Cutting Flexible PCB with RFH 15W and 20W UV Laser Source

Flexible printed circuit boards (PCBs) have become increasingly popular in various electronic devices due to their bendable and lightweight properties. To ensure precise and efficient cutting of flexible PCBs, RFH 15W and 20W UV laser sources have emerged as the ideal choice. In this article, we will delve into the benefits and advancements of RFH UV laser technology for cutting flexible PCBs.

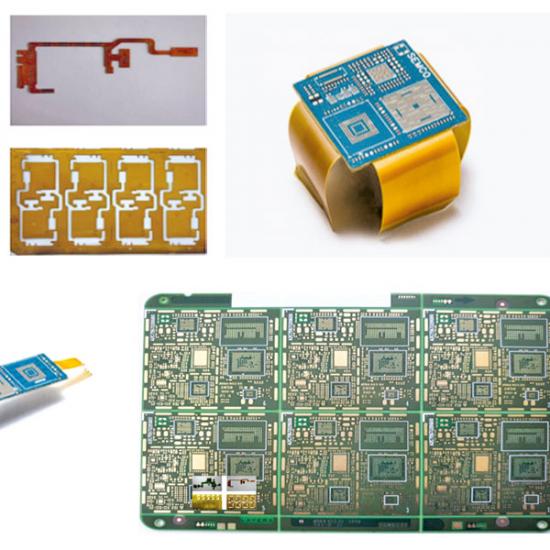

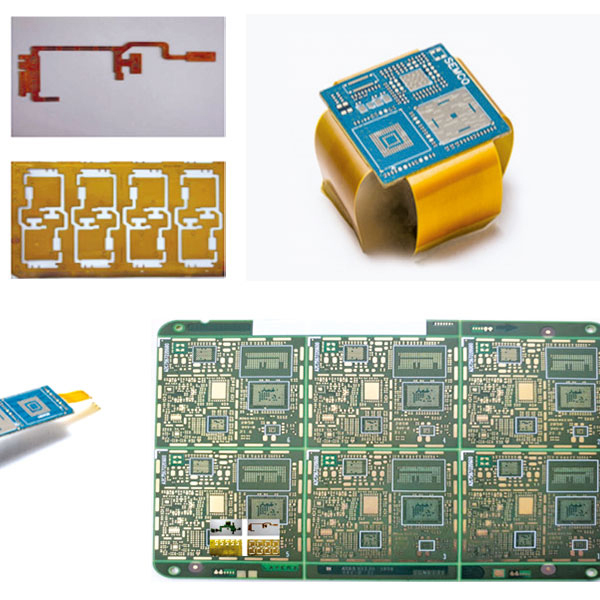

The demand for flexible PCBs has grown rapidly with the advancement of wearable technology, foldable displays, and flexible electronics. These circuit boards, made from polyimide or polyester film, offer unmatched flexibility, reliability, and miniaturization capabilities. However, the traditional method of mechanical cutting poses challenges such as limited precision, slow production speed, and potential damage to delicate components. This is where the RFH 15W and 20W UV laser sources come into play, revolutionizing the cutting process.

RFH, a renowned provider of laser solutions, has introduced their cutting-edge 15W and 20W UV laser sources specifically designed for flexible PCB cutting. These lasers emit high-intensity ultraviolet light, which is absorbed by the material and instantly vaporizes it, resulting in precise and clean cuts. Additionally, RFH lasers offer excellent beam quality, ensuring minimal heat-affected zones and negligible charring, thus preserving the integrity of the PCB.

One of the key advantages of using RFH UV laser sources for flexible PCB cutting is their exceptional precision. The focused laser beam can easily be adjusted and controlled to achieve intricate patterns and complex designs with micron-level accuracy. This level of precision reduces the margin of error and enhances the overall functionality and reliability of the PCBs. Moreover, RFH lasers can handle high-speed cutting, significantly improving production efficiency.

The RFH 15W and 20W UV laser sources also exhibit remarkable stability and longevity. These lasers boast a long service life, ensuring consistent performance and reduced maintenance requirements. The stability of the laser beam enables continuous cutting without interruptions or quality degradation, resulting in higher productivity and cost-effectiveness for manufacturers.

As the demand for flexible PCBs continues to rise, RFH 15W and 20W UV laser sources prove to be indispensable tools for efficient and precise cutting. With their superior precision, stability, and longevity, RFH lasers enable manufacturers to optimize production processes and deliver high-quality flexible PCBs for various industries. Embracing RFH UV laser technology is a transformative step towards revolutionizing the manufacturing landscape and meeting the ever-evolving needs of the electronics industry.ry.