RFH UV laser is used for KN95 mask marking, less than one second

3W5W UV laser marking KN95 mask date and information

355mm UV cold light source, will not damage the mask

With the spread of the epidemic around the world, people's demand for masks continues to increase, and major mask manufacturers are also working hard to increase the production of masks. Among them, mask marking is an indispensable and important part of the production process. The printing mark of KN95 masks is generally printed on the outside of the mask. The content on it generally includes the mask model, related certificates, production date, etc., which is an important means of inspecting the quality and quality of the mask.

Consumers rely on marking to identify the authenticity of masks, and overseas countries rely on marking to identify whether masks comply with local medical regulations. Since marking is so important, how to choose the mask production process and supporting equipment?

Inkjet marking VS laser marking

At present, the common marking processes on the market include inkjet marking and laser marking. For medical supplies such as masks, UV laser marking should be preferred. Why is UV laser marking?

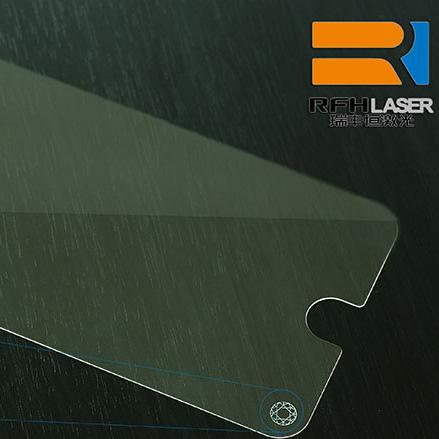

It should be known that the material of meltblown cloth used in masks has a thin surface and is not easy to process in a hot environment. Some laser light sources will generate high temperatures during processing, and UV laser marking can be very well adapted. The release of 355mm Ultraviolet cold light source will not produce high temperature during marking and will not cause damage to the mask. This type of light source has a small focus spot and is very suitable for marking delicate and tiny materials, so that the marking effect is not only clear and eye-catching. , It will not appear scattered ink and burrs, it can be said that it has many advantages in marking.

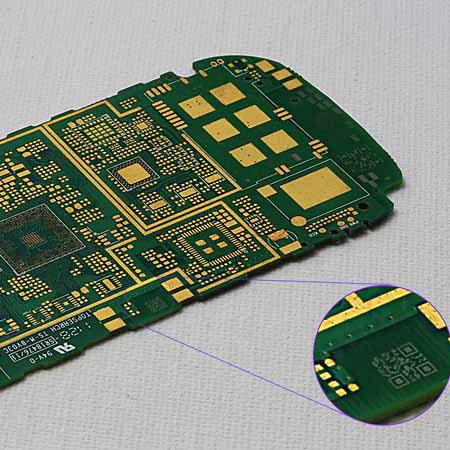

Ultraviolet laser marking can meet the needs of marking the LOGO, production date, breathing valve, and packaging bags of masks such as N95 and KN95. It can improve production efficiency and has excellent results. Among them, it is particularly important to choose ultraviolet solid-state lasers in industrial applications.

How to choose high-quality solid-state lasers?

A good UV solid-state laser should have the following advantages:

One, high precision. Ultraviolet lasers are often used for micromachining, and higher precision can ensure the accuracy and integrity of marking.

Second, it is convenient to install and maintain. Many lasers are cumbersome to install, and corporate purchases often take a lot of time to debug and install, which greatly occupies the development and maintenance costs of the enterprise. The excellent laser circuit design is simple, easy to install, and uses CNC control, which makes it easy to get started.

Third, the stability is high. A good ultraviolet laser usually has a wavelength below 0.4μm, a stable beam, and a balanced energy control. It can effectively micro-process the polymer material without showing signs of burn damage to the material.

KN95 mask laser marking is completed in 1 second

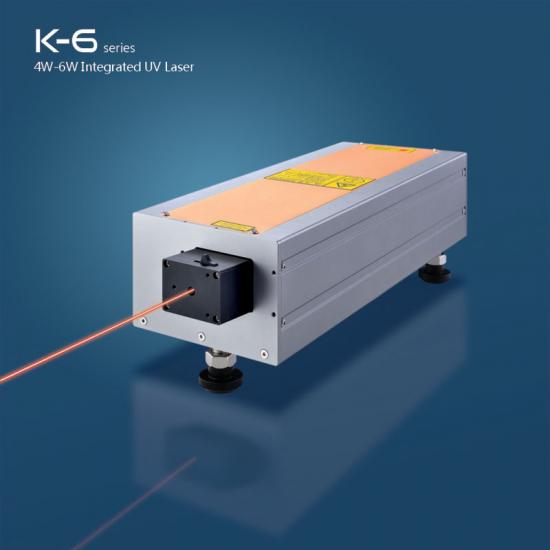

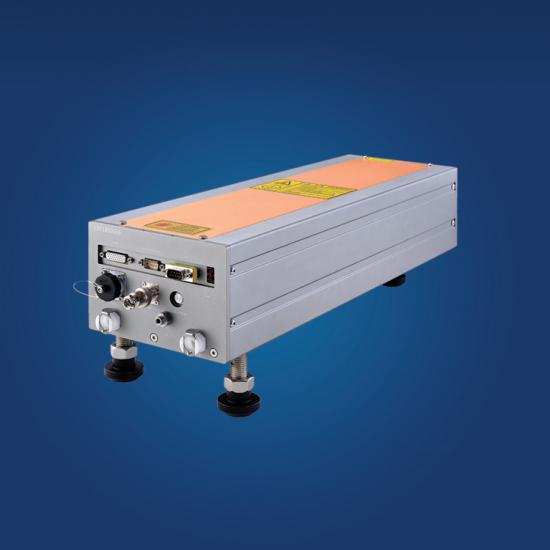

Combining the above characteristics, RFH UV laser is an ideal choice.

RFH Expert Ⅱ 355nm UV laser has a laser wavelength of 354.7nm and a wide range of repetition frequency (single pulse to 200kHz), which can be better absorbed by the material and is less destructive to the material. At the same time, it has superior beam quality (M2<1.2), which is strictly guaranteed in all frequency ranges; pulse width <20ns@30k, the heat-affected area during processing is small, and it supports digital intelligent power control, simple operation, low hands-on cost, Suitable for various laser application control needs.

RFH Expert Ⅱ 355nm UV laser has many advantages in mask marking applications:

Sterile and environmentally friendly, 0 pollution

The identification code never falls off

The handwriting is clear and legible

Facilitate anti-counterfeiting and full traceability of mask products

Complete in 1 second, convenient and efficient

At present, many large-scale mask industry chains have used RFH UV lasers for mask marking and anti-counterfeiting. The trust of customers is RFH's eternal pursuit. As the epidemic intensifies overseas, RFH laser will invest more technology to help mask quality.