Which light source is good for ceramic marking machine?

RFH UV laser light source is more suitable for ceramic marking

Marking ceramic materials, choose UV laser

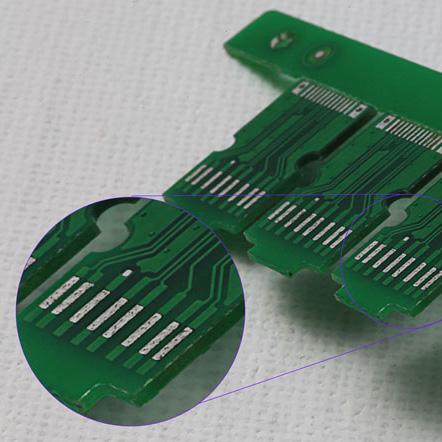

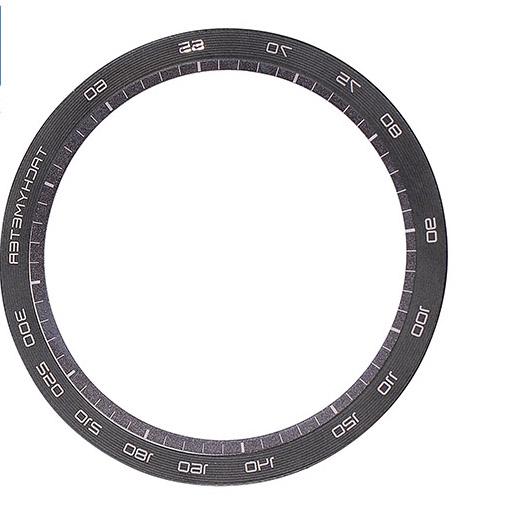

Laser marking is clear, durable, and beautiful. The engraved objects have fine patterns and can be marked in batches, which greatly saves costs for enterprises. There are many types of laser marking light sources, such as fiber lasers, CO2 lasers, and ultraviolet lasers, but ultraviolet lasers are cold light sources, which have little effect on marking heat, and solve the problems of thermal deformation and scorching of processed materials, and the beam quality is high, and the focused spot Small, can achieve ultra-fine marking, high speed, wide application range, low energy consumption, environmental protection, no consumables, it is the best choice for ceramic marking.

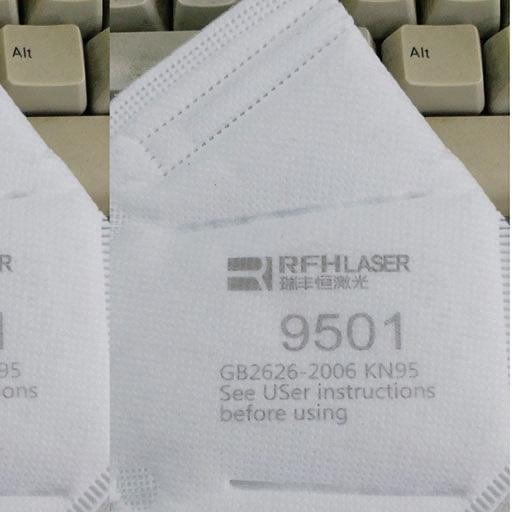

The Expert Ⅱ 355 series of UV diode pumped pulsed solid-state lasers developed and produced by RFH have a power range of 3.0w~5.0w, with short pulse width (<14ns@30K), superior beam quality (M2<1.2) and perfect The light spot characteristics (light spot ellipticity>90%), 13 years of technology accumulation, can be perfectly qualified for the ceramic marking job.

In addition to the advantages of the above products, RFH Laser also has the advantages of independent research and development of power supply technology, which can update the power control system function modules in time, and improve the function modules according to laser needs. As everyone knows, there is a one-to-one correspondence between the power supply and the laser, and the stability of the power supply control system determines whether the laser can maximize its performance during operation. This is an important reason why the entire RFH laser system is more stable than similar products.

The strength of RFH's UV lasers is due to the strong technical strength and rigorous quality management system mechanism behind it. Our technical research and development team is composed of professors, experts and doctors at home and abroad, and is strong. We set up an application process research and development department, a laser research and development department, and an electrical research and development department. We are obsessed with each process of the laser, and debug the stability of the whole system of power supply + laser + cooling system, so that it can maintain the stability under extreme industrial and scientific research conditions. The same stable quality, constant beam quality and high efficiency and durability.

Which light source is good for ceramic marking machine? We can confidently say that RFH brand UV lasers are the best choice!