Laser carving wood, ultraviolet laser technology is much better than CO2 laser marking

RFH UV laser is currently a very popular wood marking processing technology on the market. It can allow wood crafts to achieve the required effect and benefit more manufacturers from it.

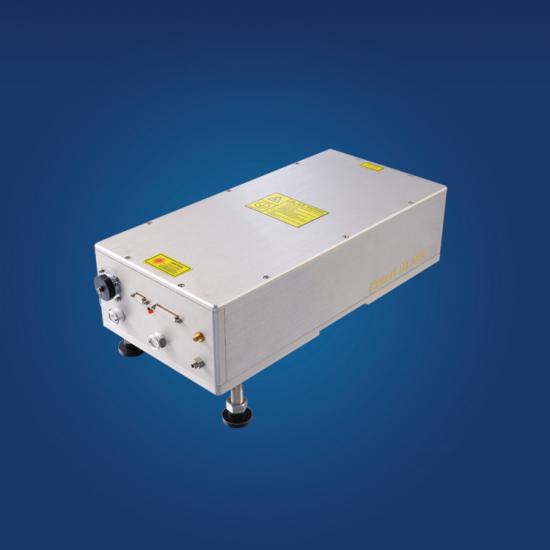

RFH 10W UV laser is a new technology for labeling of wood crafts. It is also the technology of the forefront, practical, and very suitable for small and medium -sized enterprises to master the production of production.

The RFH UV laser needs to be reached by the production method that needs to be reached through the consumables. Instead, the laser is marked through different frequencies. The launch of the laser is high and the thermal effect is small. The accuracy of the processing is about 0.02mm, which meets the current market requirements.

In addition, the RFH UV laser is equipped with parts of first -line brands at home and abroad, and all have passed strict quality inspections to largely ensure the coordination and use of parts. The degree of departure program setting, the degree of marking under control, has also been better guaranteed in terms of operation safety.

The current technology and R & D UV lasers are in line with the needs of the market, and it can allow small and medium -sized enterprises to have more space for personalized research and development while completing the order. It fully meets the requirements of current small and medium -sized enterprises. Said.