RFH's 355nm ultraviolet laser is used in anti-counterfeiting masks

Why choose RFH UV laser for mask marking machine

RFH 355nm UV laser marking mask LOGO production date

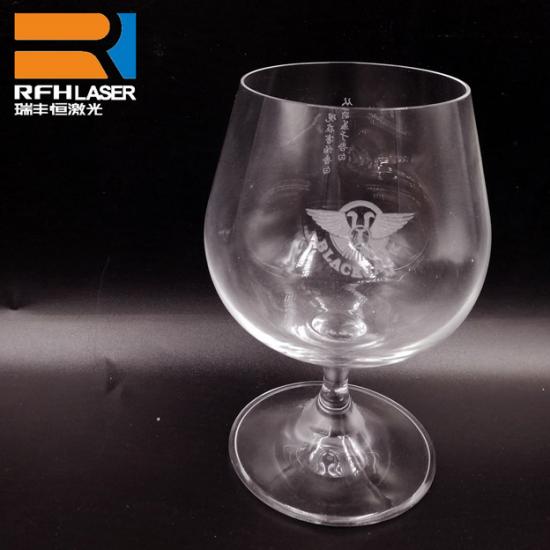

Mask marking machine needs to choose UV laser to realize marking and printing. Why is UV laser marking? It should be known that the material of this kind of melt blown cloth has a thin surface and is not easy to process in a hot environment. Other laser light sources will produce high temperatures during processing. Only UV laser marking can be adapted, so that 355mm UV cold is used for it. The light source does not produce high temperature during marking and will not cause damage to the mask. This type of light source has a small focus spot and is very suitable for marking delicate and small materials. This marking effect is not only clear and bright, but also There will be no stray ink and burrs, and it can be said that it is even better in marking.

Ultraviolet laser marking marks the LOGO production date, the breathing valve, including the packaging bag, is fast and stable. It can be combined with a streamlined production line to achieve laser coding and improve production efficiency.

For mask processing and marking, RFH’s 3.0w-5.0w Expert II 355nm UV laser can be used. The pulse width is short (<14ns@30K), the beam quality is superior (M2<1.2), and the spot characteristics are perfect (spot ellipticity>90%). It can maintain a consistent and stable quality under extreme industrial and scientific research conditions. Beam quality and high-efficiency power consumption characteristics. Therefore, even if the high-speed pipeline is continuously processed for a long time, there is no pressure, and the marking quality is still guaranteed.

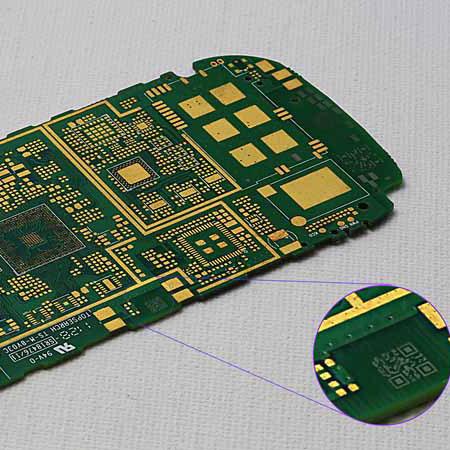

Moreover, the RFH 355nm ultraviolet laser is an integrated design with unique Q-switching control technology, which is suitable for a variety of laser application control needs. The range of materials that can be processed is not only mask materials, but also many.

Of course, in addition to the stable laser quality, the RFH 355nm UV laser is also very durable. We control from procurement-quality inspection before production-rigorous assembly process-finished product testing-warehousing quality inspection-inspection before delivery-after-sales service to ensure stable quality and consistency of equipment parameters with actual operating parameters. At the same time, there is also a professor and doctoral technical team that updates the function modules of the power control system in time, and improves the function modules according to the needs of the laser to ensure the long-term stable operation of the entire laser system.

After 13 years of hard work, RFH has won high recognition and a good reputation from users in all walks of life at home and abroad, and has established an excellent brand image in the nanosecond laser industry.