3w5w UV laser engraving QR code inside plastic bottle cap

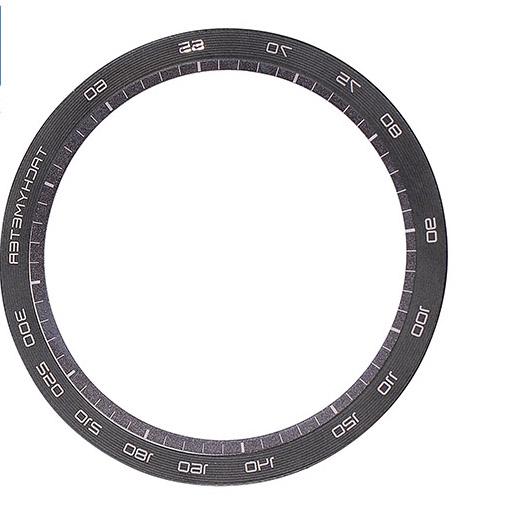

355nm UV laser marking QR code inside beverage plastic bottle cap

355nm UV laser has a short pulse width

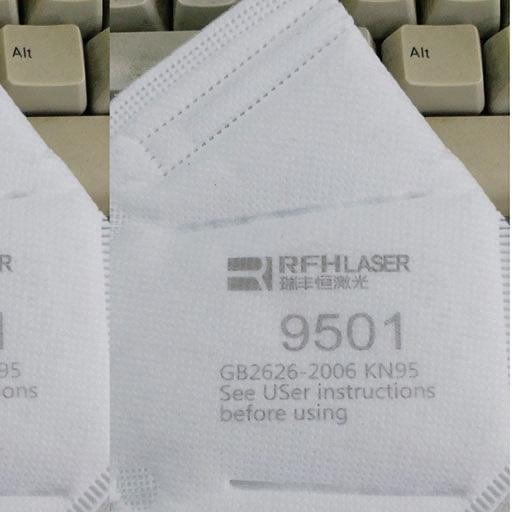

For the marking of the date and date of the beverage bottle and cap, the RFH 355nm ultraviolet laser is used, which reflects the flying water marking.

Mobile payment applications are becoming more and more widespread, and scanning codes has become a very common thing. You may have to scan the QR code with your mobile phone many times a day when you are in a car, shopping, or eating. The QR code is a bit "sad", and the winning QR code is very happy. Every time the RFH laser editor scans out the words "One more bottle", I feel that the sweetness doubles and the happiness doubles!

"One more bottle" is a little surprise hidden in the QR code of the beverage bottle cap. Do you all know? This surprise was carved out by laser irradiation.

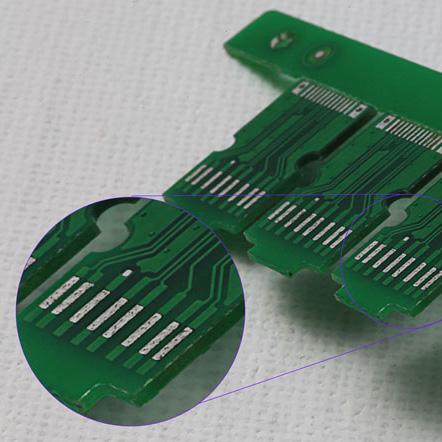

First, draw a two-dimensional code plan in the laser marking software, then set the laser output power, marking speed and other parameters, and then turn on the equipment for automatic processing, and it's done.

This process may seem simple, but it is not. It seems simple because the laser equipment is used for automatic processing, but it is not because the laser processing system is not simple. Because the beverage bottle cap is made of plastic material, the quality of the laser beam is very high, and a slight deviation will produce a batch of products (assembly line operation).

This requirement, for the RFH high-quality UV laser with 12 years of technology, is of course easy to meet.

RFH 355nm UV laser has a short pulse width (<14ns@30K), superior beam quality (M2<1.2) and perfect spot characteristics (spot ellipticity>90%) (3W-5W Expert Ⅱ 355nm series), It can maintain consistent and stable quality under extreme conditions of industry and scientific research. Therefore, marking plastic bottle caps is fast and good, and the marked two-dimensional code is clear and beautiful, which greatly improves the yield rate of assembly line production.

Of course, it can do more. It has a unique Q-switching control technology, which is suitable for various laser application control needs. In addition to marking the production date of plastic bottle caps, it can also be competent for other purposes. One machine has multiple functions. At the same time, it also contains an internal cavity self-purification system, which makes the laser long life and cost-effective. It is a high-efficiency production assistant for laser marking manufacturers.

Each laser product developed and produced by RFH can maintain consistent and stable quality, constant beam quality, and high-efficiency power consumption under extreme industrial and scientific research conditions. With its high cost performance and high reliability, it has won all walks of life at home and abroad. Highly recognized by users and a good monument. After 12 years of hard work, we have established an excellent brand image in the nanosecond laser industry.