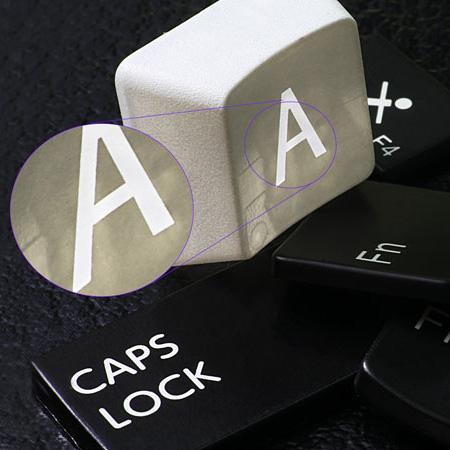

RFH 355nm UV laser non-contact marking chocolate packaging bag production date

For chocolate packaging bag marking production date, choose RFH UV laser

UV laser non-contact marking to ensure food safety

The most impressive Dove advertisement is the chocolate advertisement shot by Audrey Hepburn. It is elegant and temperamental, and beautiful to the bottom of the heart. Although there is no line, it makes people see the most beautiful appearance of love. In addition to the fragrant and silky smoothness of Defu Chocolate, the production date of the packaging is also non-contact marked with a UV laser, which provides a guarantee for food safety.

What is UV laser marking?

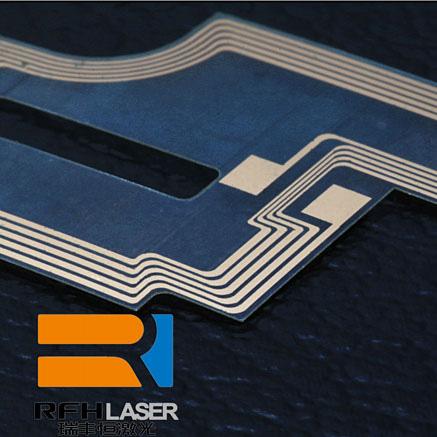

Ultraviolet laser marking is to use the laser thermal effect to ablate the surface material of the object, thereby leaving a permanent mark. It has the advantages of non-contact marking, low cost, no consumables, good permanence, no deformation, no pollution, high speed, high stability, and high precision engraving.

For example, the outer packaging of Dove chocolate is made of plastic material. Because of its minimal thermal influence, the UV laser can perfectly mark the production date without contact, preventing illegal businesses from altering the logo.

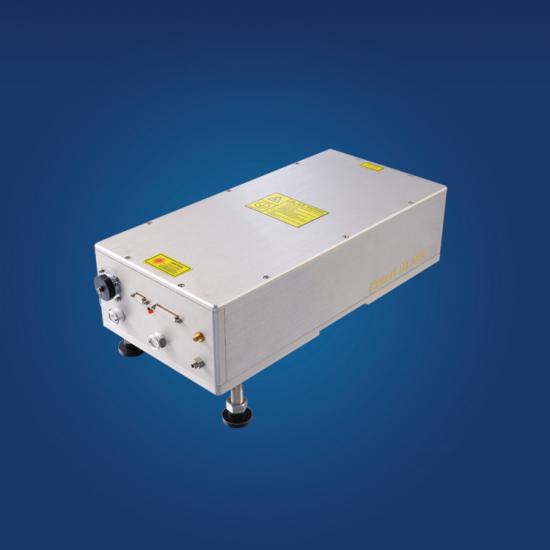

As a top laser manufacturer for 13 years in Seiko, RFH has developed and produced 355nm all-solid-state UV lasers using unique laser cavity design, acousto-optic Q-switching technology and high-precision cooling system, small size, high integration; pulse width < 20ns@40k, so the processing heat-affected area is small; the beam quality is superior (M2<1.2), which is strictly guaranteed in all frequency ranges; the spot characteristics are perfect (the spot ellipticity>90%). These parameters can remain consistent under extreme conditions in industry and scientific research.

Of course, for the plastics marking high-speed assembly line industry, marking quality alone is not enough, it must be efficient.

RFH This 355nm all solid-state UV laser just has both marking quality and marking efficiency. The integrated design makes it convenient for manufacturers to integrate equipment to suit various laser application control needs. It has a fully digital intelligent power control technology independently developed by RFH's professors and doctoral-level R&D team, which can update the power control system functional modules in time, and improve the functional modules according to laser requirements to maximize the performance of the equipment. Moreover, it supports communication with a computer, and can control the laser externally through RS232 to meet the needs of automated processing and production. Its excellence is all-round.

RFH has worked hard for 13 years and has achieved one after another first-class nanosecond laser, which has won high recognition and good reputation from users in all walks of life, and has made important contributions to my country's efforts to become a powerful industrial manufacturing country.