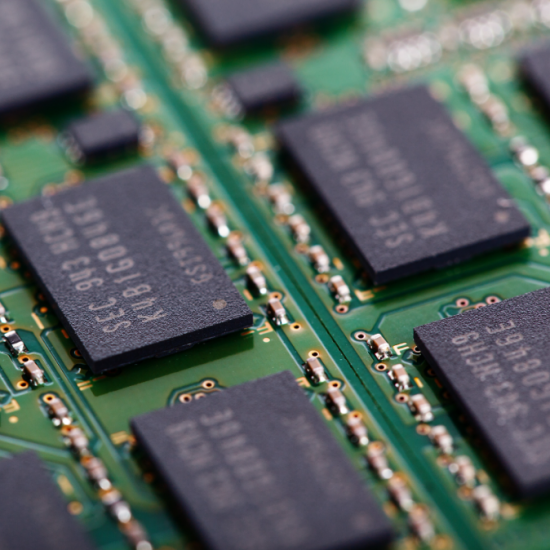

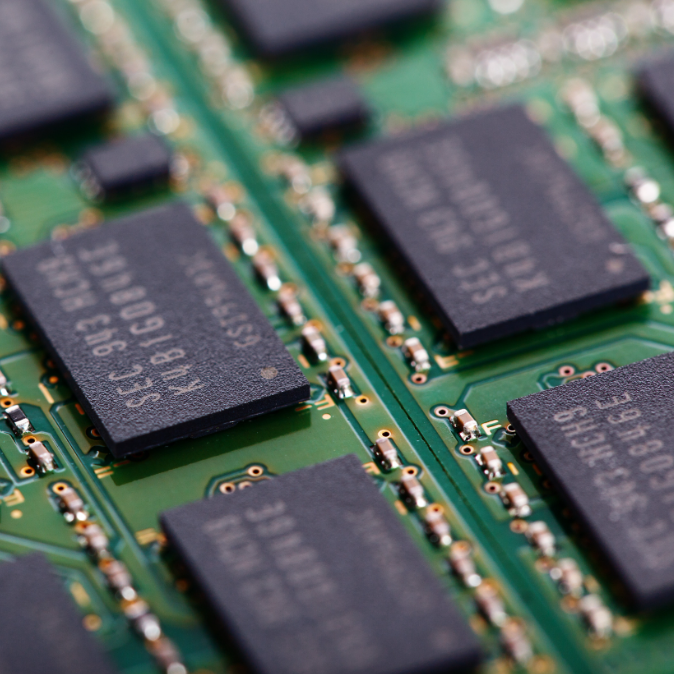

RFH 3W 5W DPSS Q-swiched UV Laser engraving IC chip

Boss Liu in Singapore owns an electronics factory. IC chips are often used in the factory. The inkjet printer used to print labels on the chips has become an indispensable thing. In recent years, just inkjet The machine changed several brands, and now it starts to advocate environmental protection production, so it starts to switch to laser marking.

The effect of laser marking is not easy to wear and fall off, which is several grades higher than inkjet coding. But after a period of time, Boss Liu encountered a problem again, the marking characters were not high-definition enough.

When we communicated with Boss Liu last month, we recommended RFH’s S9 3W 5W DPSS Q-swiched UV Laser to him based on the problems he encountered.

Compared with similar products, the S9 series is smaller in size, more refined in design, and more stable in light output. The small and exquisite design means that users do not need to enlarge the optical path, which can greatly reduce costs and save space, and can be easily installed in the field of flying marking equipment. S93W 5W DPSS Q-swiched UV Laser is not only small in size, but also has a more stable cavity structure and stronger expandability than similar products. The same cavity can generate lasers of various powers, and the stability of different power ranges has been greatly improved.

At the beginning of this month, during our after-sales return visit, Boss Liu said that our S9 3W 5W DPSS Q-swiched UV Laser has a very fine marking spot, which can engrave a logo that does not fall off, and the characters on the logo are clear and beautiful, and will not hurt The functional attributes of the chip can help him achieve mass production and be compatible with a variety of products of different specifications. In short, it is a good meal! !

Thank you Boss Liu for your strong support for RFH products.

The S9 3W 5W DPSS Q-swiched UV Laser, forged by RFH in 2016, has a high precision of ±0.02mm, which makes the beam quality higher, the performance is better, and it helps precise processing; and the power stability is high, the efficiency and repetition frequency are high, and the power is higher. It is stable, has a longer service life, and injects strong power into continuous processing. Such a product has both appearance and connotation. You deserve it!