5 watt ultraviolet laser for Glass Laser Micro Drilling

The Marvel of Glass Laser Micro Drilling Unveiled by the 5 Watt Ultraviolet Laser

When it comes to precision drilling in the world of glass, traditional methods often fall short in achieving impeccable accuracy and finesse. However, a revolutionary technology has emerged that is transforming the landscape of glass micro drilling - the 5 watt ultraviolet laser. With its unparalleled power and precision, this advanced laser solution has opened up a realm of possibilities for industries that require intricate and flawless micro drilling on glass surfaces.

The 5 watt ultraviolet laser stands as a testament to the extraordinary capabilities of modern laser technology. By harnessing the power of ultraviolet light at an impressive wattage, this laser system can perform micro drilling with utmost precision and efficiency on glass, even at the smallest scales. This game-changing technology has overcome the limitations of traditional drilling methods, such as mechanical stress, thermal damage, and restricted hole size, taking glass micro drilling to an entirely new level.

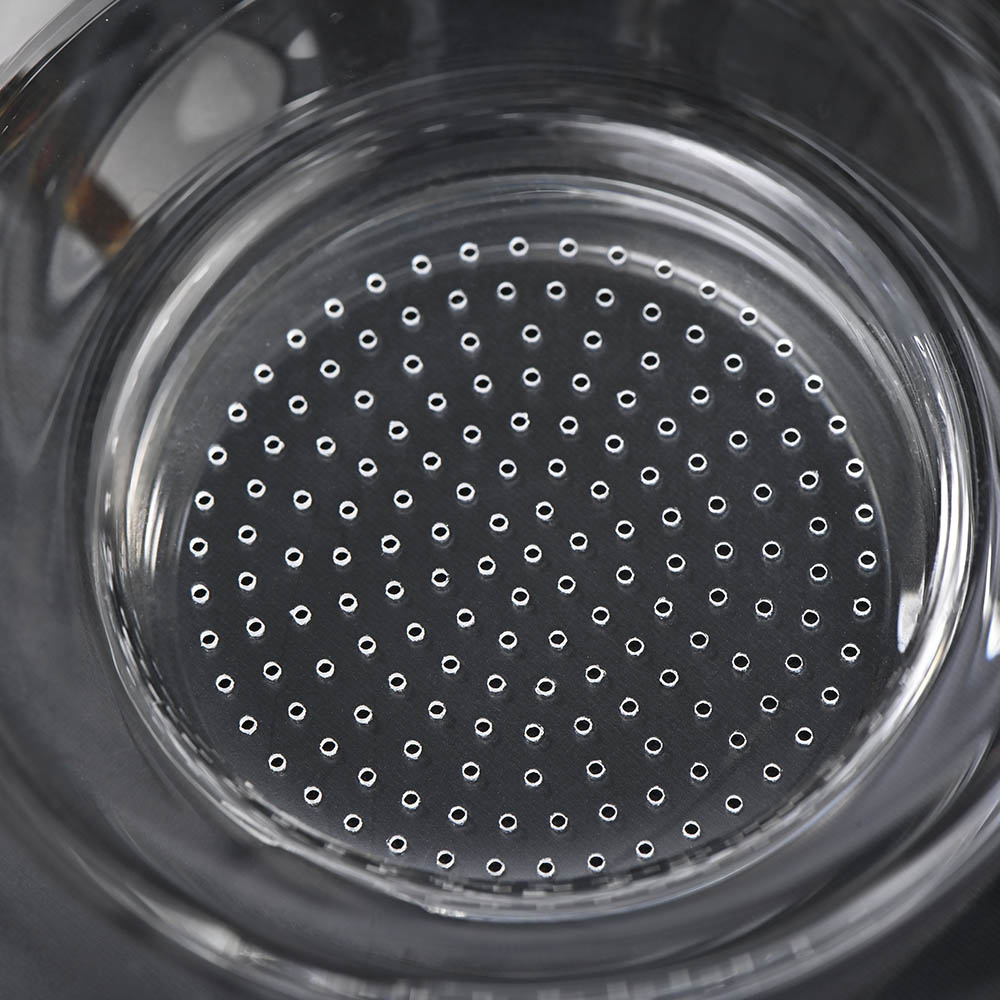

One of the key advantages of the 5 watt ultraviolet laser in glass micro drilling is its ability to generate extremely fine and accurate holes. With its focused beam size and high energy density, this laser can create holes in the glass that are of superior quality, enabling industries to achieve their desired results while maintaining the structural integrity of the material. Whether it's for medical devices, electronics, or even artistic glasswork, the precision offered by the 5 watt ultraviolet laser ensures flawless micro drilling that meets the highest standards of craftsmanship.

Speed is another remarkable aspect of the 5 watt ultraviolet laser. With its powerful beam and efficient energy transfer, this laser system can complete the drilling process in a fraction of the time compared to conventional methods. This not only increases productivity and throughput but also reduces production costs, making it an ideal choice for industries that require high-volume or time-sensitive glass micro drilling applications.

Moreover, the 5 watt ultraviolet laser offers exceptional versatility in terms of the glass materials it can handle. Whether it's soda-lime glass, borosilicate glass, or even specialty glasses, such as sapphire or quartz, this laser system can deliver consistent and precise micro drilling across a wide range of glass substrates. This adaptability enables industries to explore new possibilities in design and engineering, pushing the boundaries of what is achievable in glass micro drilling applications.

Durability is another standout feature of the 5 watt ultraviolet laser. The holes created by this laser system exhibit remarkable resistance to cracking, chipping, or other forms of damage, ensuring the longevity and reliability of the drilled glass components. This is particularly crucial in industries such as optics or telecommunications, where the stability and performance of the drilled glass parts are of utmost importance.

Furthermore, the 5 watt ultraviolet laser offers a safer and cleaner alternative to conventional drilling methods. With its non-contact nature and precise control, this laser system eliminates the need for mechanical force or chemical drilling solutions, reducing the risk of contamination or operator exposure to hazardous substances. In addition, the focused beam enables minimal collateral damage to the surrounding glass surface, resulting in cleaner and more aesthetically pleasing micro-drilled holes.

In conclusion, the 5 watt ultraviolet laser has revolutionized the realm of glass micro drilling, setting new standards of precision, speed, versatility, and durability. Its unrivaled power and efficiency in creating flawless holes make it an indispensable tool across a wide range of industries, from electronics and medical devices to architecture and creative glasswork. As industries continue to push the boundaries of design and engineering, the 5 watt ultraviolet laser stands as a shining beacon of innovation, unlocking the limitless potential of glass micro drilling.