Website: http://www.rfhtech.com

Whatsapp(Wechat): 18928466502

Email: export06@rfhlasertech.com

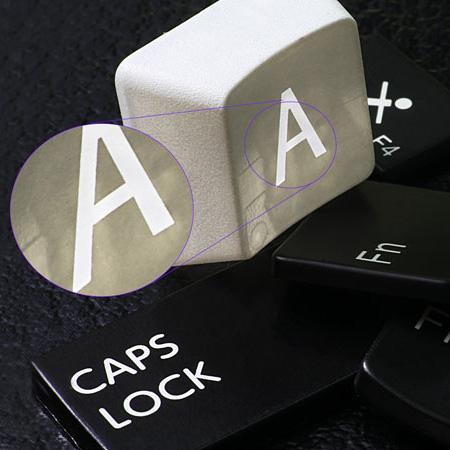

RFH nanosecond uv ultraviolet laser cut PCB, copper foil of battery, accurate and fast

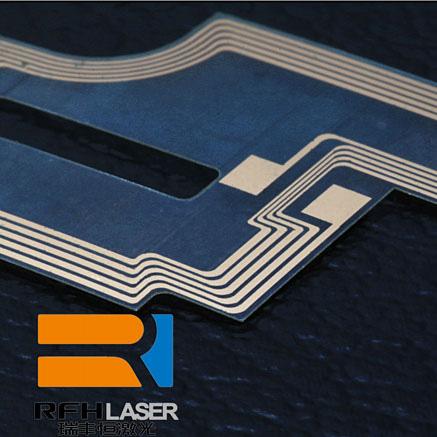

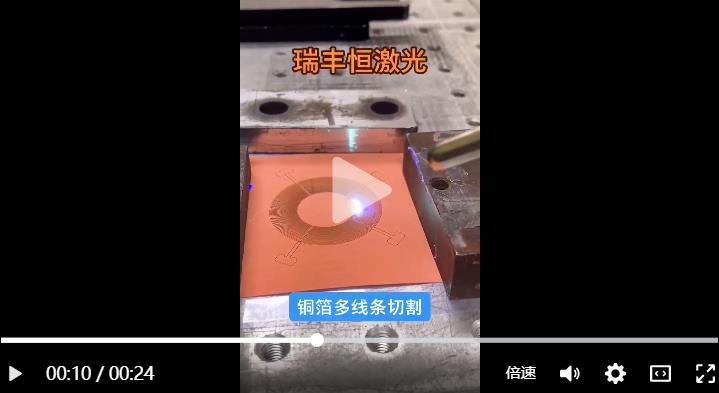

pretty! RFH 355nm UV laser cutting copper foil multi -line

Which do you think is more difficult to process precision materials and large machinery?

Looking at the copper foil with only micron (UM) thickness in your hand, RFH is easily completed through ultraviolet laser, cutting off the high accuracy, smooth edges and no burrs, and no signs of carbonization. It is perfect!

Materials such as copper foil are absolute necessities in the field of PCB and battery, and they are also one of the most important electrolytic materials.

Facing this ultra -thin metal processing, the difficulty of processing is no less difficult than various large machinery.

As the degree of digitalization gradually deepen, copper foil, which is a PCB substrate and battery electrolyte, has gradually become the darling of industry.

However, due to the difficulty of processing, during the period of "traditional knife mold cutting", there are no small problems in the aspects of cutting speed, accuracy, and knife mold loss.

But looking back at the development process, after using ordinary laser as soon as possible, things were not as smooth as everyone imagined, and they also encountered many problems during processing.

Because the impact of ordinary laser heat is great, it is found in the actual use that the cut edges are easy to encounter burrs, deformation and other problems, and even improper power control will have carbonization problems.

Because copper foil is too thin, everyone is anxious to find a perfect solution. This is shown by the beginning of the article -RFH UV laser cutting.

Because ultraviolet laser belongs to the "cold laser light source", it has the advantages of small thermal impact. The processing accuracy is high, the edges are smooth and without burrs, and it is a perfect match with the cut ultra -thin alloy.

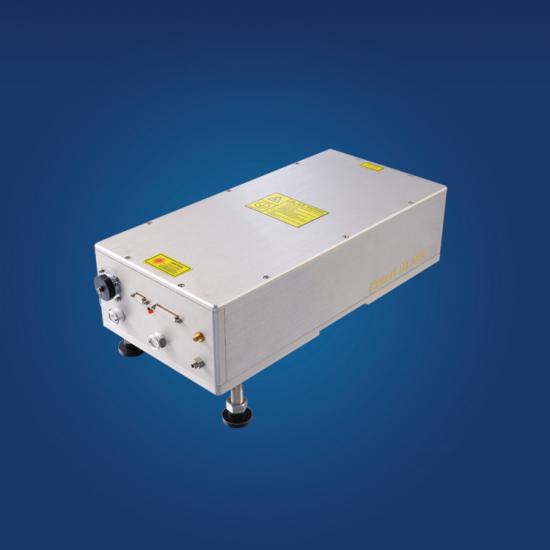

RFH Ultraviolet Laser Recommendation: Expert III 355 high -power UV pulse solid laser

RFH Expert III 355 is a high -power UV laser (10W ~ 15W), so it can also improve efficiency based on high -precision processing.

In terms of design concepts, RFH Expert III 355 makes it convenient to integrate with various devices through high integration and small volume.

It is because the RFH Expert III 355 is small, so there is no need to do a big light road. In addition, thanks to the unique laser -cavity design, sound and light -adjustment Q technology, etc., it has the advantages of high stability, long life, and high processing accuracy.

Through the superior beam quality (M2 <1.2), the RFH Expert III 355 can be strictly guaranteed within all frequencies, and the pulse width is <25ns@50K.

Facing the later operation and maintenance personnel, the RFH Expert III 355 uses a full digital power control technology. It can communicate with the computer with the RS232 serial port. It is simple and easy to monitor.

RFH constant technical advantage: power control system

After more than 15 years of technical accumulation, RFH already has a doctoral team. Through the self -developed power control system, the RFH laser has unparalleled stability and service life

Because the performance of the power supply and the laser performance is the corresponding relationship, RFH has the advantages of independent research and development of the power supply technology, which can flexibly improve the functional module according to demand, and also achieve the backing of the RFH laser stable operation.

On the core components, RFH uses imported brands, and parts also cooperate with domestic front -line suppliers, so they are at the top level of the industry in terms of quality and quality.

RFH laser has an unchanged core technical advantage. Whether facing large machinery or precision processing, there is no pressure, bringing you the most efficient and accurate experience.