Which brand of UV laser is more stable

What is the difference between an air-cooled UV laser and a water-cooled UV laser

Longer life, characteristic of RFH UV laser

Since last week, many laser processing plants have resumed work and production, and industry development has gradually returned to the right track. RFH Laser has learned from some manufacturers that the turnover will decline to a certain extent in the near future, but it will continue to rise in the future.

On the other hand, the new bosses are also confident about this. No, several bosses consulted us last week, asking which one is the stable UV laser? Regarding this question, everyone will have a good idea after reading this analysis article by RFH.

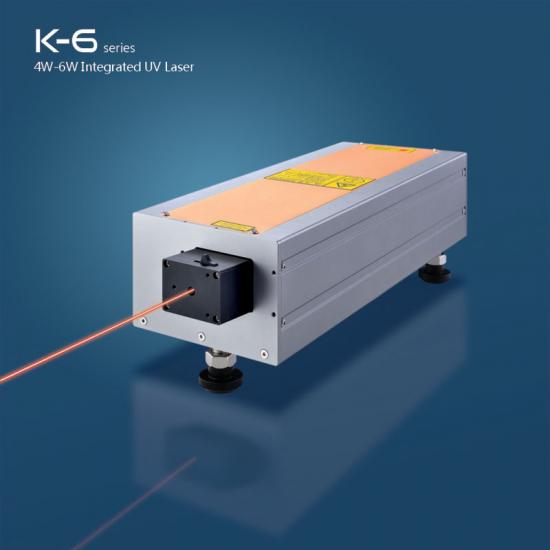

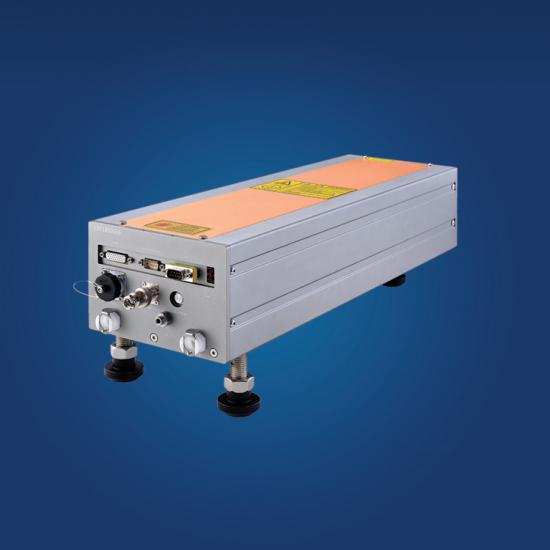

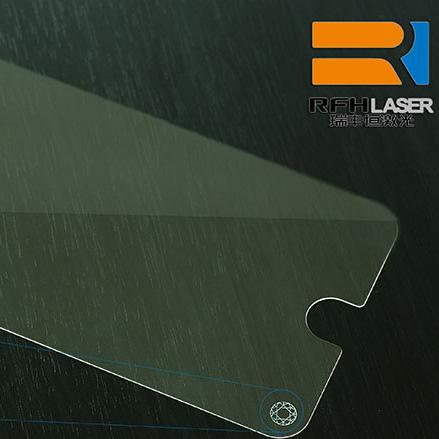

First, let's understand what types of UV lasers are available. Currently, there are two types of UV lasers: air-cooled and water-cooled. As the name suggests, it is air cooling and water cooling. Generally, high-power ultraviolet lasers generate more heat when they work, so they are cooled by water, otherwise they are cooled by air. Relatively speaking, the water-cooled type is more powerful, but the volume is larger and the power consumption is higher. Therefore, you can choose the UV laser equipment with the appropriate power according to the actual production needs, and comprehensively consider the power consumption cost.

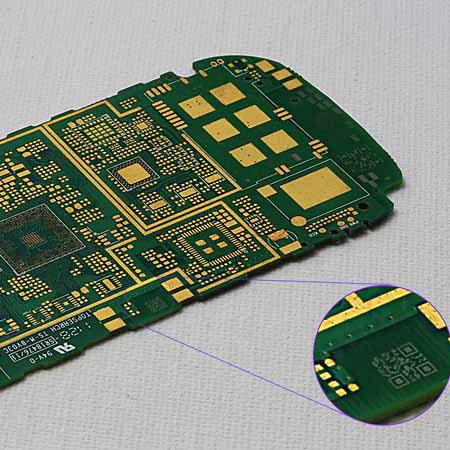

At present, there are not many domestic UV laser manufacturers, and the strongest is Shenzhen RFH Laser Company. RFH UV laser is currently at the first-class level in the industry. It not only has superior performance, stable processing effect, fast processing speed, and high cost performance.

But I want to say that choosing a company depends on its after-sales service quality in addition to product quality.

The warranty period of RFH laser products is 18 months, which is 6 months longer than most companies. This is not only our confidence in product quality, but also our confidence in our complete management system:

The pump and Q-switch core components of RFH UV lasers are all imported brands, and the components are in cooperation with domestic first-line brand suppliers. From the source of the material procurement ecological chain, to ensure the quality of each part is a guarantee for users to use RFH brand lasers with confidence. Then go to production, testing, warehousing, and delivery, to ensure stable quality and consistency of equipment parameters with actual operating parameters. This is the reason for the long service life of RFH lasers. An old customer once praised this feature like this: the years are passing, and the stable performance of RFH's UV laser continues.

After many years of use, any equipment will have problems such as aging and malfunctions. At this time, after-sales service is required. RFH Laser 24/7 after-sales service responds quickly, and multiple offices across the country provide you with convenient technical support.

Now, do you know how to choose a UV laser?