355nm UV laser cutting plastic parts

When processing plastic casting products, a series of connected or disconnected plastic columns will be formed at the pouring point when entering the mold. These plastic columns are commonly known as "spouts".

I still remember that when we assembled toys when we were young, we would encounter excess parts when we removed the parts, and we would find a way to remove them, because these plastic parts are not part of the product. During industrial processing, the "spout" is not part of the product, and the extra part must be cut off.

The cutting nozzle of industrial processed products is no better than our assembly model. For a qualified product, the nozzle part must be cut smoothly without burrs, and it must be cut precisely.

How to cut the nozzle of plastic parts?

At this time, you need to use a professional "water nozzle cutting machine". Do you still use sharp knives now? Of course not, firstly, the consumables are expensive, and secondly, the accuracy cannot be guaranteed. The most common one in modern industrial production is "ultrasonic water cutting machine".

In large-scale production, the traditional ultrasonic water cutting nozzle uses ultrasonic waves to generate high-frequency vibrations in the nozzle part, and molecular friction generates heat, which eventually causes breakage in the nozzle part.

Facing the processing of plastic parts, it is just a word - "heating", but the temperature must be controlled reasonably, otherwise it will affect the smoothness of the cut part. Therefore, the ultrasonic nozzle cutting machines seen in daily industrial production are all huge in size, not only because generating enough ultrasonic waves requires a lot of energy, but also controlling the accuracy of ultrasonic energy is also a matter of knowledge.

When ultrasonic cutting is used for nozzle cutting, the work efficiency and cycle time are greatly improved, but the problem is also obvious-the cutting machine is too large.

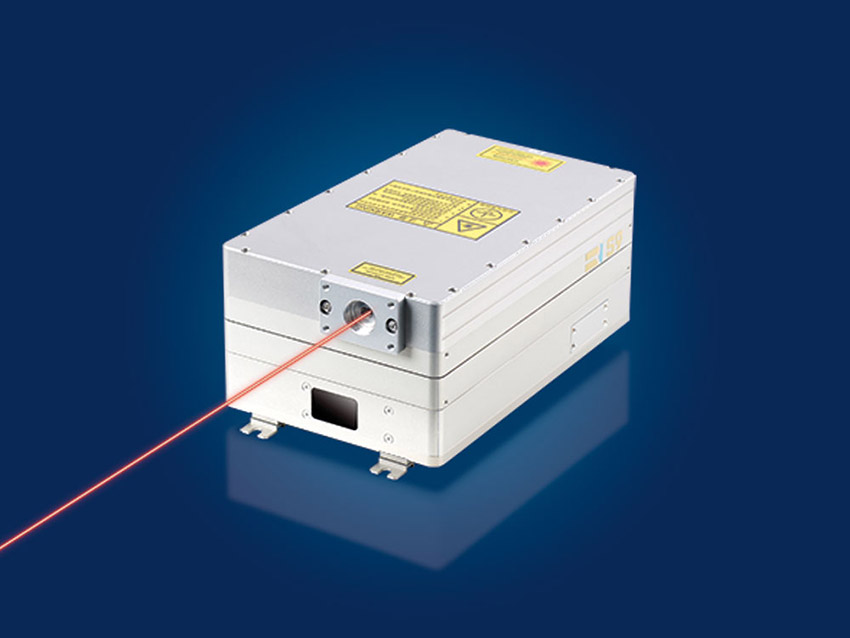

Low-cost, high-efficiency, high-precision laser cutting (RFH S9 series UV laser)

In the face of large-scale production, the excessively large volume and huge energy consumption ratio have resulted in high costs. Is there a better way?

RFH UV laser cut plastic nozzle is a better choice.

As a leading company in the laser industry, RFH has never stopped digging in laser applications. Facing the problem of plastic parts notch, laser that can be precisely controlled is a better choice.

RFH's latest S9 series UV laser has a small size and a highly integrated modern industrial design, which saves processing costs, is simple to install, saves space, and can be used directly without enlarging the optical path. Compared with the huge ultrasonic nozzle cutting machine, RFH S9 series UV laser has unparalleled advantages.

Of course, with such a small size, the RFH S9 series UV laser still achieves extremely high precision control, and the cutting error is controlled within ±0.02mm, even for the processing of small parts.

For the processing of plastic parts, the control of laser power is also the top priority. RFH S9 series UV laser has a very stable cavity structure, and also has patented technology in terms of power supply. As an industry leader, extremely high laser quality is RFH's killer feature .

The laser parameters under full digital control can fine-tune the incision power, and all operations are completed on the computer. This full digital control power supply method has a more intuitive display, ensuring that the cutting nozzle is smooth and burr-free.

After 15 years of development, RFH laser can bring excellent solutions to all kinds of precision machining.

The newly launched RFH S9 series UV laser

It takes this advantage to a whole new level.

The compact size and high-quality laser have become the benchmark of the industry,

Experience high-quality products and perfect pre-sales and after-sales,

All in RFH Laser!