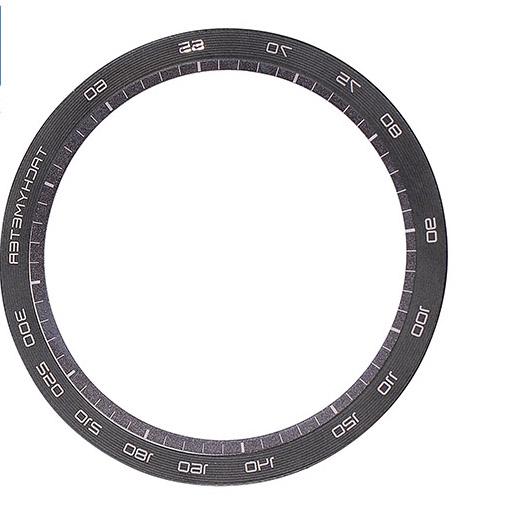

High-speed engraving of text and LOGO on switch panel by UV laser

Engraving text on the plastic switch, use a 3W ultraviolet laser

What laser light source is good for switch engraving logo

Title 2: Engraving text or LOGO on plastic switch panel, RFH ultraviolet laser: fast speed, high precision, high stability

Laser marking can use three kinds of light sources, such as fiber laser, CO2 laser, and ultraviolet laser.

Fiber laser, usually used for marking and engraving on the surface of metal objects;

CO2 laser, usually used for fabric, acrylic engraving and cutting;

The ultraviolet laser is used in the plastic marking industry in a dominant position, and neither optical fiber nor CO2 can shake its position.

Therefore, the engraving on the switch panel, the engraving of text on the plastic switch, and the engraving of the logo on the switch are non-UV laser sources.

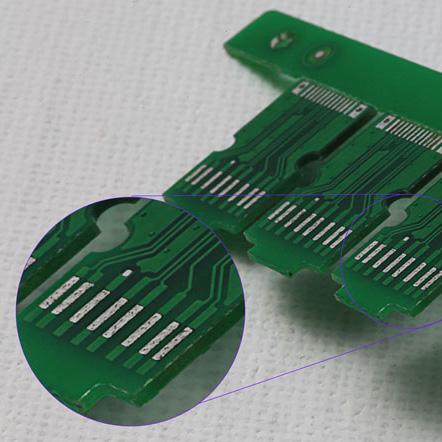

The 355nm ultraviolet laser has a very small focus spot and a small processing heat-affected zone, so there is almost no damage caused by heat, so it is called a cold light source. Because of the extremely small heat-affected area of the UV laser, there is no thermal effect, and the deformation or scorching of the processed material is avoided.

Ultraviolet laser marking is to use the laser thermal effect to ablate the surface material of the object, thereby leaving a permanent mark. It has the advantages of non-contact marking, low cost, no consumables, good permanence, no deformation, no pollution, high speed, high stability, and high precision engraving.

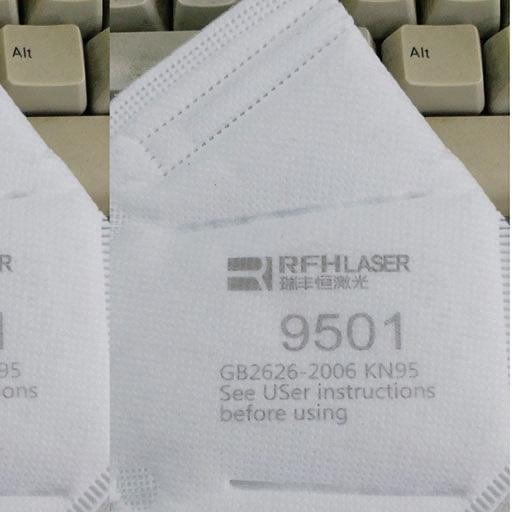

For engraving text or LOGO on the plastic switch panel, it is recommended to use the RFH Expert Ⅱ 355nm ultraviolet laser. This model has three distinctive features: high speed, high precision and high stability, and is suitable for high-speed assembly line marking.

The laser developed by RFH also has a fully digital intelligent power control technology independently developed by the RFH doctoral level R&D team, which can update the power control system function modules in time, and improve the function modules according to laser requirements; it has an internal cavity self-purification system to ensure the life of the laser Long, stable operation; integrated design, convenient equipment integration; with unique Q-switching control technology, suitable for various laser application control needs, with it, it is so simple to expand the laser marking business.

RFH's 12 years of hard work has not only been satisfied with manufacturing high-quality lasers, we have also launched a complete system sales plan for power supply + laser + cooling system from the perspective of users to ensure the stability of the entire laser system and its best performance. Because of this, we have won high recognition and good reputation from users in all walks of life at home and abroad, and established an excellent brand image in the nanosecond laser industry.