UV laser marking ham sausage plastic packaging bag production date

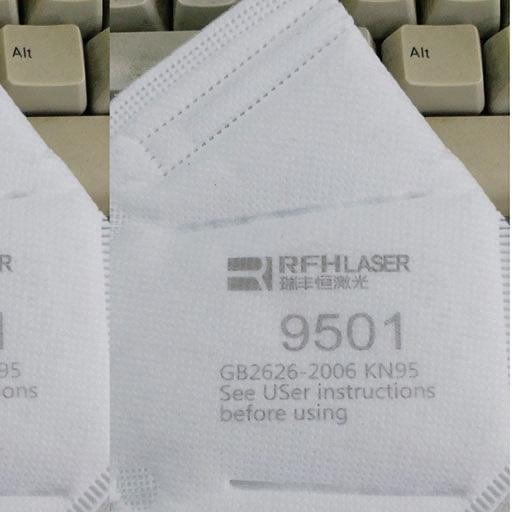

Warranty up to 18 months, marking on plastic outer packaging, choose RFH ultraviolet laser

RFH UV laser solves the problem of blurred dates printed on food plastic bags

People are paying more and more attention to food safety. Even children who buy a ham sausage know how to check the production date before buying to see if it is still in the shelf life. Therefore, as the facade of food products-outer packaging is very important. First of all, the raw materials used to make these outer packagings (mostly plastics) must comply with relevant regulations, and secondly, there are some advanced anti-counterfeiting technologies, such as production date marking using ultraviolet laser marking.

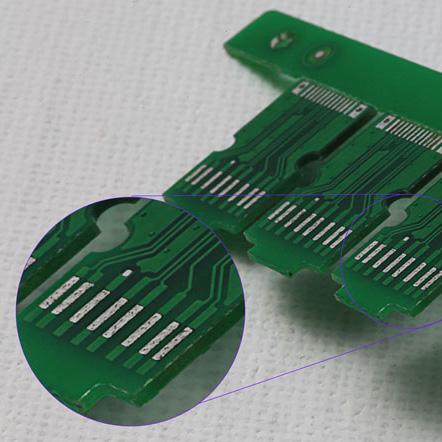

Why is there an anti-counterfeit production date mark with laser marking? Because these laser marking marks are permanent and will not fall off like ink and are easily erased, even if criminals have the idea of renewing the production date, they can't start. Because of this, UV laser marking has gradually become the main technology for date marking on the surface of plastic packaging bags.

At present, the market demand for laser marking of plastic packaging bags production date is very large in China, which has given birth to many brands of ultraviolet laser marking equipment. The lasers are mixed, and many manufacturers do not know how to choose. Now the editor will teach you how to select quality assurance!

First, look at the company's technical strength. For example, Shenzhen RFH has been in the UV laser industry for 12 years. Its R&D team is composed of professors, experts, and PhDs at home and abroad. It has obtained a number of technical patents and national certificates, and has established an application process R&D department, a laser R&D department and an electrical R&D department. Department, the strength is at the first-class level. Let you "stable" in mind.

Then, inspect the laser production materials and production process. RFH has a rigorous quality management system, level-by-level check, multiple inspections to ensure that the equipment parameters are consistent with the actual operating parameters, and for the entire production process in a dust-free workshop, the quality assurance is as long as 18 months, and the quality is guaranteed.

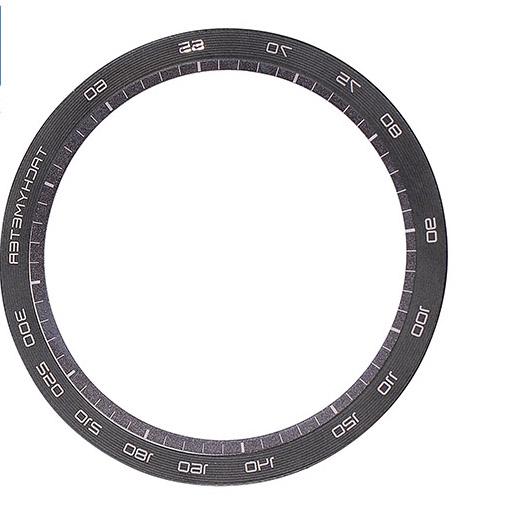

Finally, the editor recommends that you choose 4W-8W K-6 UV laser integrated machine. It has a unique Q-switching control technology, which is suitable for various laser application control requirements including ham sausage plastic packaging bag production date marking; it has an internal cavity self-purification system, which makes the laser long life; it can be used under extreme conditions in industry and scientific research , Maintain consistent stable quality, constant beam quality and efficient power consumption characteristics, fast marking speed, very suitable for high-speed assembly line flying marking processing.