355nm ultraviolet UV laser module marking charger adapter on surface

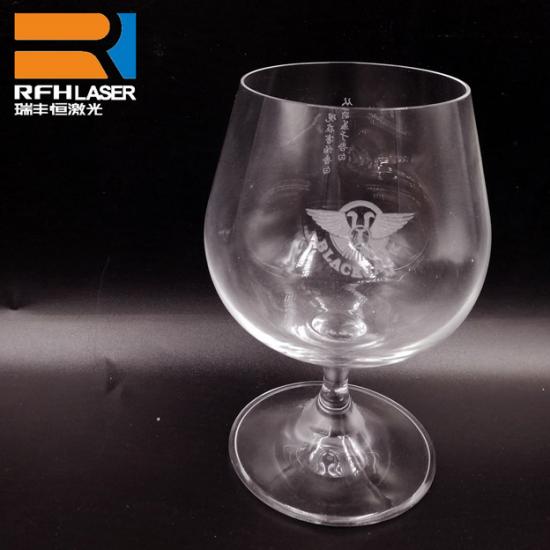

Some time ago, the editor of RFH Laser went to several exhibitions in the industrial machinery manufacturing industry and found a trend: there are fewer and fewer silk screen application industries, and now only the clothing industry and the advertising industry are still in use. Back then, the application range of silk screen printing was so wide. Fabrics, plastics, metals, ceramics, glass, electronic products, prints, almost everything can be printed. With the improvement of the industry's requirements for printing quality and the country's requirements for environmental protection, many silk screen printing processes have been replaced, such as the printing of electronic products.

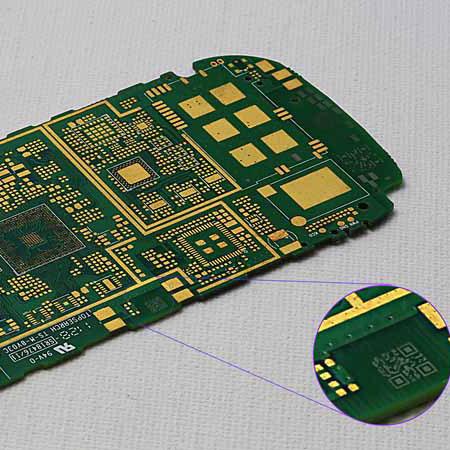

The printing of electronic products, such as charging adapters, is mainly to mark some logos, QR codes, production dates and other information on the surface. The silk screen printing process used in the past, the finished product is relatively clear and beautiful, but with the increase of use time, the above information will gradually disappear - the silk screen paint is worn away. Surely this is not enough? As a result, a better process came out. That is laser marking technology.

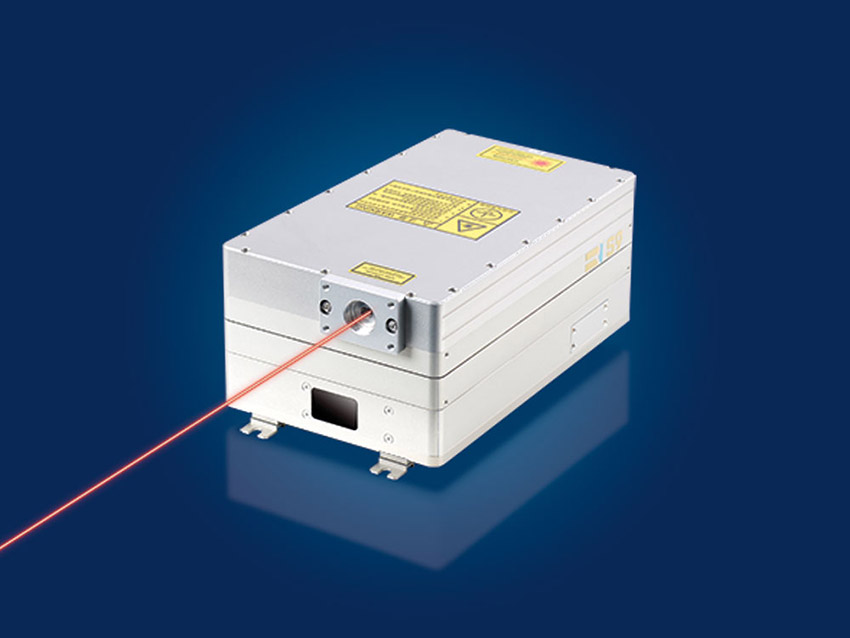

Laser marking is to use a beam of high-energy light to burn the surface of the object to be marked to form traces, that is, marks. At first, some people questioned, wouldn't such a high laser energy burn things? No, as long as we control the beam energy within a certain range. Ultraviolet laser is the mainstream marking equipment with this effect. However, there are not many companies that can produce this kind of ultraviolet laser equipment, and RFH is one of them.

If you want to have a stable and fine marking effect, the laser must first be stable enough. For example, RFH's 355nm ultraviolet UV laser module has excellent and stable beam quality (M2<1.2), which is strictly guaranteed in all frequency ranges; at the same time, its pulse width is short (<14ns@30K), and its spot characteristics (spot ellipticity>90%) , to ensure fine marking effect. Then, it has to be durable. After all, the price of ultraviolet lasers is not cheap, and laser marking is an industry with small profits but quick turnover, so only durable lasers are really good lasers.

In addition to stable performance, RFH's UV laser has another feature, that is, it is durable. This feature has accumulated 12 years of hard work by the RFH expert team. We have set up a top laser research and development team composed of domestic and foreign professors, experts and doctors, and set up application process research and development departments, laser research and development departments, and electrical research and development departments to continuously innovate and optimize product quality, so we have today's series Top quality lasers.

In the past 16 years, we have obtained patent certificates and computer software copyright certificates issued by the state many times, and won certificates such as "National High-tech Enterprise", "Shenzhen High-tech Enterprise", "Software Enterprise Certification" and other certificates. The Innovation Alliance and the Guangdong Laser Industry Association have been appointed as the governing units. At the same time, they have also won high recognition and good reputation from users from all walks of life at home and abroad, and have established an excellent brand image in the nanosecond laser industry.