments of 355nm UV nanosecond lasers are outstanding. A research report shows that in 2019, the shipments of UV lasers in my country were 19,000 units, of which 17,465 units of nanosecond UV lasers were shipped, accounting for 92% of the total. %.

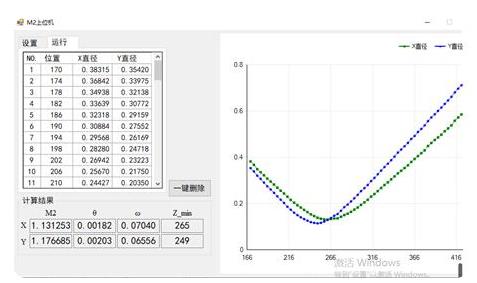

In order to adapt to the improvement of industrial processing precision requirements, the 355nm UV nanosecond laser has high stability, compact structure, high beam quality (M2<1.2), and has a variety of power options, which can meet most industrial precision processing requirements.