Korean Customers Embrace 5W UV Laser for Bar Code and QR Code Engraving on White ID Wristbands

In the bustling streets of Korea, a trend has emerged, pushing the boundaries of wristband customization to new heights. As technology continues its relentless advance, the Korean customer seeks nothing less than excellence when it comes to personalization. Enter the 5W UV laser, a groundbreaking tool that has captured the imagination of Korean wristband enthusiasts, as they delve into the realm of bar code and QR code engraving on pristine white ID wristbands made of luxurious silicone.

The allure of these seemingly innocuous wristbands lies not only in their functional purpose but also in their ability to make a bold and artistic statement. Korea, a hub of innovation and creativity, embraces the fusion of technology and fashion, elevating wristbands to a realm of artistic mastery. By utilizing the 5W UV laser, enthusiasts can now engrave intricate bar codes and captivating QR codes on the elegant canvas of white ID wristbands, transforming them into miniature works of art.

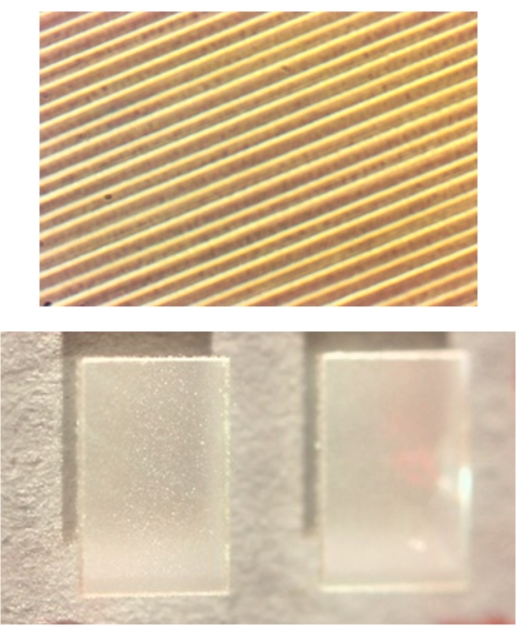

What makes the 5W UV laser so remarkable? Its precision and power are unrivaled, allowing for the creation of stunningly detailed engravings. Against the pristine white backdrop, the contrasting black engravings create a visual masterpiece, capturing attention and igniting the curiosity of onlookers. The intricate patterns of bar codes and QR codes breathe new life into the wristbands, transcending their mere utilitarian purpose.

The impact of these engraved wristbands reaches far beyond their aesthetic appeal. Bar codes have long served as efficient tools for encoding data and providing seamless identification. By incorporating bar codes into the realm of wristbands, Korean customers have unlocked a realm of endless possibilities. These wristbands not only showcase personal style but also facilitate effortless access to important data or information with a simple scan.

QR codes, on the other hand, take this connectivity to the next level. More complex and visually captivating, QR codes weave a mesmerizing tapestry of black and white squares, each holding a treasure trove of information. With a swift scan, these enigmatic codes unlock online connections, contact details, or event information, effortlessly enhancing the wearer's digital experience.

In the hands of Korean customers, the art of engraving bar codes and QR codes onto white ID wristbands becomes a form of self-expression. Each intricately engraved design reflects the individual's personality, capturing their unique story in a subtle yet visually striking manner. These wristbands become wearable art, encapsulating the essence of personal identity and serving as a testament to the harmonious fusion of technology, creativity, and fashion.

As Korean customers continue to embrace the 5W UV laser and its transformative capabilities, the world of personalized wristbands expands. No longer simple accessories, these wristbands elevate to a new level of sophistication and glamour. Bar code and QR code engraving on white ID wristbands showcases the brilliance of Korean ingenuity and the limitless possibilities that lie at the intersection of technology and aesthetics.

In the vibrant tapestry of Korean culture, wristbands engraved with bar codes and QR codes represent the synergy of tradition and innovation. These stunning wristbands pay homage to the legacy of craftsmanship while boldly embracing the modern era. As technology continues to evolve, Korean customers remain at the forefront, driving the evolution of wristband personalization, forever pushing the boundaries of what is possible.